Efficient roller type polisher for wood surfaces

A wood surface, drum-type technology, applied in the direction of grinding frames, machine tools suitable for grinding workpiece planes, grinding machines, etc., can solve the problems of environmental pollution, low grinding efficiency, low degree of automation, etc. Easy to fix, efficient automatic grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

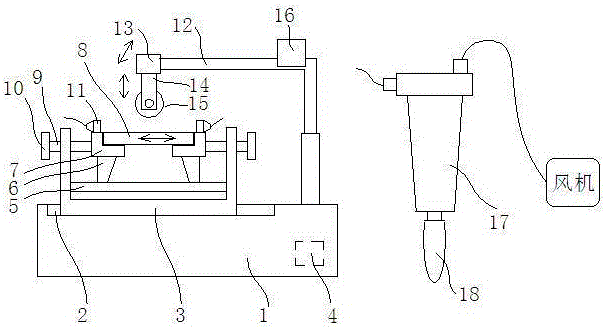

[0014] Accompanying drawing is a kind of specific embodiment of the present invention.

[0015] like figure 1 As shown in , this embodiment includes a base 1, on which a transverse slide rail 2 is provided, on which a transverse carriage 3 is slidably connected, and a drive motor 4 for driving the transverse carriage to move along the transverse slide rail is provided in the base , the horizontal sliding frame is provided with a horizontal sliding rail Ⅰ 5, two horizontal sliding seats 6 are slidably connected to the horizontal sliding rail Ⅰ, and the upper ends of the two horizontal sliding seats are respectively fixed with oppositely arranged "L" shaped wood fixing cards 7, and the two wooden Timber 8 to be polished can be fixed between the fixed cards, and threaded adjustment bolts 9 are installed on the outsides of the two wood fixed cards. The horizontal sliding frame is threaded to adjust the position of the wood fixed on the horizontal slide rail Ⅰ, so as to realize th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com