Plastic bottle compression mechanism

A technology of compression mechanism and plastic bottle, applied in the direction of presses, manufacturing tools, etc., can solve the problems of easy rebound, thick material, and rebound, and achieve the effect of not easy to rebound, avoid liquid splashing, and reduce driving force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

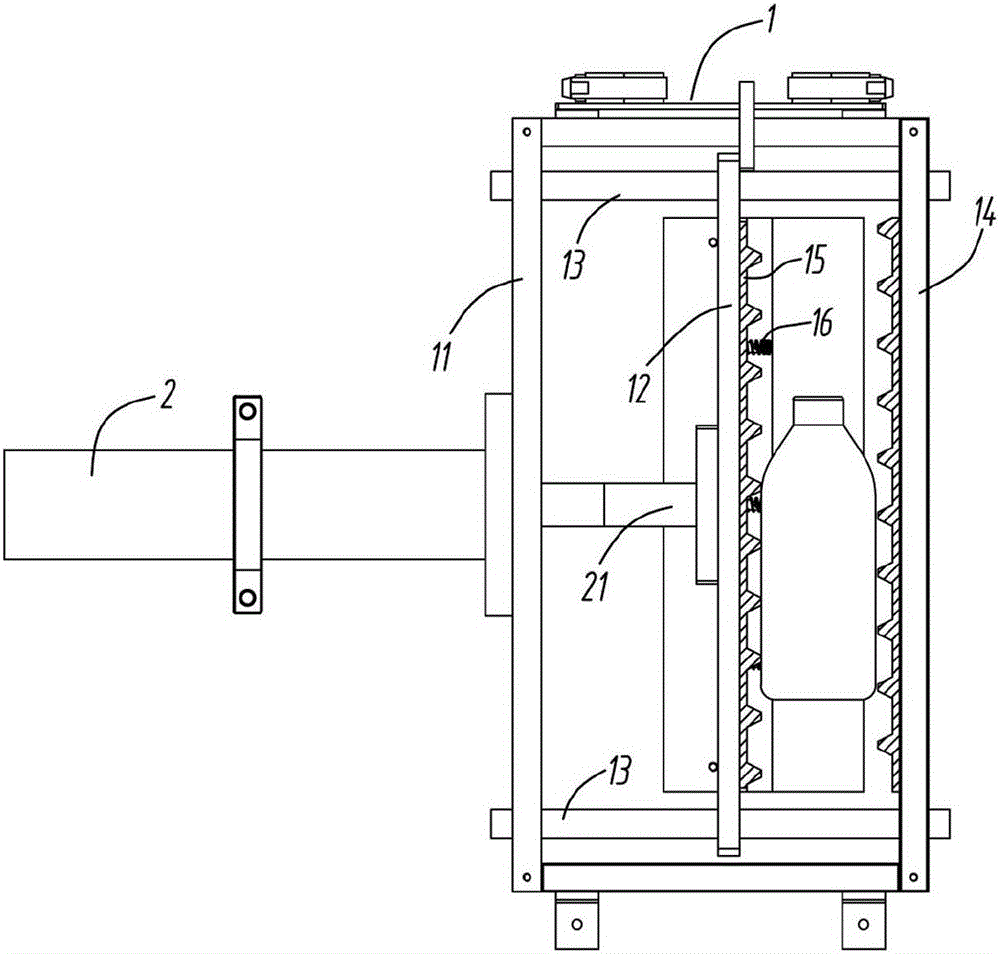

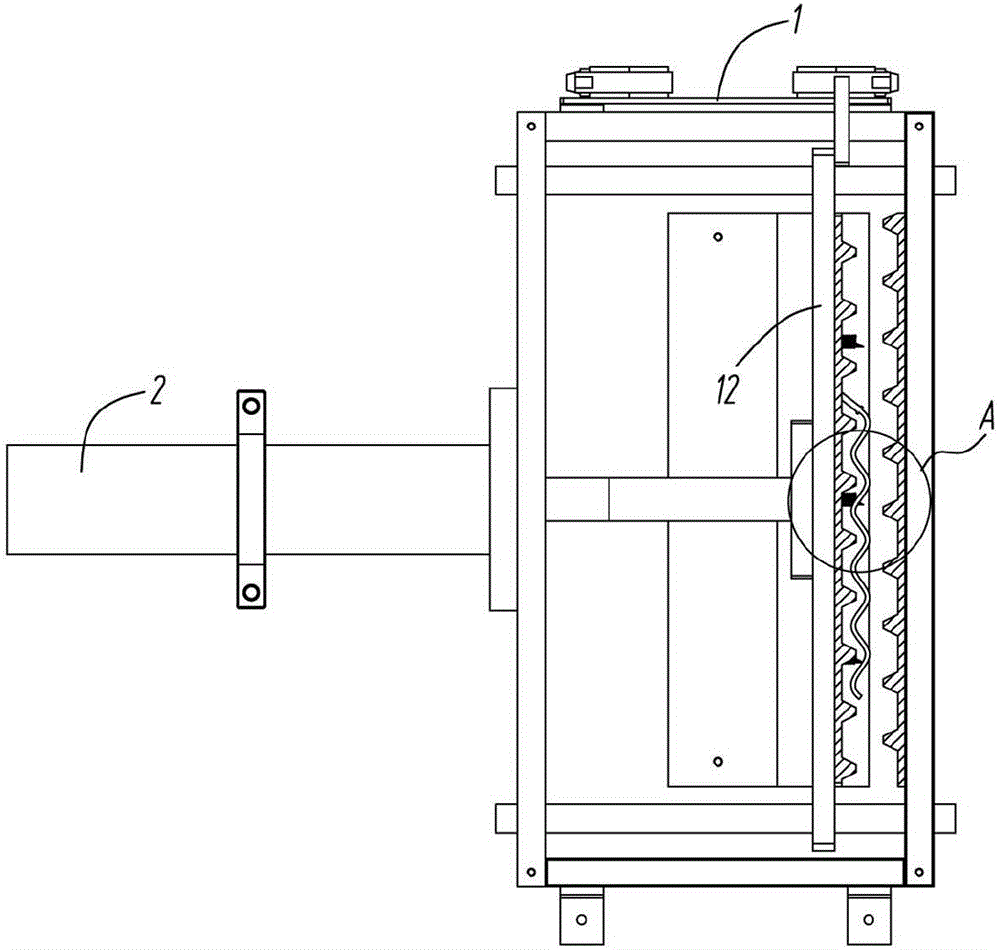

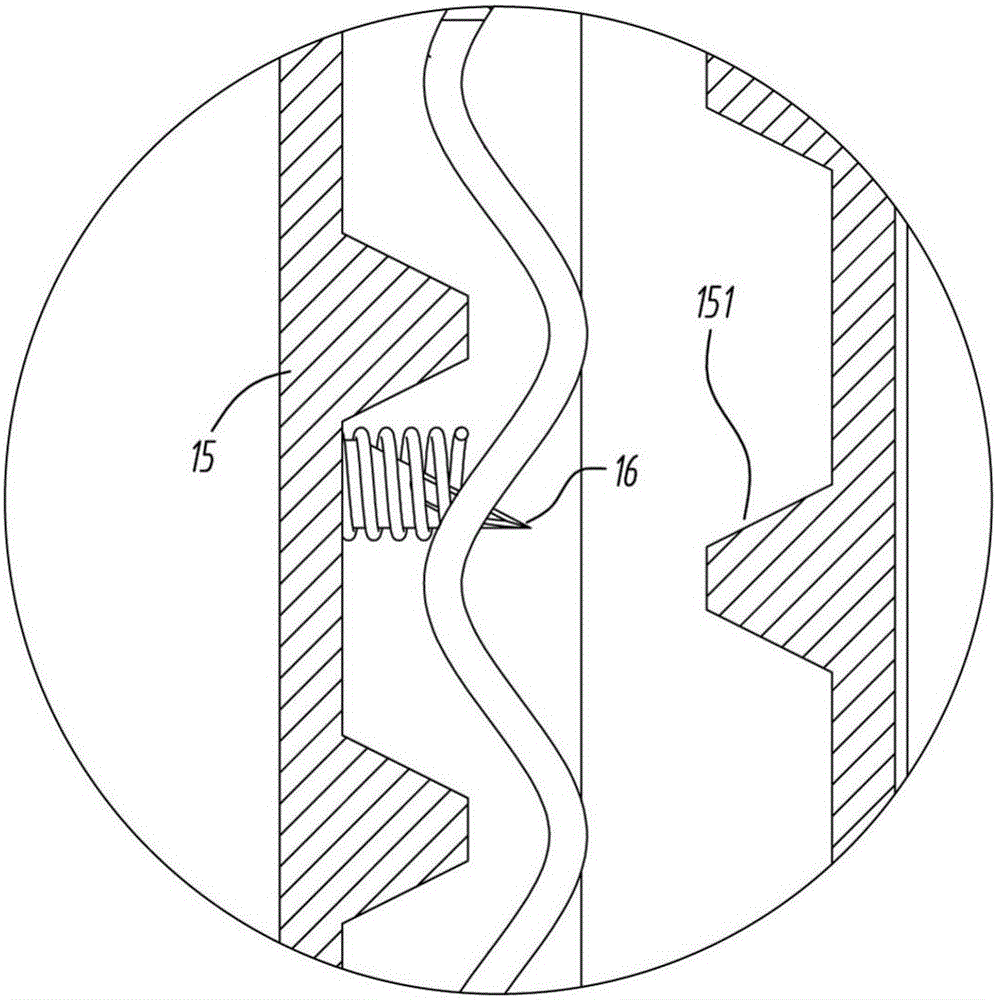

[0020] refer to Figure 1 to Figure 6 The plastic bottle compression mechanism shown includes a compression box 1, and the movable plate 12 parallel to the rear side plate 11 is arranged inside the compressed box 1, and the movable plate 12 can be driven by the hydraulic cylinder 2 to be relatively The rear side plate 11 is translated back and forth, the hydraulic cylinder 2 is fixed on the rear side plate 11 and the movable end 21 passes through the rear side plate 11 and is fixed to the movable plate 12 . The movable plate 12 is pierced with a number of guide posts 13 to keep its translation stability, and the guide posts 13 include four guide posts fixed between the front side plate 14 and the rear side plate 11 and evenly distributed at the four corners. . A rack plate 15 is provided on the inner wall between the movable plate 12 and the front side plate 14 of the compression box 1, and the rack plate 15 has vertical racks 151 evenly distributed. The cross section of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com