Imaging mechanism and terminal

An imaging and housing technology, applied in the field of image shooting, can solve the problems of inconsistent image clarity, camera aberration, focusing failure, etc., to avoid focusing failure, reduce the aberration, and achieve consistent image clarity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

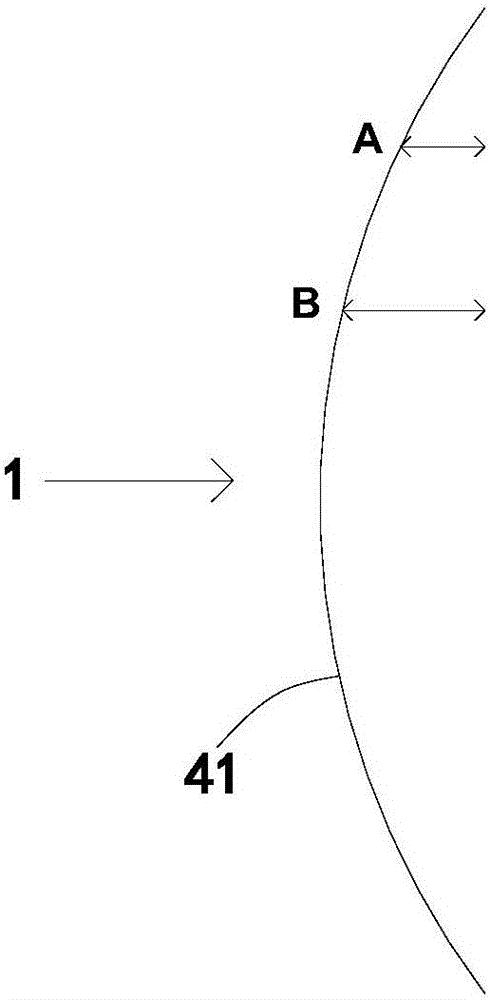

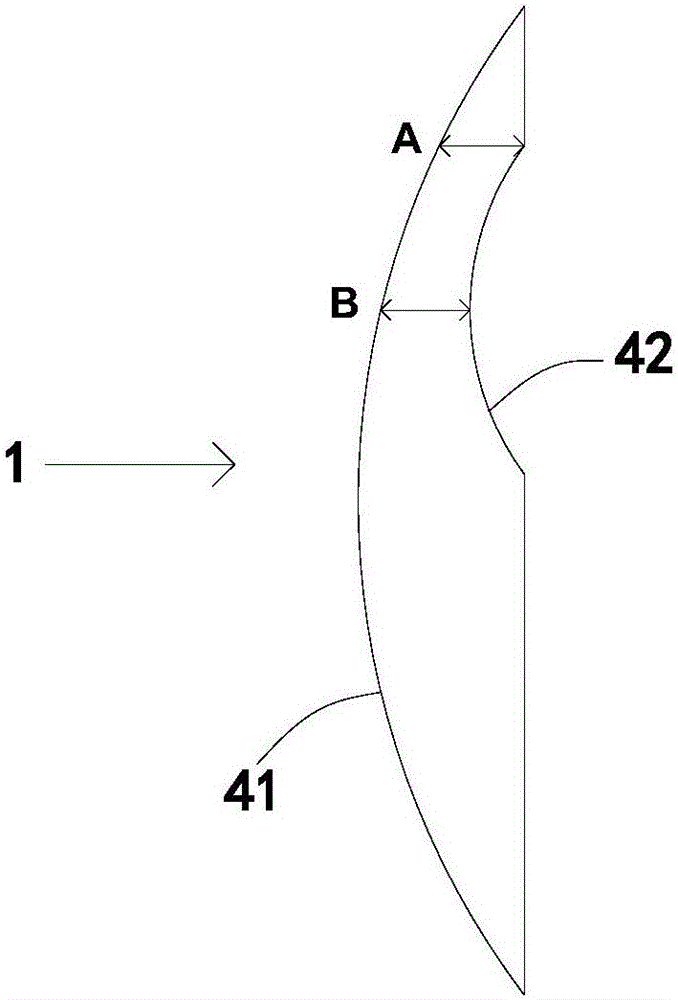

[0040] An imaging mechanism, comprising a glass cover 1 and a camera 2, one side of the glass cover 1 protrudes outward to form a first arc 41, the other side of the glass cover 1 is opposite to the camera 2, The glass cover 1 is provided with a second arc surface 42 at the position opposite to the camera 2, and the second arc surface 42 is formed by inward depression at the position opposite to the camera 2 of the glass cover 1, and the The distance between the first arc surface 41 and the second arc surface 42 is the same, the camera 2 is aimed at the area where the distance between the first arc surface 41 and the second arc surface 42 is the same, and the second arc surface 41 The coverage of the curved surface 42 is larger than the shooting range of the camera 2 .

