Breathable insole with composite interlayers

A technology of interlayer and insole, applied in insoles, footwear, clothing, etc., can solve problems such as sweating, odor, and poor comfort of the feet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

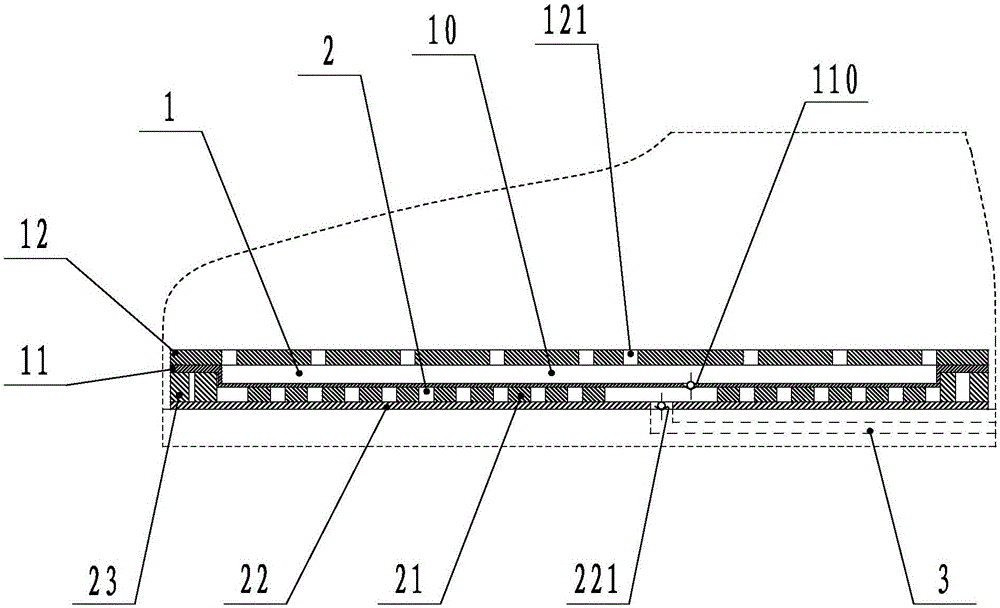

[0033] Example 1: refer to Figure 1 to Figure 5 , Figures 9 to 10 , in the above-mentioned embodiment, the air guide interlayer 1 can have various structural forms, and this embodiment is one of the preferred embodiments: the air guide interlayer 1 includes an air guide plate 11, and the upper end of the air guide plate 11 is connected with an airtight insole surface 12. The insole surface 12 is located at the uppermost end of the insole and is in contact with the bottom of the user's foot. The air guide plate 11 is provided with a concave air guide groove, and the air guide groove is provided with a main air groove 111 and a plurality of branch air guide grooves 112 connected with it. . The air guide grooves play the role of guiding the air, and the air can flow along the air guide grooves to various parts of the sole of the foot corresponding to the insole surface 12 . The bottom of the air guide groove is provided with an air guide plate ventilation port. The air guide ...

