Field electric power overhaul frame

An electric power maintenance frame and field technology, which is applied in the direction of electrical components, overhead lines/cable equipment, switchgear, etc., can solve the problems of many dangerous points, tight construction schedules, heavy tasks, and potential safety hazards at the power maintenance construction site, so as to save storage space , high security, enhanced stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

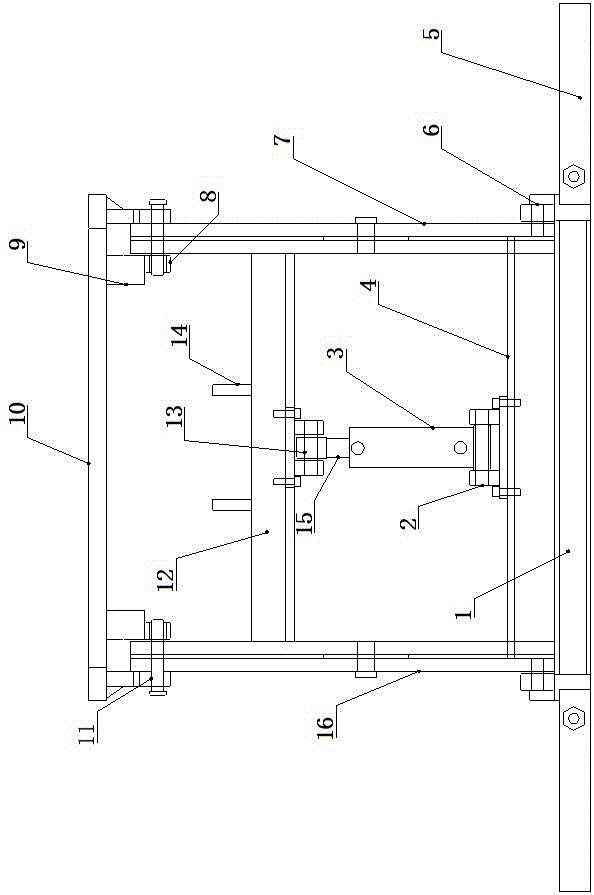

[0014] Such as figure 1 As shown, a kind of electric maintenance stand for field use, it comprises base 1, and the left and right ends of described base 1 are all connected with extension bar 5, and the upper side of the left end of described base 1 is connected with column A16, and described base The upper side of the right end of 1 is connected with a column B7, and the outer side of the connection between the column A16 and the column B7 and the base 1 is provided with a reinforcing seat 6, and the upper side of the middle part of the base 1 is provided with a support rod 4. The upper side of the middle part of the support rod 4 is provided with a mounting base 2, and the upper side of the mounting base 2 is provided with a hydraulic cylinder 3, and the upper end of the hydraulic cylinder 3 is connected with a piston rod 15, and the piston rod 15 is The top is provided with a support 13, and the upper end of the support 13 is provided with an inspection platform 12. The ins...

Embodiment 2

[0017] Such as figure 1 As shown, a kind of electric maintenance stand for field use, it comprises base 1, and the left and right ends of described base 1 are all connected with extension bar 5, and the upper side of the left end of described base 1 is connected with column A16, and described base The upper side of the right end of 1 is connected with a column B7, and the outer side of the connection between the column A16 and the column B7 and the base 1 is provided with a reinforcing seat 6, and the upper side of the middle part of the base 1 is provided with a support rod 4. The upper side of the middle part of the support rod 4 is provided with a mounting base 2, and the upper side of the mounting base 2 is provided with a hydraulic cylinder 3, and the upper end of the hydraulic cylinder 3 is connected with a piston rod 15, and the piston rod 15 is The top is provided with a support 13, and the upper end of the support 13 is provided with an inspection platform 12. The ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com