A variable diameter sand control screen

A sand control screen, a variable technology, applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of packer sand burial, test string flow channel blockage, etc., to prevent blockage, test The effect of real data and effective technical support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

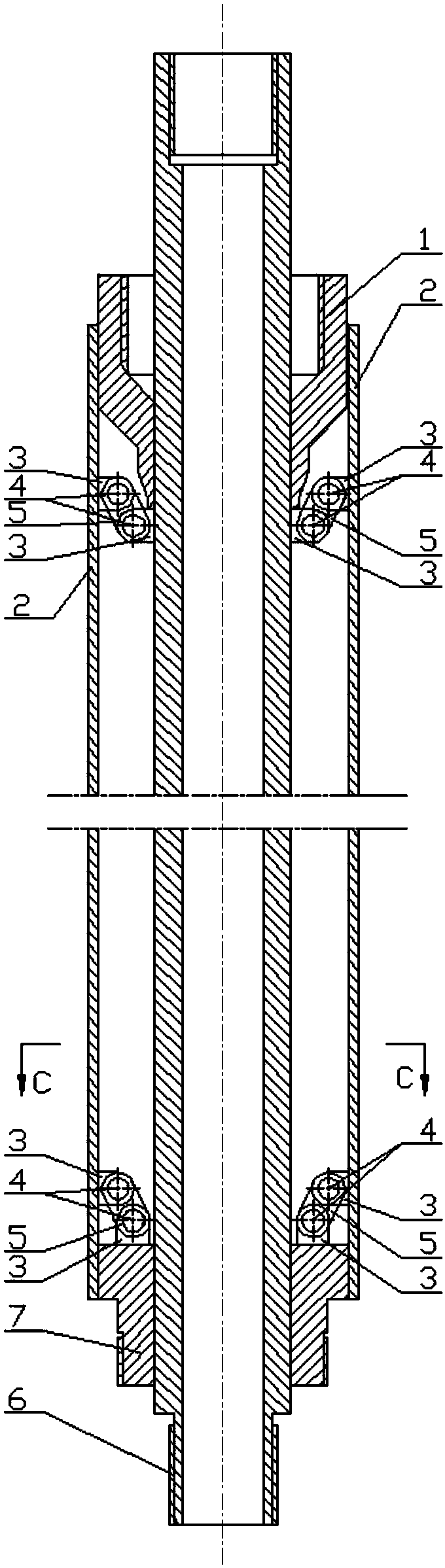

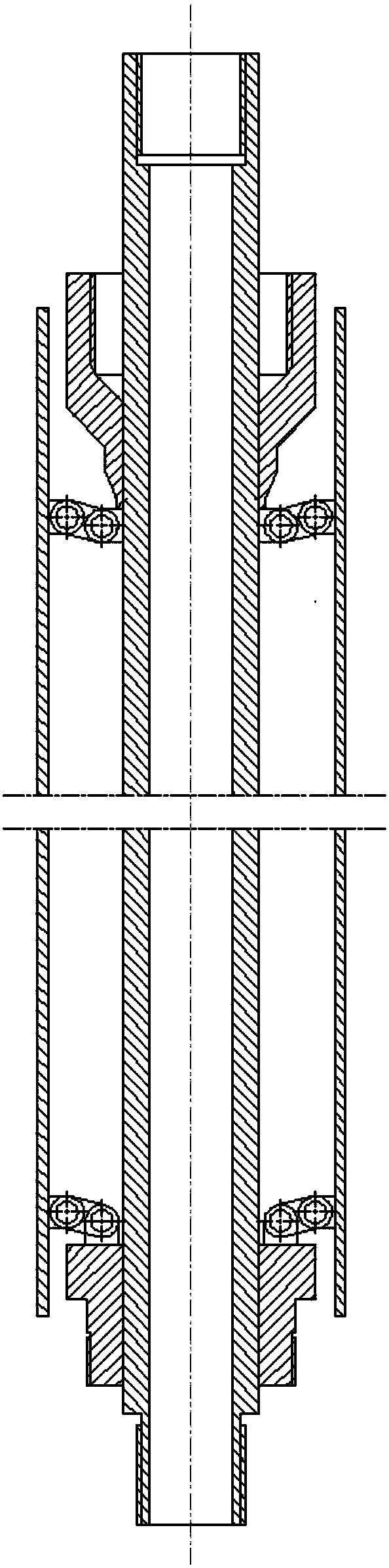

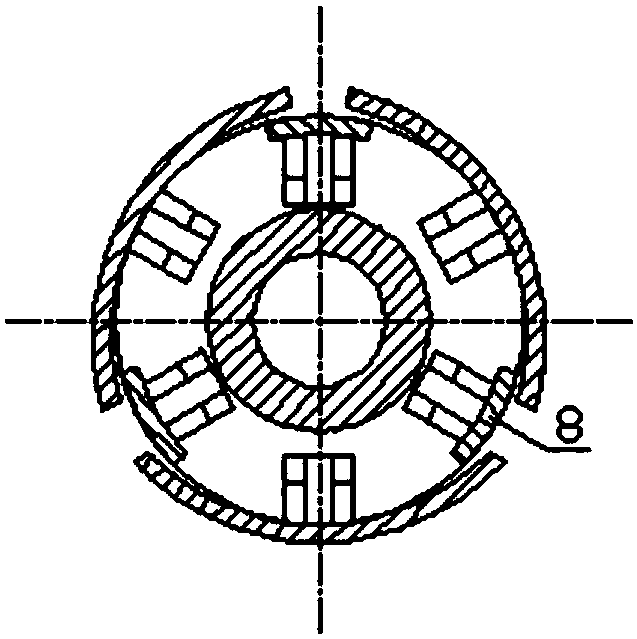

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0016] Such as Figure 1-3 As shown, the variable-diameter sand control screen of the present invention includes a mandrel 6 connected to the oil pipe, an upper joint 1 and a lower joint 7 respectively sleeved on the upper and lower ends of the mandrel 6 for connecting tools, and a split-type multi-piece sand control screen. The screen piece 2 and the sand-retaining steel plate 8 located between the two sand-control screen pieces 2, the split-type multi-piece sand-control screen piece 2 and the multi-piece sand-retaining steel plate 8 just form a full-circle outline, and the multi-piece sand control The screen piece 2 and multiple sand-retaining steel plates 8 are respectively connected to the upper joint 1 and the lower joint 7 through hinge mechanisms; The inner side of the two adjacent sand control screen pieces 2 is blocked in the gap; in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com