Crator grinding equipment and crator grinding method

A welding scar and equipment technology, applied in the welding scar grinding equipment and welding scar grinding field, can solve the problems of low work efficiency, large physical consumption of welding scar grinding, and poor grinding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

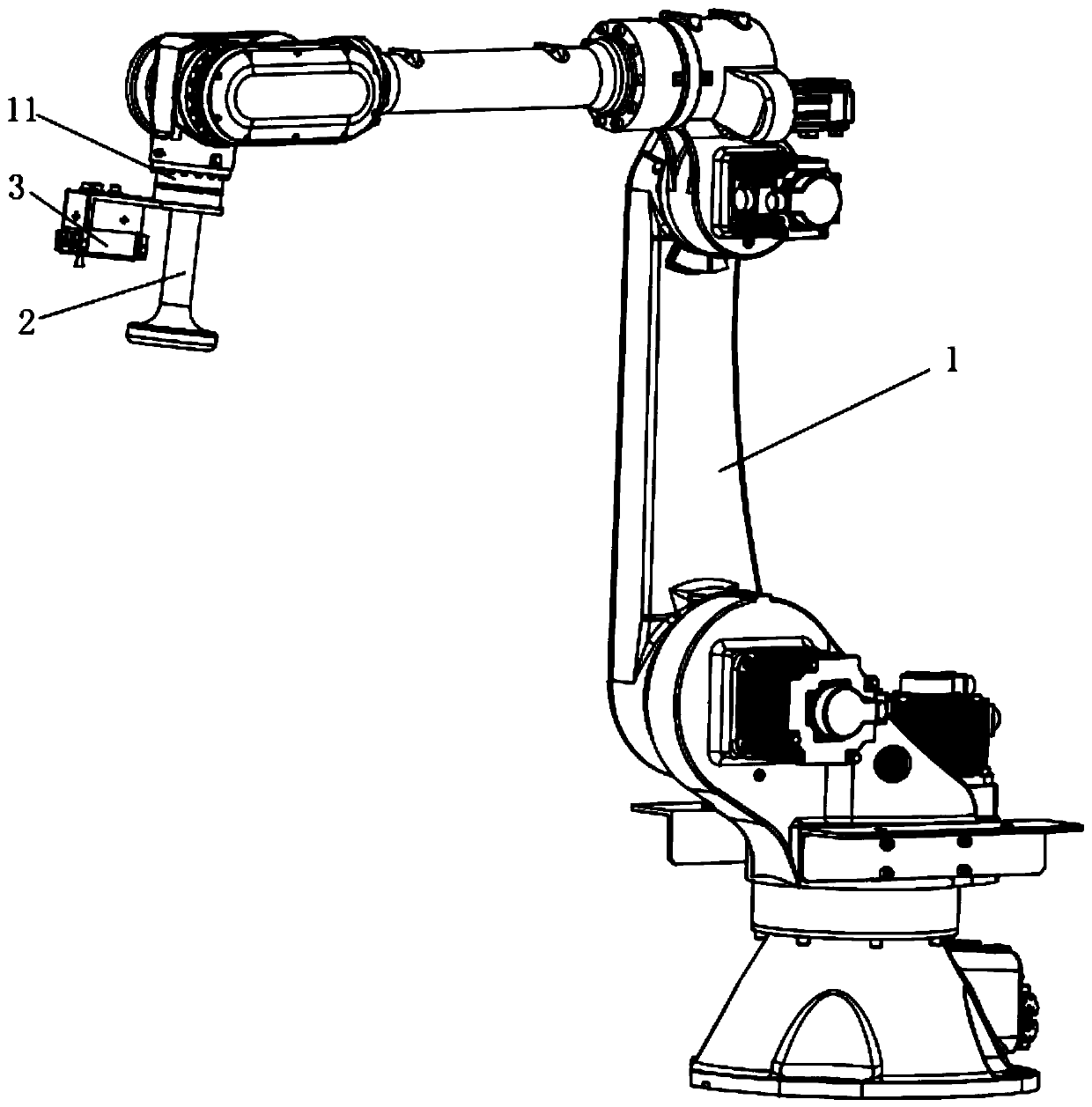

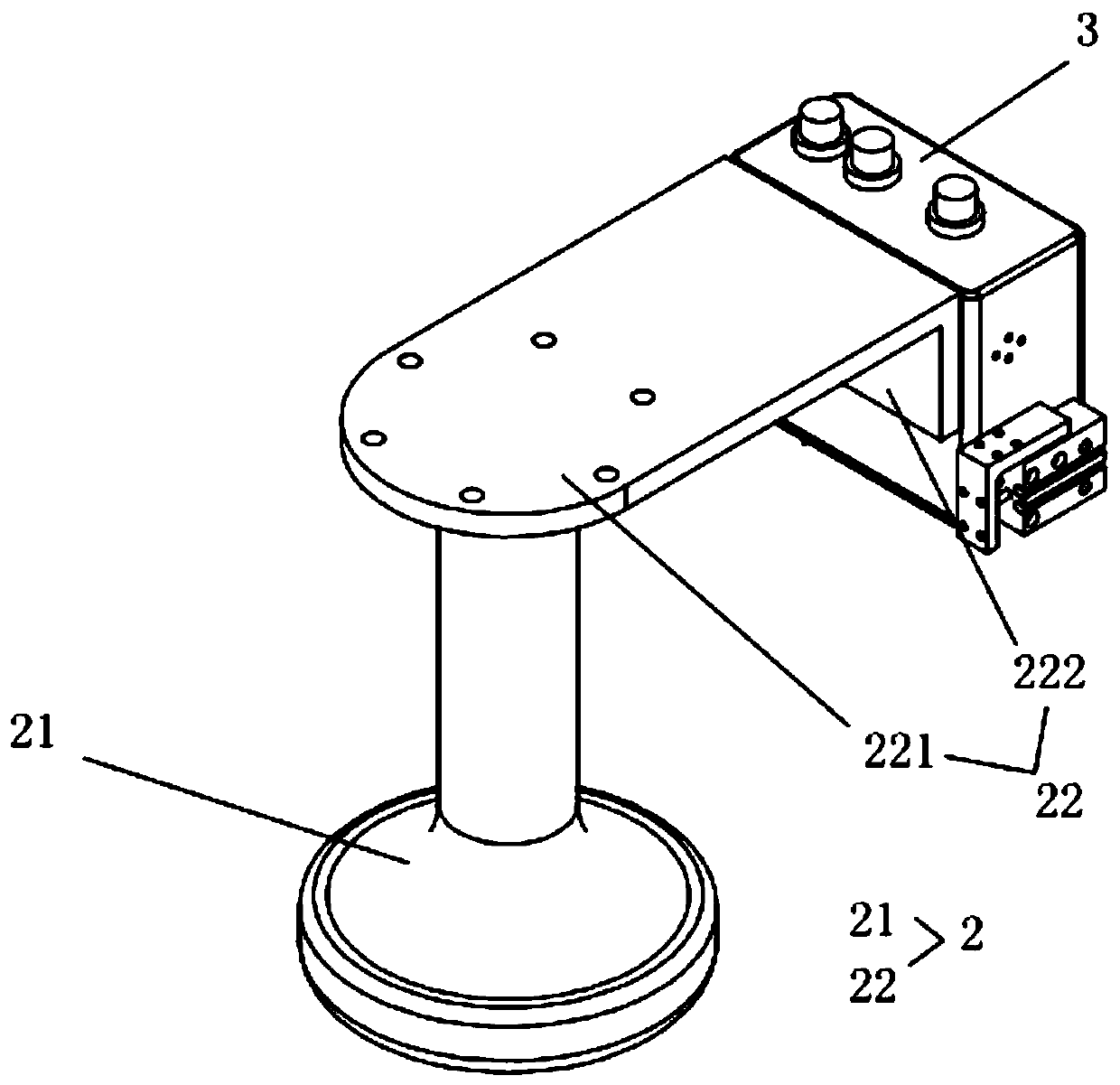

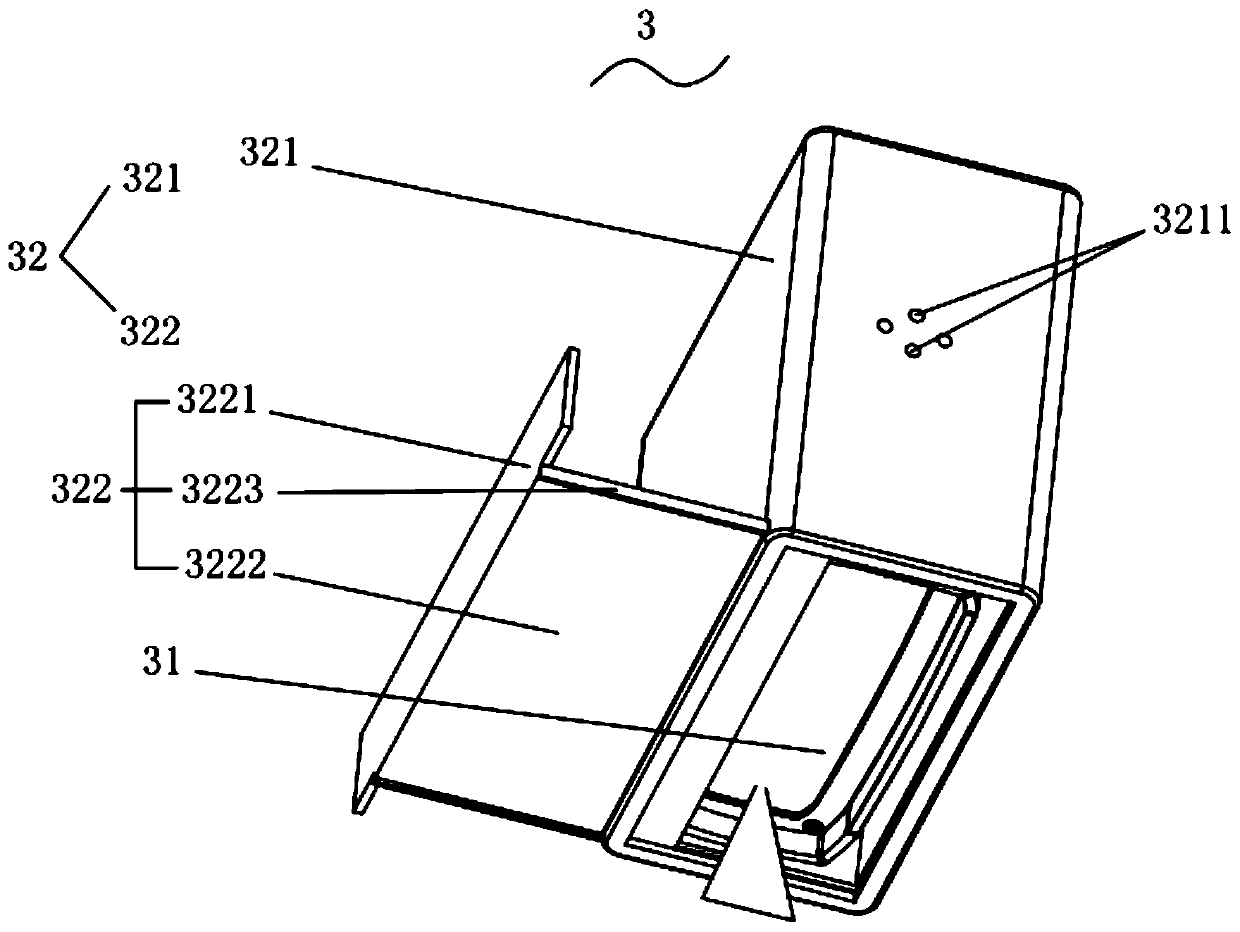

[0037] The traditional welding scar grinding is mainly through manually holding the grinding machine, and the grinding track of the grinding head of the grinding machine is controlled by hand to achieve the purpose of grinding the welding scar. During the grinding process, workers will grind while observing, and it often takes multiple grinding and observations to make the weld scars meet the requirements of regularity. However, manual grinding consumes a lot of energy and produces a lot of dust, which makes the working environment harsh. In addition, the effect of manual grinding largely depends on the skills and experience of the operators. The track depth of welding scar grinding is unstable, and the grinding efficiency is low, which is not conducive to quality control and work efficiency improvement. At present, there are automatic grinding devices / systems that use robots and vision guidance in the existing methods to replace manual work. Generally, vision is used to guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com