Anti-static worktable

A workbench, anti-static technology, used in workbenches, manufacturing tools, metal processing equipment and other directions, can solve the problems of bulky constant temperature welding table, many special disassembly tools, inconvenient to carry, etc., to achieve anti-static constant temperature welding, overcome inconvenience Portable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with the embodiments.

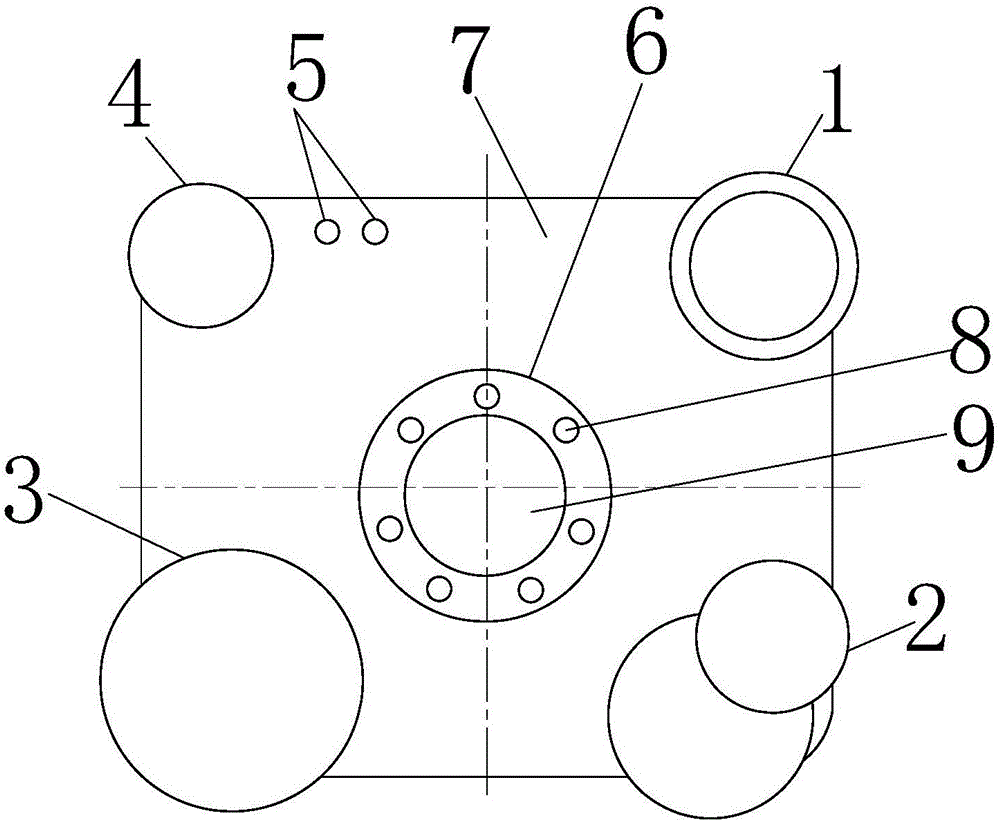

[0011] Such as figure 1 As shown, an antistatic workbench includes a mounting frame 7, the middle part of the mounting frame 7 is a boss 6, and the periphery of the upper end surface of the boss 6 is evenly provided with several grooves for placing screwdriver heads 8. A screwdriver groove 9 for placing the screwdriver handle is provided in the center of the upper end surface of the boss 6; a cylindrical magnet 1 for absorbing the screwdriver is installed on the right rear corner of the mounting frame 7, and the right front corner of the mounting frame 7 Two adjacent circular boxes 2 are installed for placing rosin and solder wire, a constant temperature electric soldering iron fixing frame 4 is installed in the left rear corner of the mounting f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com