A large-span multifunctional robotic engineering construction equipment

A kind of engineering construction and multi-functional technology, which is applied in infrastructure engineering, building maintenance, roads, etc., can solve problems such as inability to complete work requirements, and achieve the effects of high reliability, cost saving, and large working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

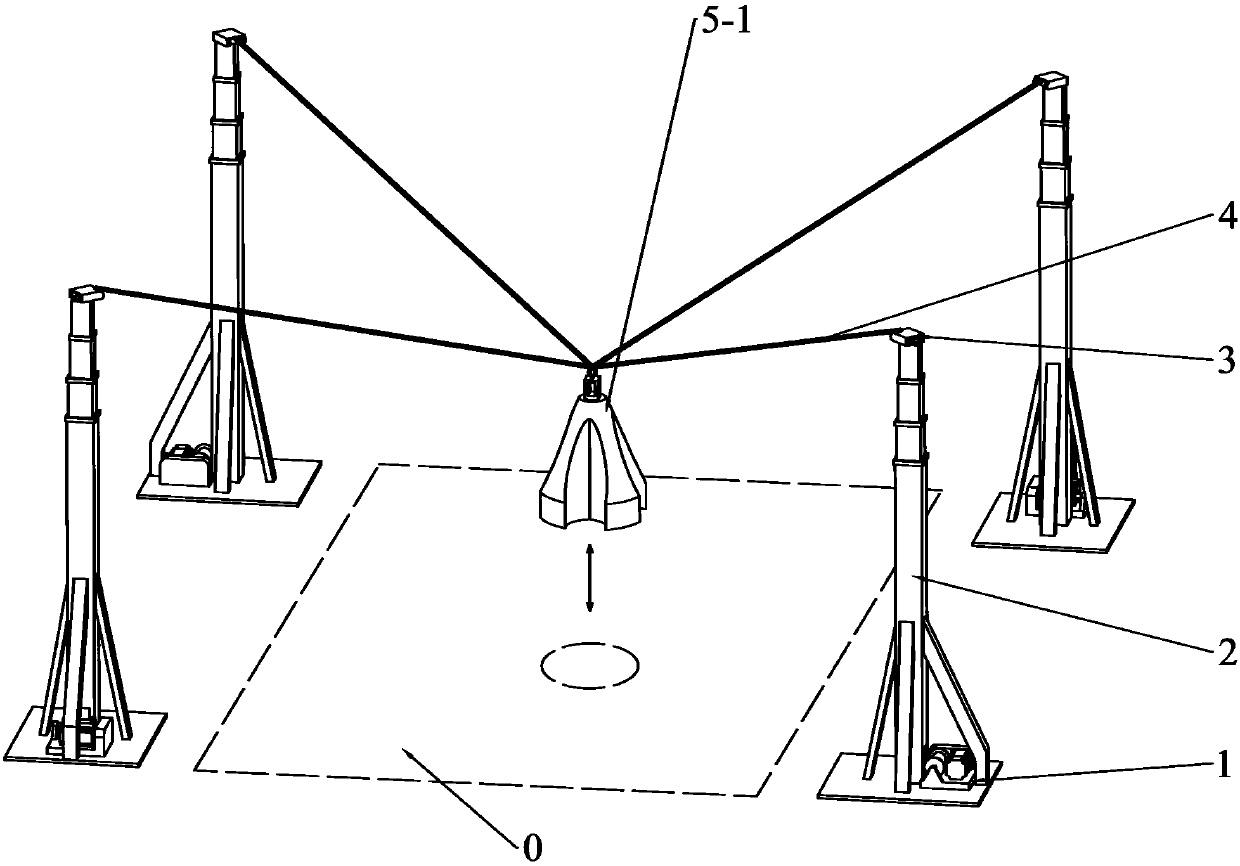

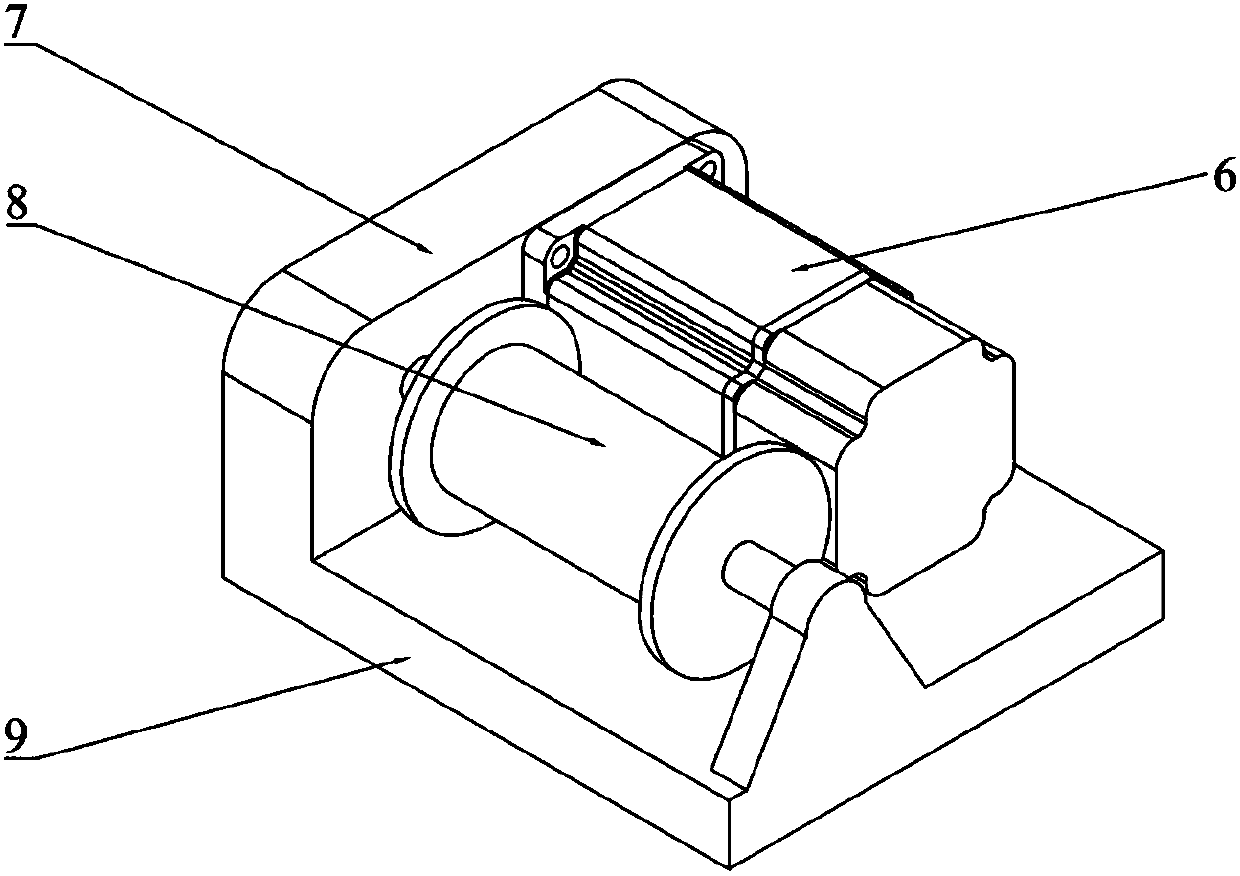

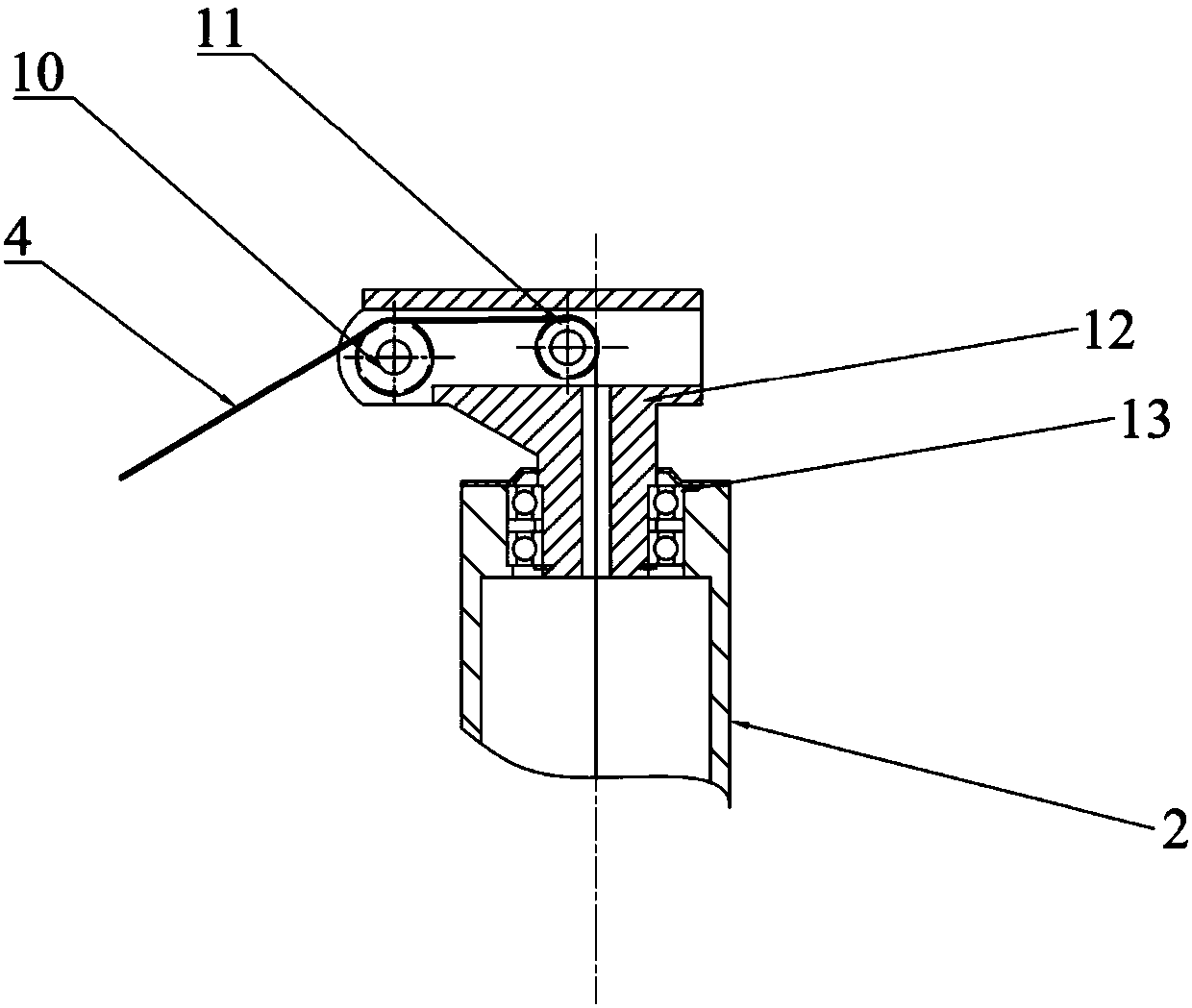

[0022] The structure of the large-span multi-functional robotized engineering construction equipment of the present invention is as follows when it is used for punching and piling figure 1 As shown, it includes four support columns 2, a wire rope drive unit 1, a wire rope guide device 3 and a wire rope 4, a controller, and a drop hammer (ie, the end effector of this embodiment) 5-1 provided with each support column; Among them, the four support columns 2 are distributed and arranged around the construction area 0 according to the requirements of the site conditions. In this embodiment, the bottom of the support columns 2 is provided with a base that