Variable valve timing time correction device

A technology of gas distribution phase and timing device, which is applied to valve devices, non-mechanically actuated valves, valve details, etc., can solve the problems of fuel waste, insufficient charging, and excessive charging, and achieves simple manufacturing and convenient installation. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

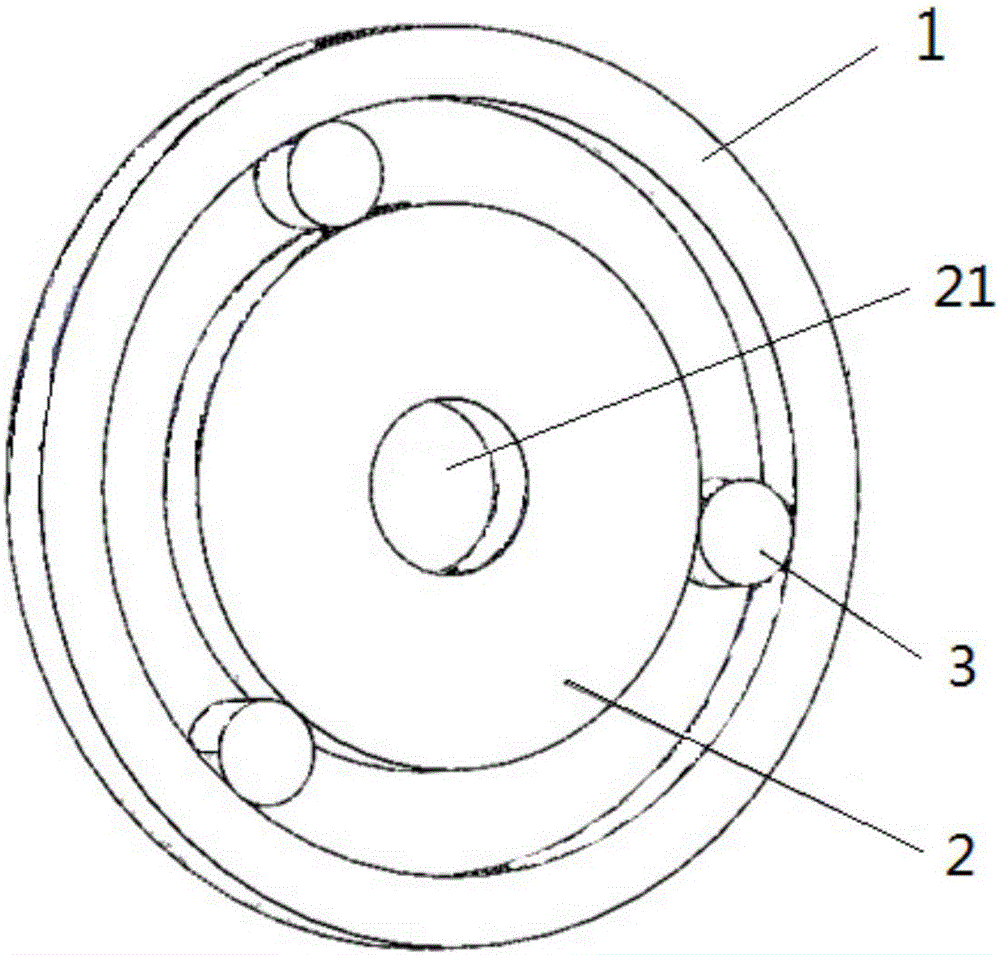

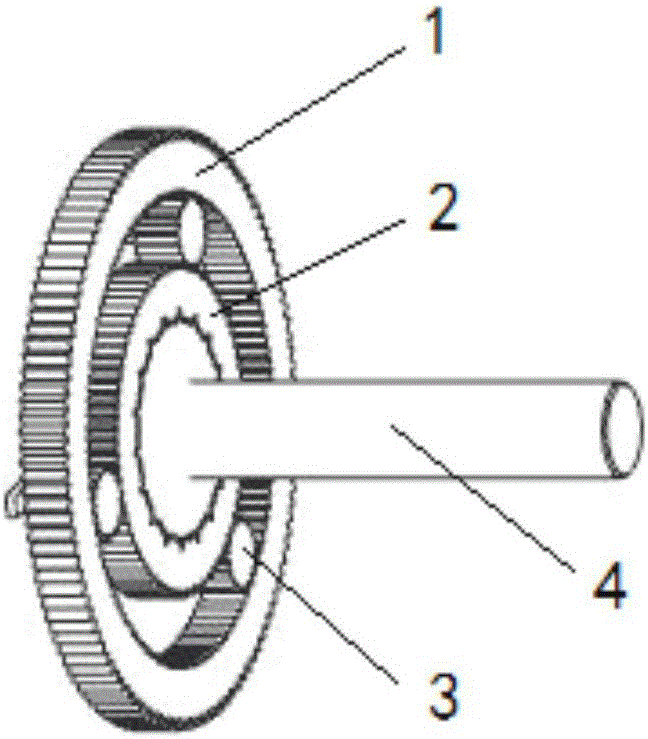

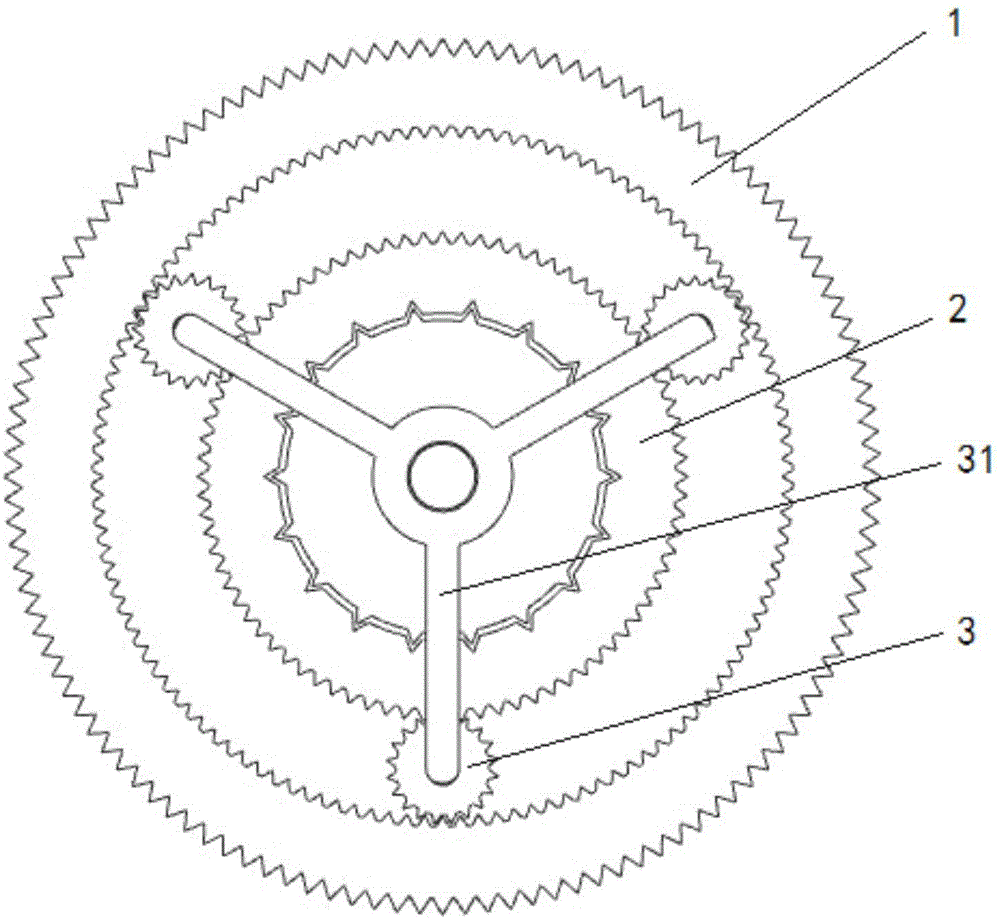

[0020] The invention discloses a variable valve timing device, such as figure 1 , 2 As shown in , 3, it includes an outer sun gear 1 and an inner sun gear 2 arranged coaxially, and a planetary gear 3 located between the outer sun gear and the inner sun gear and meshing with the outer sun gear and the inner sun gear at the same time. The external sun gear, the internal sun gear and the planetary gear constitute a group of epicyclic gear trains, which are used as the variable valve phase timing device of the present invention to replace the timing gears in the traditional valve train. During normal gas distribution, power is input from the outside to the timing device through the external sun gear and output by the internal sun gear.

[0021] The center of the inner sun gear is coaxially provided with a connection hole 21 of the camshaft 4 for valve transmission, which is used for coaxial and fixed connection with the camshaft. The rotation of the inner sun gear drives the cam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com