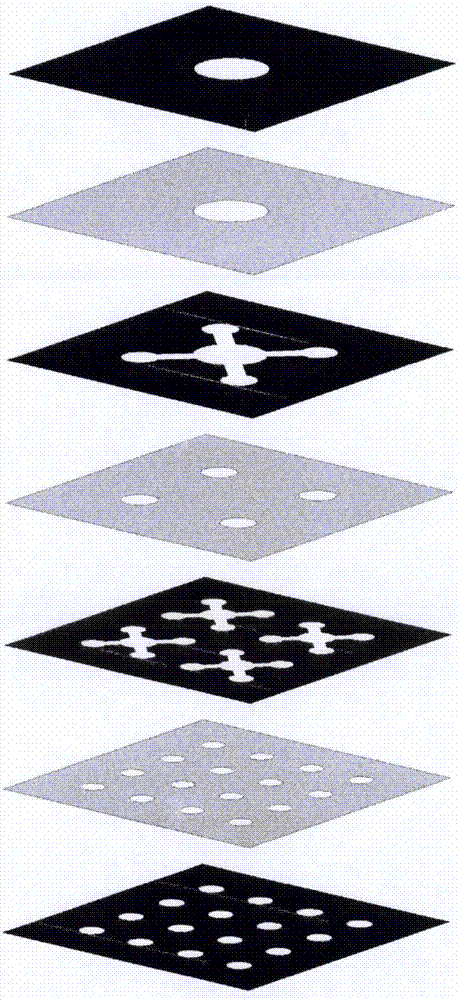

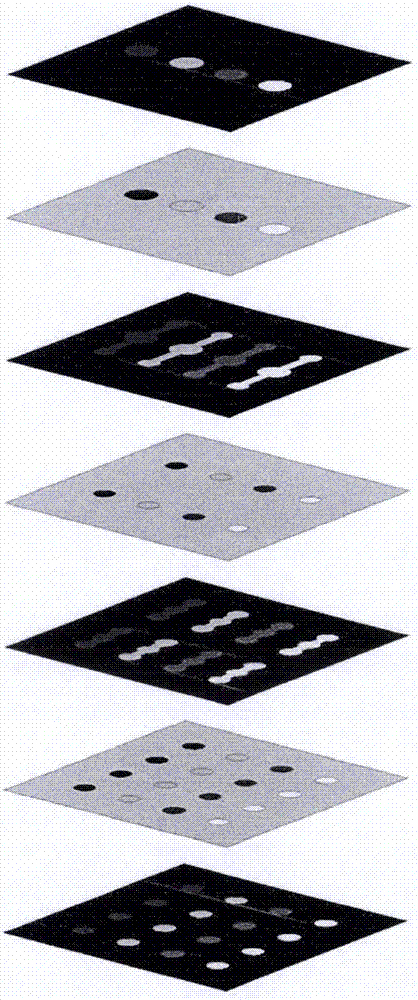

Preparation method of three-dimensional paper chip based on multi-plate patterned screen combined printing technology

A printing technology, screen printing technology, applied in the direction of chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problems of complex production process, high cost, low precision, etc., and achieve simple equipment and improved The effect of precision and simplification of production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Select a 300-mesh patterned ink screen, which is made of nylon and has a screen tension of 18N / cm. Use the patterned ink screen to print a hydrophobic ink with a volume ratio of 3:1 and ethyl acetate. Liquid, printed on the filter paper, the screen distance between the printing ink screen and the filter paper during printing is 1.5mm, the angle when the scraper contacts the printing ink screen is 45°, the printing speed is 0.2m / s, the paper Under a pressure of 12N, the channel layer and detection layer of the paper chip (2D paper chip) were obtained.

[0040] The pretreatment agent adopts a chemical masking agent, which is specifically 20% sodium malonate and 15% sodium fluoride in an aqueous solution. A mixed solution of EDTA and HF (EDTA: 0.05mol l -1 ; HF: 0.05mol l -1 ) configured as 1.0mg ml -1 The pH of the solution was adjusted to 8.5 with 2% (v / v) ammonia water to obtain the detection agent.

[0041] Select a 400-mesh patterned drug printing screen, which is...

Embodiment 2

[0045] Select a 400-mesh patterned ink screen, which is made of nylon and has a screen tension of 18N / cm. Using the patterned ink screen, the hydrophobic printing solution composed of acrylic pigment and ethanol with a volume ratio of 1:1 is used to print On the filter paper, the screen distance between the printing ink screen and the filter paper during printing is 1.5mm, the angle when the scraper contacts the printing ink screen is 45°, the printing speed is 0.2m / s, and the pressure of the paper is 12N, the channel layer and the detection layer of the paper chip (2D paper chip) were obtained.

[0046] The pretreatment agent uses a chemical masking agent, specifically Na 2 S 2 o 3 (40ppm) and 0.05% (v / v) H 2 SO 4 mixed solution. Use 50% (v / v) acetone aqueous solution to prepare 2 mg ml of chromogen dimethylglyoxime -1 solution (the solution also contains EDTA: 0.05mol l -1 , Na 2 S 2 o 3 : 0.05mol l -1 ) to obtain the detection agent.

[0047] Select a 400-mesh p...

Embodiment 3

[0051] Select a 200-mesh patterned ink screen, which is made of nylon and has a screen tension of 15N / cm. Using the patterned ink screen, a hydrophobic printing solution composed of paraffin wax and n-heptane with a mass ratio of 1:150 is used to print On the cellulose acetate film, the screen distance between the printing ink screen and the cellulose acetate film during printing is 1.8mm, the angle is 40° when the scraper contacts the printing ink screen, and the printing speed is 0.6m / s, the cellulose acetate membrane was subjected to a pressure of 4N to obtain the channel layer and detection layer of the paper chip (2D paper chip).

[0052] The pretreatment agent is ammonia water with a volume fraction of 2%, and the detection agent is dimethylglyoxime with a concentration of 2 mg / ml.

[0053] Select a 300-mesh patterned drug printing screen, which is made of nylon, and the screen tension is 15N / cm; use the patterned drug printing screen to print the above pretreatment age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com