Embodiment approach 2

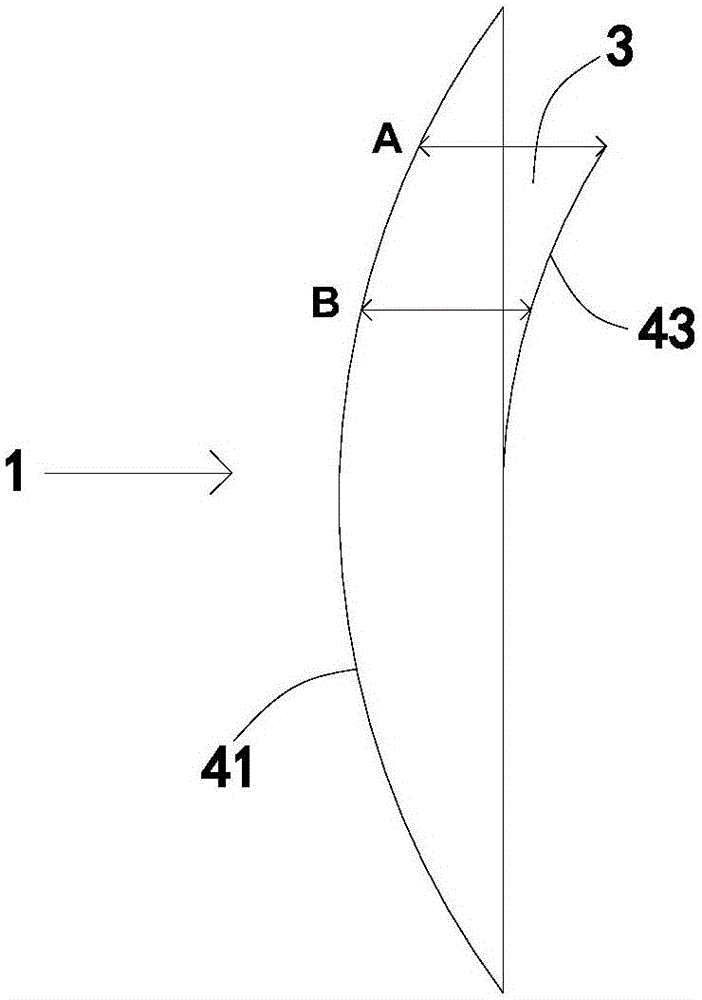

[0042] An imaging mechanism, comprising a glass cover 1 and a camera 2, one side of the glass cover 1 protrudes outward to form a first arc 41, the other side of the glass cover 1 is opposite to the camera 2, The glass cover plate 1 is provided with a glass sheet 3 opposite to the camera 2, a transparent glue layer is arranged between the glass cover plate 1 and the glass sheet 3, and the glass sheet 3 passes through the transparent glue layer. layer is adhered on the glass cover 1, wherein the glass cover 1 and the glass sheet 3 have the same refractive index; in addition, the glass sheet 3 is recessed inwardly opposite to the camera 2 to form a second Three arc surfaces 43, the distance between the first arc surface 41 and the third arc surface 43 is the same, and the camera 2 is aligned with the same distance between the first arc surface 41 and the third arc surface 43 area, and the coverage of the third arc surface 43 is larger than the shooting range of the camera 2 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com