Germanium-based gallium arsenide multi-junction flexible film solar cell and preparation method thereof

A flexible thin film and solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as limited application scope, achieve good flexibility, light weight, and improve the application range and weight-to-weight ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

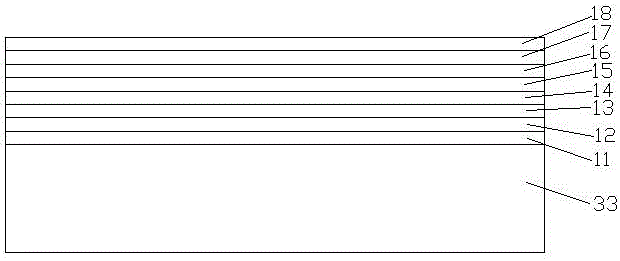

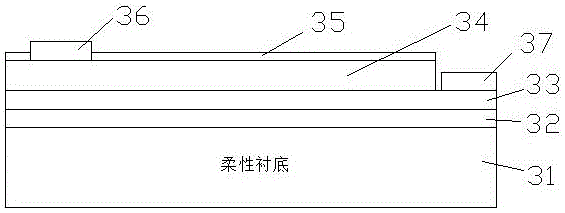

[0039] First, the production process, such as figure 1 , 2 , as shown in 3:

[0040] 1. Epitaxial wafer growth:

[0041]The N-type GaInP nucleation layer is sequentially grown on the P-type Ge substrate 33 with a thickness of 175 μm by MOCVD equipment to form the bottom cell 11, the N-type GaAs buffer layer 12, the first tunnel junction 13, the InGaAs middle cell 14, and the second tunnel junction. Junction 15, GaInP top cell 16, N-type AlInP window layer 17 and N-type GaAs contact layer 18 complete the growth of the epitaxial wafer, and the formed battery epitaxial wafer structure is as follows figure 1 shown.

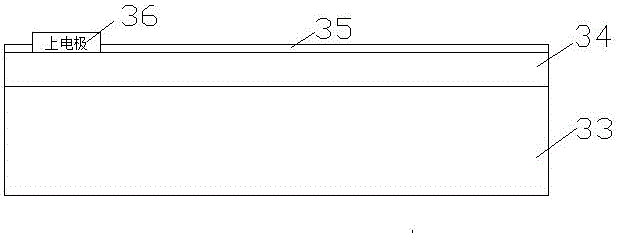

[0042] 2. Production of the upper electrode:

[0043] Such as figure 2 Shown:

[0044] The battery epitaxial wafers that have completed the off-line engraving are cleaned by organic ultrasonic cleaning with acetone and alcohol, and after QDR cleaning and spin-drying, the negative photoresist process is used for electrode grid patterns such as yellow light coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com