Pipeline blocking monitoring device and method for paste filled pipeline

A paste filling and monitoring device technology, applied in measuring devices, instruments, material analysis by electromagnetic means, etc., can solve the problems of complex structure and high sensitivity requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

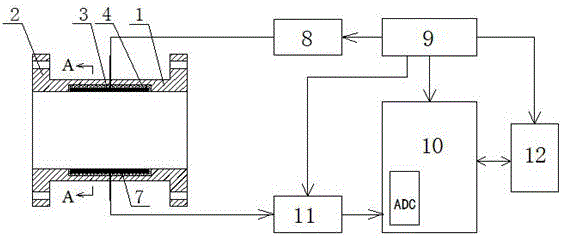

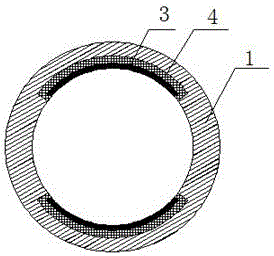

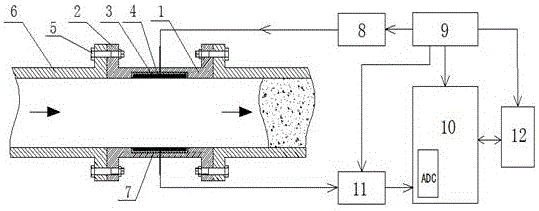

[0026] Such as figure 1 As shown, a paste filling pipeline blockage monitoring device includes a monitoring pipeline 1, a resistivity testing device, and an insulating gasket 4; the upper and lower inner walls of the monitoring pipeline 1 are respectively opened with mutually symmetrical circles with the same radius of curvature as the pipeline. Arc-shaped groove; a resistivity test device is set in the arc-shaped groove; the resistivity test device includes an upper electrode 3, a lower electrode 7, a constant current source 8, a signal amplifier 11, a single-chip microcomputer 10, a PC computer 12, a power supply 9. The upper and lower electrodes are respectively installed in the upper and lower grooves on the inner wall of the monitoring pipeline 1, wherein the upper electrode 3 is connected to the constant current source 8, the lower electrode 7 is connected to the inlet port of the signal amplifier 11, and the outlet port of the signal amplifier 11 is connected to The sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com