Installing structure of bread maker stirring rod

A technology of installation structure and stirring rod, which is applied in the field of installation structure of bread machine stirring rod, can solve the problems of falling of metal chips such as aluminum chips, food contamination, etc., and achieve the effect of avoiding metal chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

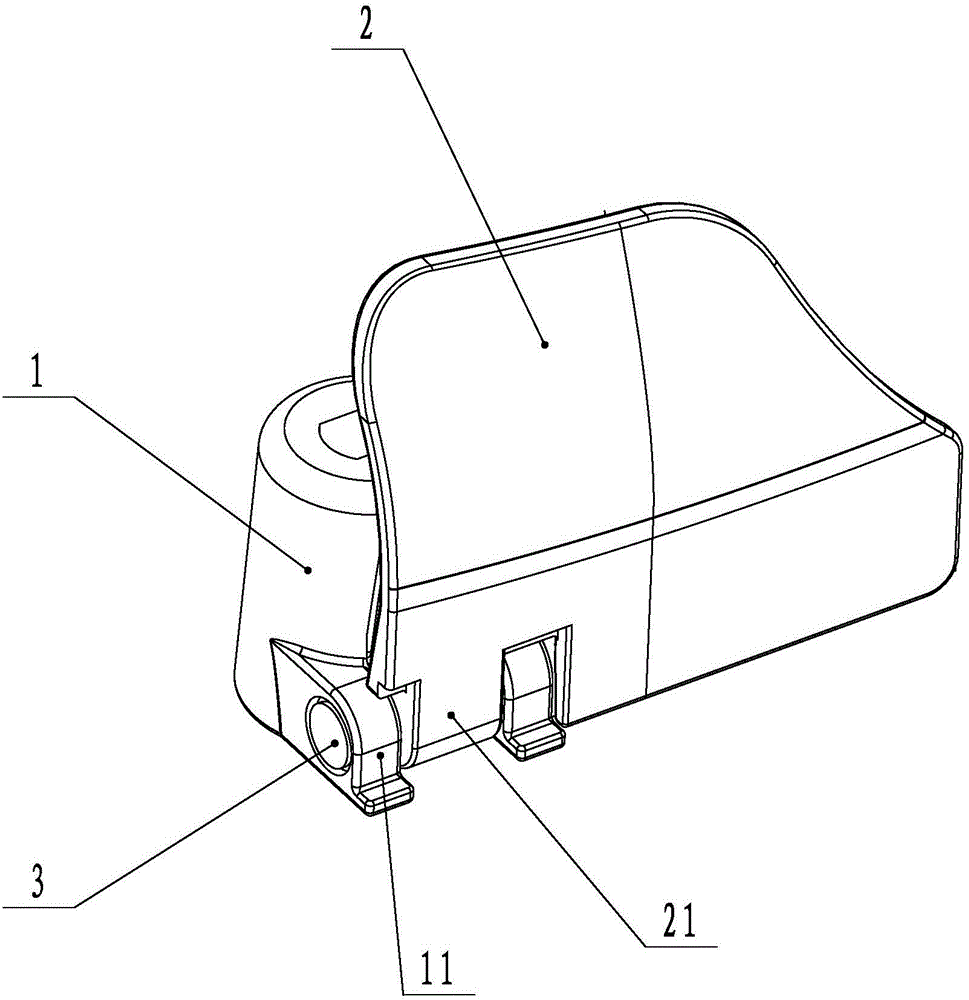

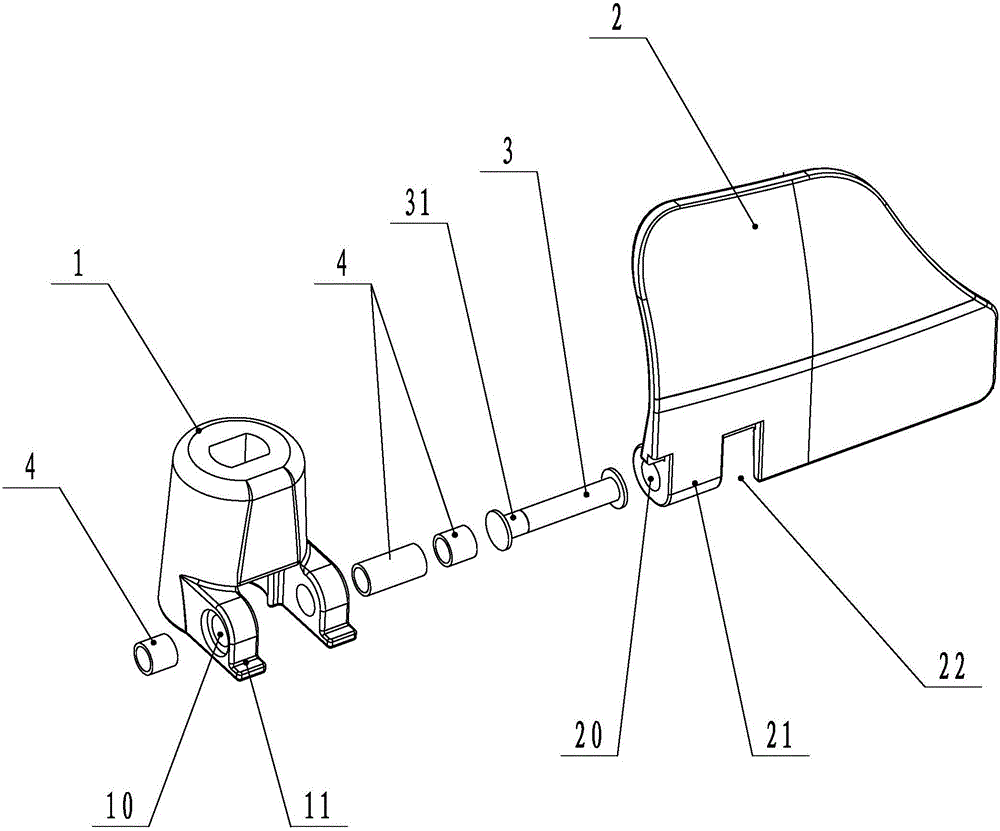

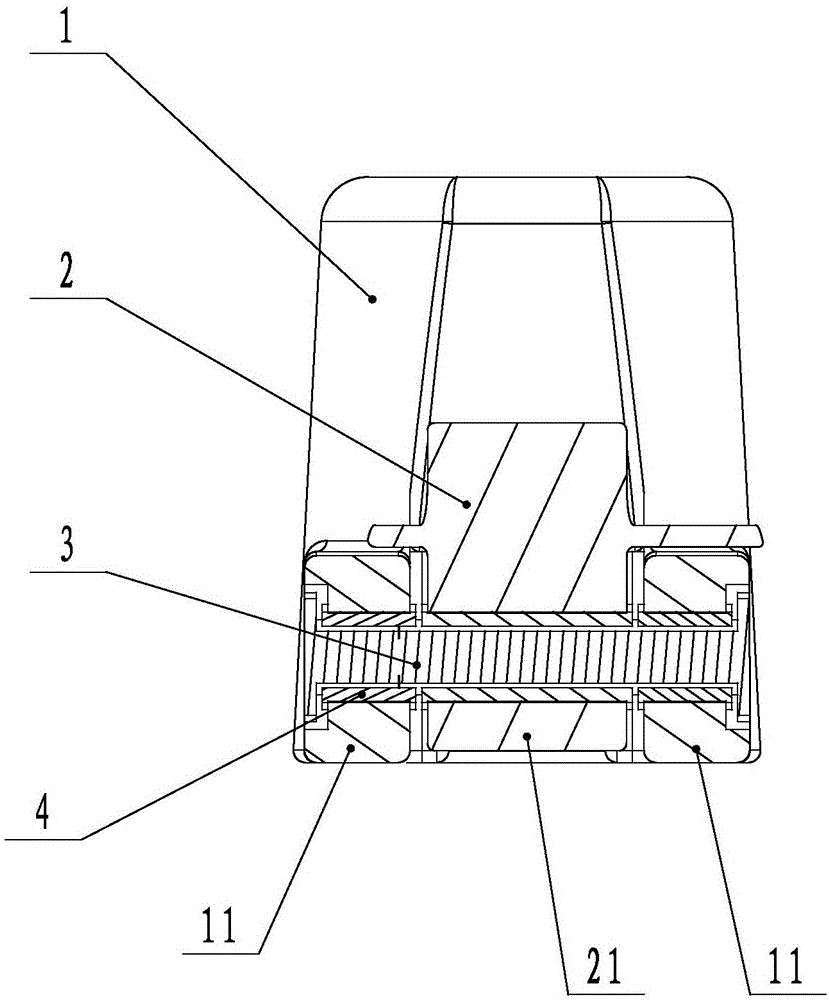

[0017] refer to Figures 1 to 3 , the installation structure of a stirring rod of a bread machine of the present invention comprises a rotating base 1 and a stirring rod 2, the rotating base 1 and the stirring rod 2 are usually made of cast aluminum, and the bottom side of the rotating base 1 is provided with a connecting hole 10, and the stirring The bottom of the rod 2 is provided with a corresponding matching hole 20 , and the stirring rod 2 is rotatably connected to the rotating base 1 through the pin shaft 3 passing through the fitting hole 20 and the connection hole 10 , and the outer end of the pin shaft 3 is sleeved with a sleeve 4 . In the present invention, the shaft sleeve 4 is sleeved on the outer end of the pin shaft 3, so that when the pin shaft 3 is rotatably connected in the connection hole 10 and the matching hole 20, it will not come into contact with the rotating seat 1 and the stirring rod 2, thereby avoiding wear and tear The metal shavings produced make t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com