Mineral dry method vibration sorting device and method

A sorting device and vibration direction technology, applied in chemical instruments and methods, solid separation, separating solids from solids with airflow, etc., can solve problems such as low precision, difficulty in removing medium gangue, poor stability, etc., and achieve The effects of high sorting accuracy, shortened sorting time, and increased motion displacement difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

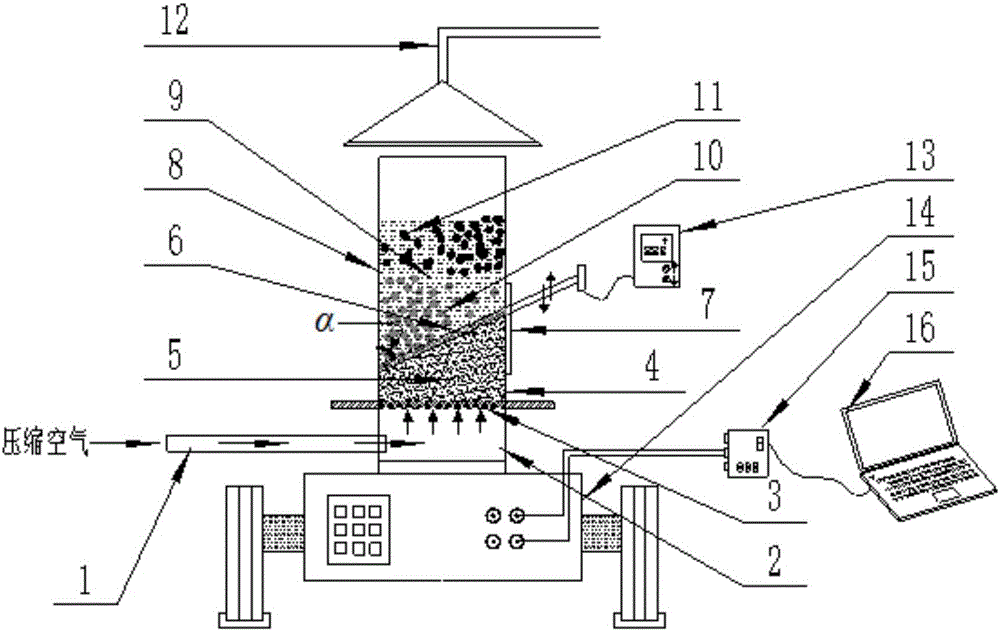

[0027] This embodiment provides a mineral dry vibration separation device, the device includes a separation chamber 8, such as figure 1 As shown, a sorting weight 9 is arranged in the sorting chamber 8; an air distribution chamber is arranged at the bottom of the sorting chamber 8, and the air distribution chamber has an air inlet 1, and compressed air enters the air distribution chamber from the air inlet 1, and the The air flow is evenly distributed, and then enters the sorting chamber 8, where the air flow and the sorting weight 9 are evenly mixed in the sorting chamber 8 to form a fluidized environment. Vibrating the sorting chamber 8, in the fluidized environment of the sorting chamber 8, layered separation is carried out according to the density difference, the particles with higher density sink to the bottom of the sorting chamber 8, and the particles with lower density float on the bottom of the sorting chamber 8 The upper part, so as to achieve the sorting of minerals...

Embodiment 2

[0033] This embodiment provides a dry vibration separation method for minerals, using the above separation device, taking the separation of 1-3mm fine-grained low-grade hematite ore as an example.

[0034] According to the separation density requirements of 1-3mm fine-grained low-grade hematite ore, the particle size range is 75-150μm, and the true density is 7.8g / cm 3 The gas-atomized iron powder is used as the leading weight, and the zircon sand of 150-250 μm is used as the auxiliary weight. After the two are mixed, they are placed in the sorting chamber 8 as the sorting weight 9, wherein the addition of the zircon sand cannot More than 20% of the whole sorting weight quality; according to the selected sorting weight type, particle size range and density and the sorted mineral type, particle size range and density, etc., the addition of sorting weight 9 is preferably formed The height of the static bed layer is 1 / 3~1 / 2 of the height of the sorting chamber; then, fine-grained...

Embodiment 3

[0036] Taking the separation of 1-6mm fine-grained coal as an example, according to the separation density requirements, magnetite powder is used as the main weighting material, and coal powder with a particle size of less than 1mm is the auxiliary weighting material, and the auxiliary weighting matter of coal powder can be added in advance Magnetite dominates the weight, and secondary coal powder less than 1mm can also be used as auxiliary weight in the separation process, and the amount of auxiliary weight coal powder added cannot exceed 15% of the entire separation weight; the magnetic The iron ore powder is 0.074-0.3mm wide-grained magnetite powder, of which the 0.15-0.3mm particle size accounts for 50%, and the true density is 4.5g / cm 3 , the bulk density is 2.65g / cm 3 , the height of the static bed formed after adding the sorting weight is 1 / 3 of the height of the sorting chamber. The fine-grained medium adopts fine-grained magnetite powder, and the filling volume is 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com