plays a fixed role (the size and shape of the base should be determined according to the actual situation of the project) In order to further strengthen the support column 2, an inclined support beam can be provided on the outside; the inside of the support column 2 is provided with a hydraulic cylinder for realizing the lifting of ...

Embodiment 2

[0032] The structure of a kind of large-span multifunctional robotized engineering construction equipment of the present invention is used for road breaking is as follows: Figure 5 As shown, the main difference from Embodiment 1 is that the end effector adopts a cylindrical pavement breaker 5-2 according to engineering requirements, and the lower end of the hammer has an inclined cut surface at the front and rear respectively, and the two cut surfaces constitute the shovel surface 5-21; at the same time , the equipment also includes three pulling columns 15, and a wire rope drive unit 1, a wire rope guiding device 3 and a wire rope 4 that are matched with each pulling column; in the present embodiment, three supporting columns 2 are provided; wherein, three The supporting column 2 and the three pulling columns 15 are fixed in a circumferentially symmetrical staggered manner outside the construction area 0 according to the site conditions (the number of the supporting columns a...

Embodiment 3

[0035] The structure of a large-span multi-functional robotic engineering construction equipment of the present invention when used for wall demolition is as follows: Figure 7 As shown, the difference from Embodiment 1 is that the end effector adopts a pear-shaped iron ball structure 5-3 according to engineering requirements. When carrying out wall demolition, the controller controls the amount of rope output of the steel wire rope drive unit 1 to make the pear-shaped iron ball swing under the joint pull of four steel wire ropes 4 to realize the remote control of the pear-shaped iron ball 5-3. The operation of breaking and demolishing the wall is realized through the continuous impact of the pear-shaped iron ball 5-3 on the wall. The plurality of steel wire ropes in this embodiment jointly pull and swing the pear-shaped iron ball 5-3, which has a strong overall bearing capacity and high stability, and is safer and more reliable than the method of using a hoist to hang the iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com