Embodiment 2

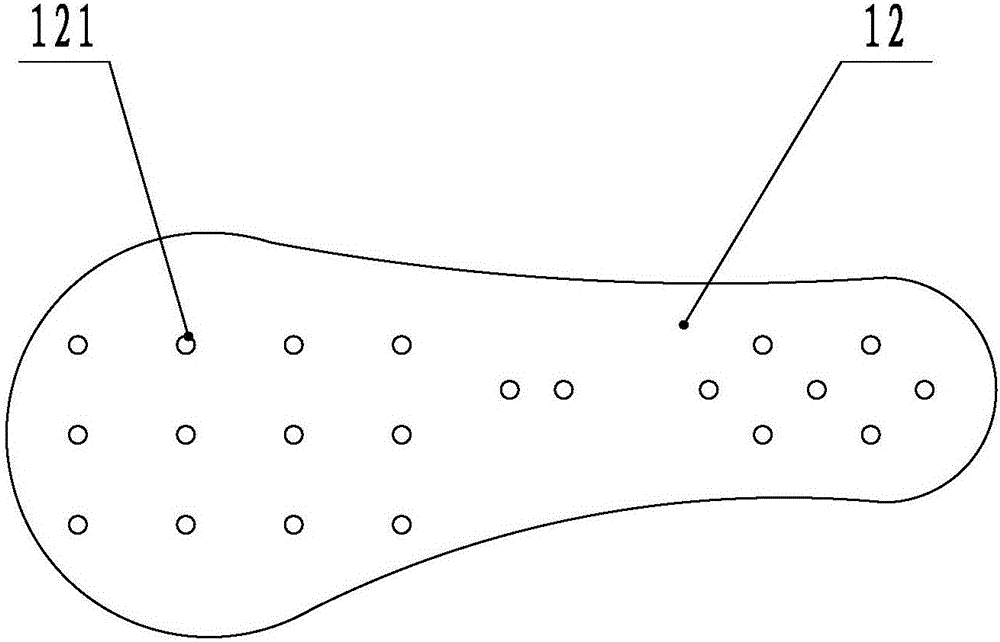

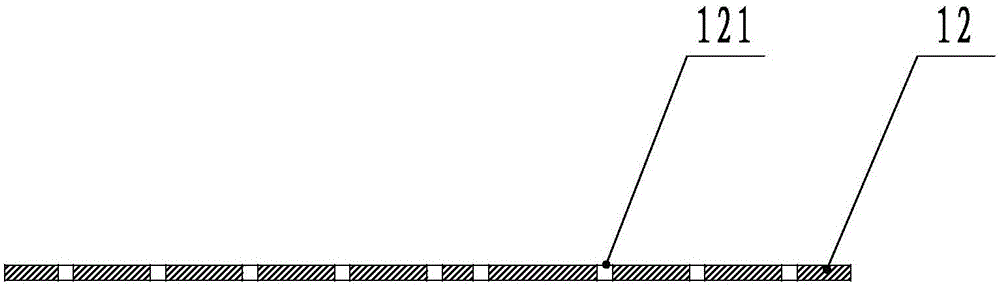

[0035] Embodiment 2: refer to Figure 2 to Figure 3 , Figures 11 to 14 , the present invention also provides another embodiment of the air guide interlayer. In this embodiment, the air guide interlayer 2 includes an air guide plate 11, the upper end of the air guide plate 11 is connected with an upper backing plate 13, and the upper end of the upper backing plate 13 is connected with a ventilation The insole surface 12, the air guide plate 11 and the upper backing plate 13 are connected with a number of supporting columns 113 with gaps between each other, the gap between the supporting columns 113 forms the air guiding channel 10, and the upper backing plate 13 corresponds to the air guiding A number of small ventilation holes 121 are provided at the position of the channel 10 . The second ventilation port 110 is arranged on the air guide plate 11 , and the second ventilation port 110 is preferably arranged at the front end of the air guide plate 11 , so that after the air e...

Embodiment 3

[0037] Embodiment 3: Referring to Embodiment 1 and Embodiment 2, the first ventilation port 221 and the second ventilation port 110 are not provided with a one-way valve, and the ventilation holes 121 are provided at the position of the insole surface 12 corresponding to the arch of the foot. The ventilation holes 121 are not pressed by the sole seal, and the air flows in and out between the inner cavity of the shoe and the insole from the ventilation holes 121, and the resistance received is small. When the compressed interlayer 2 in the insole is compressed and stretched, the air can flow in and out of the insole from the ventilation holes 121 and the first ventilation port 221, and complete a part of the air exchange in the insole space, so as to achieve the air exchange between the inner cavity of the shoe and the outside of the shoe. the goal of.

[0038] In the above embodiment, the connection between the upper backing plate 13 and the air guide plate 11 can be done in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com