Machining process of injection molding machine frame

An injection molding machine and machining technology, which is applied in the field of machining technology of injection molding machine frames, can solve the problems of long hoisting and turning time of large frames, long processing cycle, appearance damage, etc., so as to facilitate repair and maintenance work, automatic Good lock performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

[0026] The machining process of the injection molding machine frame includes the use of five-sided gantry milling to process the main bearing surface and side surfaces, the bottom surface is positioned by the first process, and the bottom surface is processed by the second process. The specific steps are as follows:

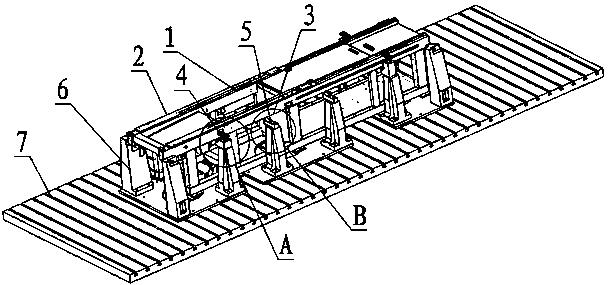

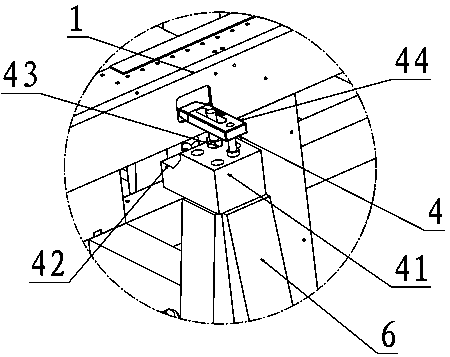

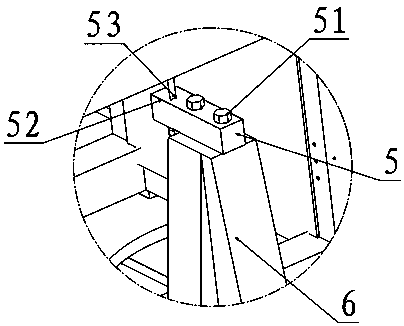

[0027] The first step is to fix the frame on the fixture, and use five-sided gantry milling to process the main support surface 2 and four sides 3 of the frame 1, and design dimensions for a total of five surfaces;

[0028] The second step is to adjust the height of the frame on the fixture to achieve positioning. The fixture is provided with several screw clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com