Intelligent pressure welding platform suitable to high voltage power transmission lines

A technology of high-voltage power transmission and wires, applied in the direction of circuits, connections, electrical components, etc., to achieve the effects of improving efficiency, facilitating use, reducing investment and construction work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

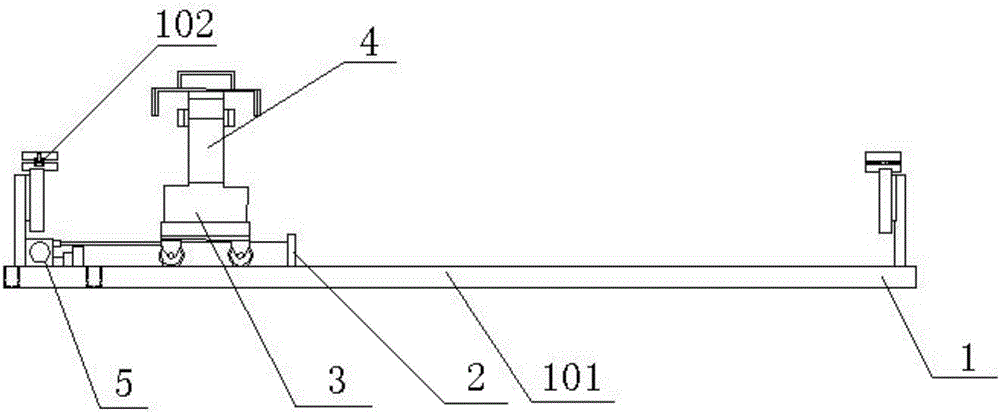

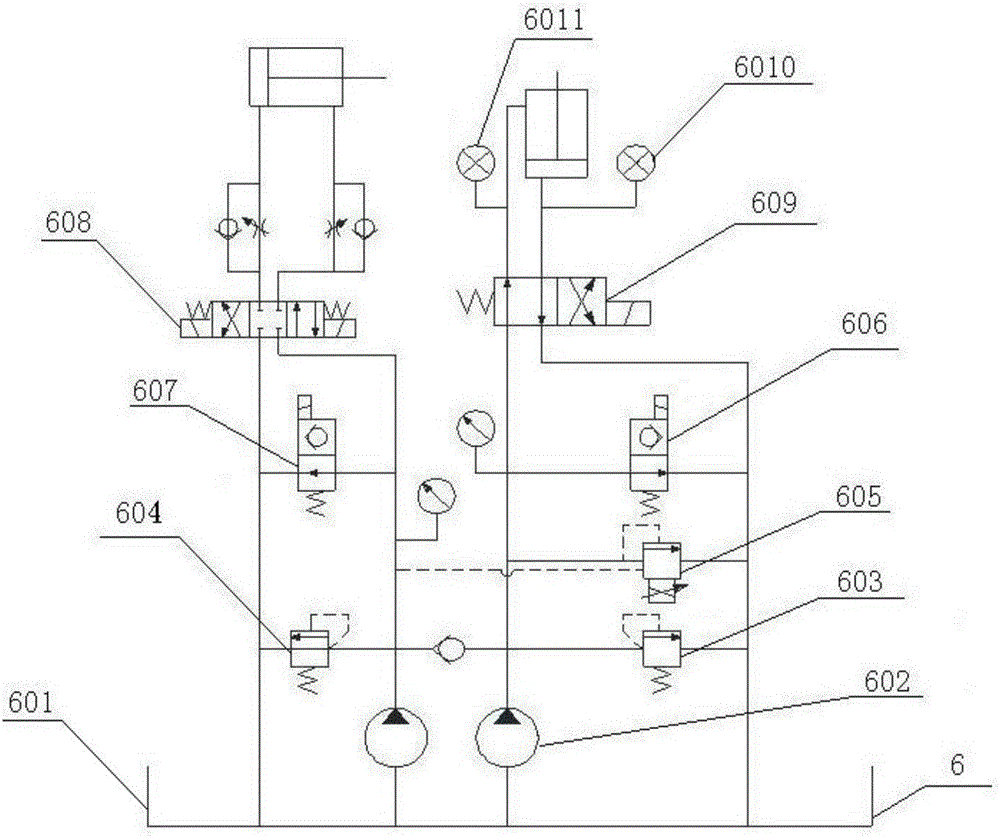

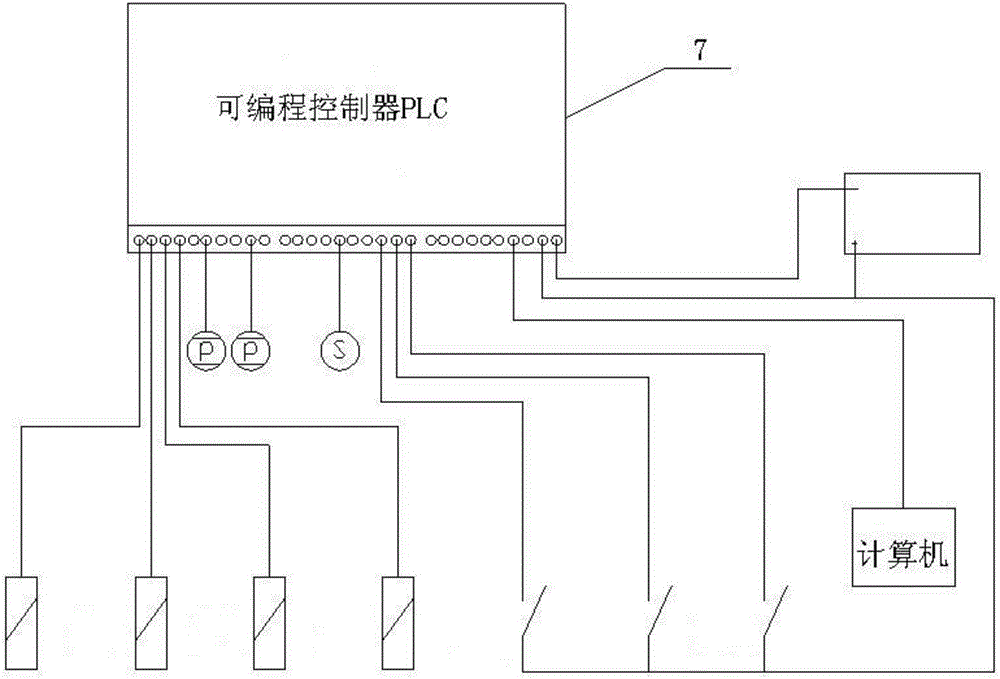

[0026] The invention provides an intelligent crimping platform suitable for high-voltage power transmission wires, which includes a rail-type crimping bracket 1, a horizontally moving oil cylinder 2, a crimping pliers trolley 3, a crimping pliers 4, a displacement sensor 5, a gasoline engine hydraulic pump 6 and a programmable A controller 7, wherein the press clamp 4 is a hydraulic press clamp,

[0027] Such as figure 1 , figure 2 and image 3 As shown, in order to ensure the accuracy of crimping, the curvature of the crimping tube, and reduce the damage caused by manual operation, the present invention designs and manufactures a rail-type crimping bracket 1, and the rail-type crimping bracket 1 includes a base 101 and Wire clamps 102, wherein the number of wire clamps 102 is two, and the two wire clamps 102 are respectively arranged on the two ends of the base 101, and the wires are positioned on the two wire clamps 102 when performing the crimping operation, and the wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com