Variable-resistor plate for liquid level detector, variable-resistor plate production method, and liquid level detector

A technology of liquid level detection and resistors, which is applied in the direction of resistor manufacturing, resistors, measuring devices, etc., and can solve problems such as resistance value deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

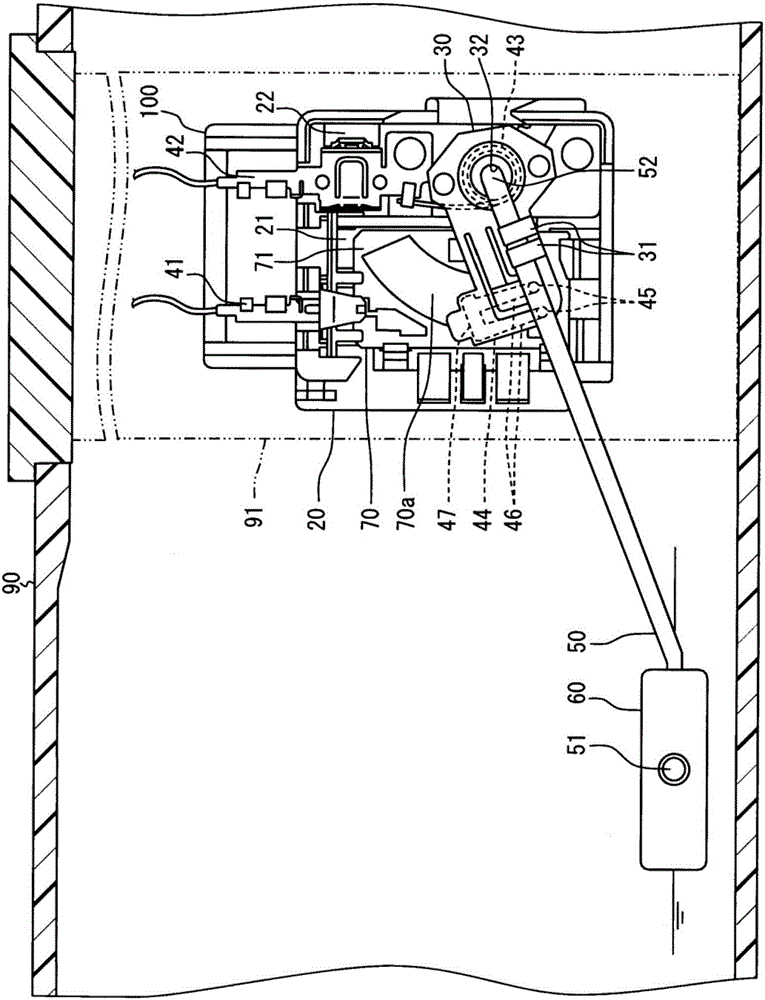

[0023] Such as figure 1 As shown, the liquid level detection device 100 of the first embodiment is installed in a fuel tank 90 that stores fuel as a liquid. The liquid level detection device 100 detects the height of the liquid level of fuel stored in the fuel tank 90 while being held by the fuel pump module 91 or the like. The detection result detected by the liquid level detection device 100 is output to a combination meter (not shown), and the combination meter notifies the driver.

[0024] The liquid level detection device 100 is composed of a float 60 , a float arm 50 , an arm support 30 , a housing 20 , a variable resistor plate 70 and the like.

[0025] The buoy 60 is formed, for example, of a material having a specific gravity lower than that of fuel, such as foamed hard rubber. The buoy 60 can float to the liquid surface of the fuel by buoyancy obtained from the fuel. The buoy 60 is held by the buoy arm.

[0026] The float arm 50 is formed of a round rod-shaped co...

no. 2 approach

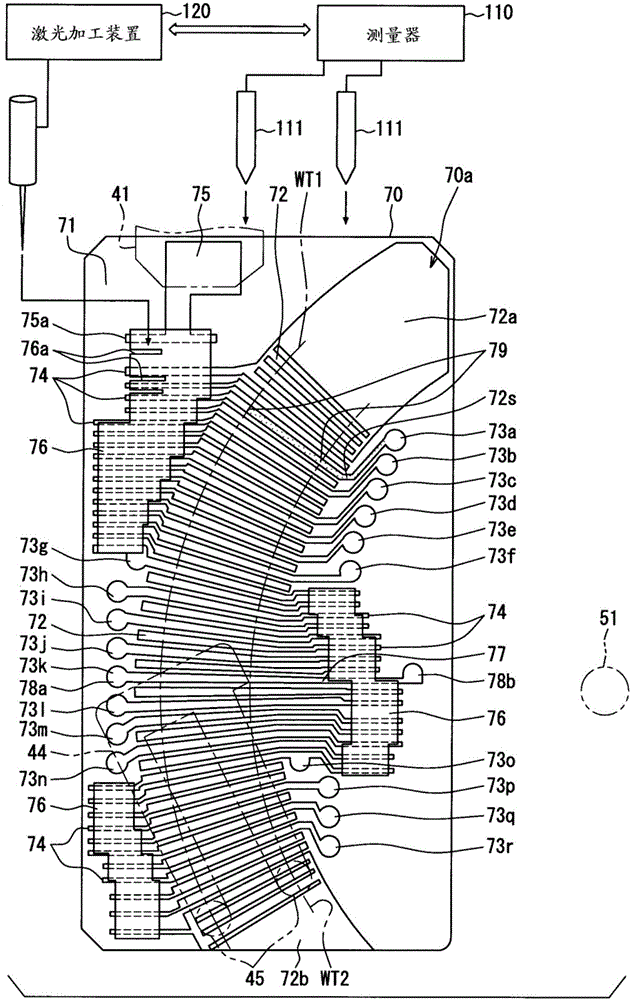

[0059] Figure 4 The illustrated second embodiment is a modified example of the first embodiment. The resistance circuit 270a of the variable resistor board 270 of the second embodiment is provided with a connection electrode 275, a sliding electrode 272, and a resistance element 276 corresponding to the respective configurations 75, 72, and 76 of the first embodiment. In addition, the correction electrode 277 of the second embodiment is formed on the substrate main body 271 independently of the slide electrode 272 .

[0060] The correction electrode 277 is formed so as not to overlap the slide electrode 272 in the removed portion 272c provided in the region 272a. The correction electrodes 277 are provided at positions not in contact with the respective sliding contacts 45 of the sliding plate 44 . The correction electrode 277 extends in a belt shape in the radial direction of the rotating shaft portion 51 . The correction electrode 277 forms a pair of correction pads 278a ...

no. 3 approach

[0068] exist Figure 5 In the third embodiment shown, the correction electrodes 377 are not formed on the respective substrate main bodies 371 but are formed on the mother substrate 130 from which the plurality of substrate main bodies 371 are cut out. The mother substrate 130 is a disk-shaped plate made of ceramics as a forming material of the substrate main body 371 . The correction electrodes 377 are provided on the surface of the mother substrate 130 outside of the regions serving as the respective substrate main bodies 371 . The correction electrodes 377 are formed together with the respective electrodes in the step of forming the respective electrodes of the resistance circuits 370 a on the respective substrate main bodies 371 . In addition, the resistance circuit 370a of the third embodiment is derived from Figure 4 In the resistance circuit 270a of the second embodiment shown, the removed portion 272c and the correction electrode 277 are omitted.

[0069] based on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com