Fill roadbed structure and construction method thereof

A technology of roadbed and stonework, applied in infrastructure engineering, botanical equipment and methods, roads, etc., can solve the problems of high protection cost of filling roadbed, high cost of spoil yard, and large accident loss, etc., to reduce soil erosion , reduce the cost of protection, and reduce the effect of harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

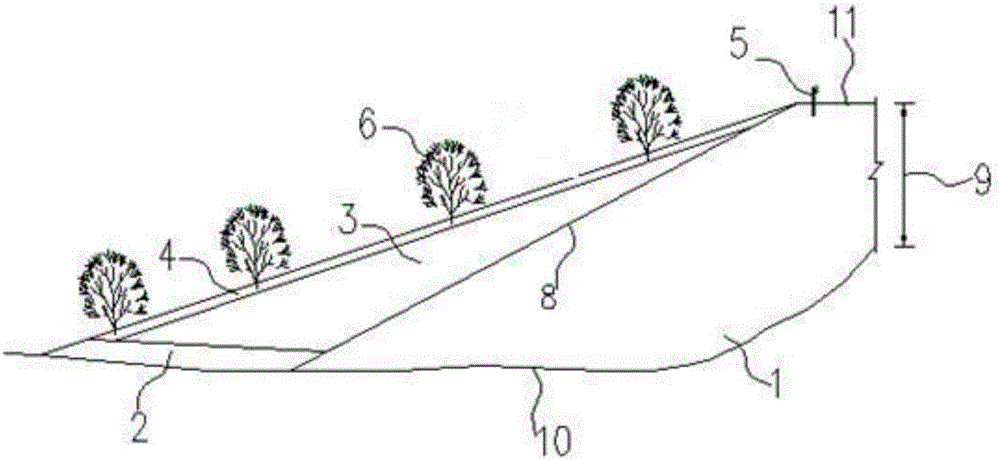

[0023] Refer to attached figure 1 , the present embodiment provides a filling roadbed structure, including a roadbed 1, the bottom of the side slope of the roadbed 1 is laid with a stone cushion 2, and the stone cushion 2 and the side slope of the roadbed 1 are filled with earth-rock mixed filling 3 In order to form a filling slope, the slope ratio of the filling slope is less than or equal to 1:4.0, and the outer side of the subgrade is filled with stone cushion and earth-rock mixed filling to form a protection system to protect the conventional subgrade and serve as the foundation of the slope soil. The slope top of the subgrade 1 is provided with a guardrail 5, and the earth-rock mixed filling 3 is covered with slope soil 4, and trees 6 are planted on the slope soil 4. 3 is the spoil produced by the excavation section, and the slope soil 4 comes from the surface of the roadbed, and no additional soil is needed.

[0024] The construction method is as follows:

[0025] Firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com