Movable joint of flat-wall pipe

A movable joint, flat wall technology, applied in the direction of pipe/pipe joint/pipe fitting, pipe, branch pipeline, etc., can solve the problem of inability to ensure the stability of the connection between the joint and the wellbore, achieve locking function guarantee, improve stability, Easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

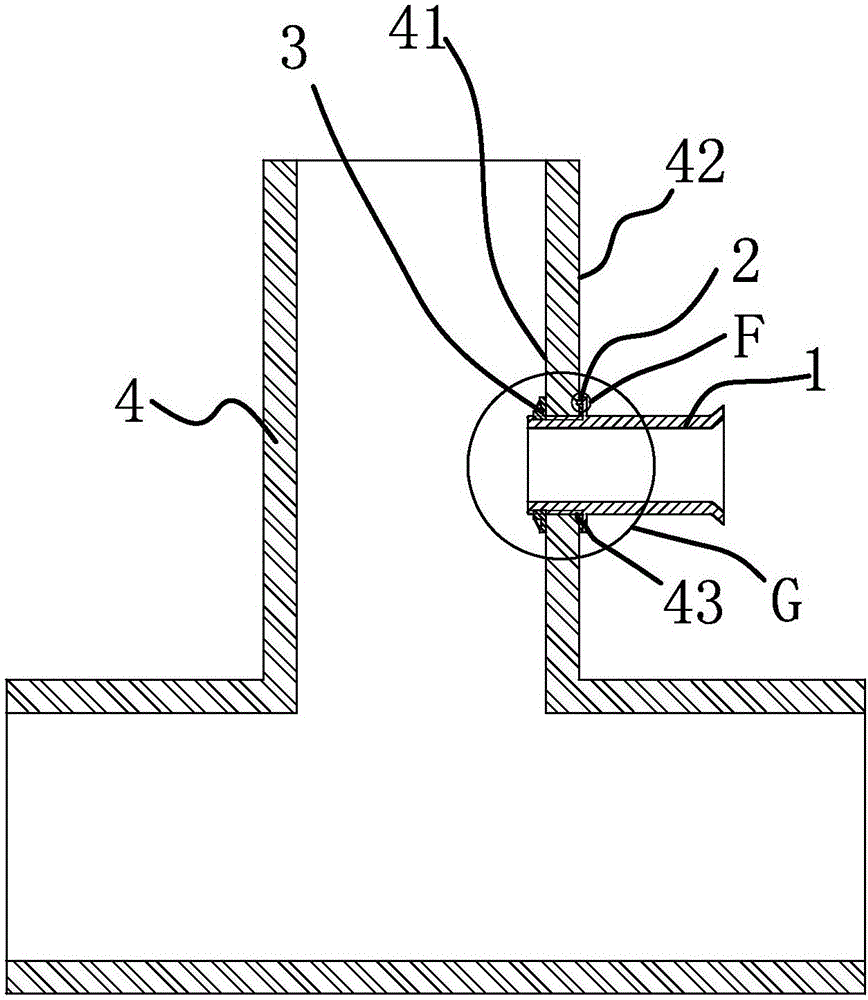

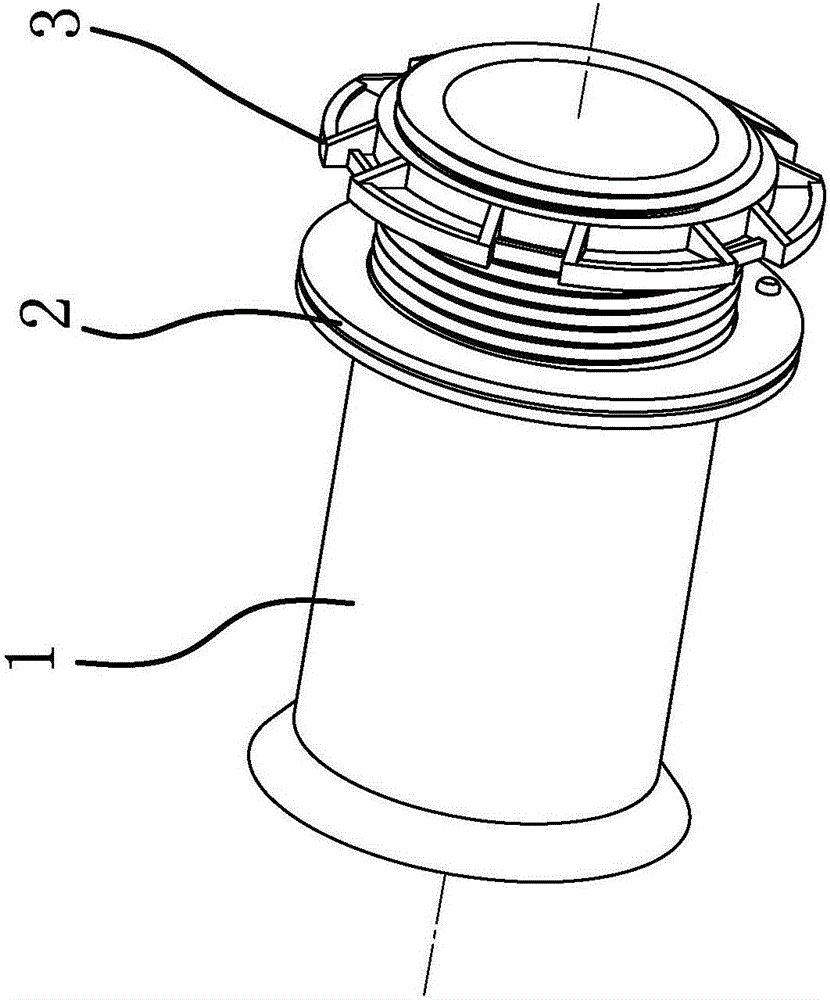

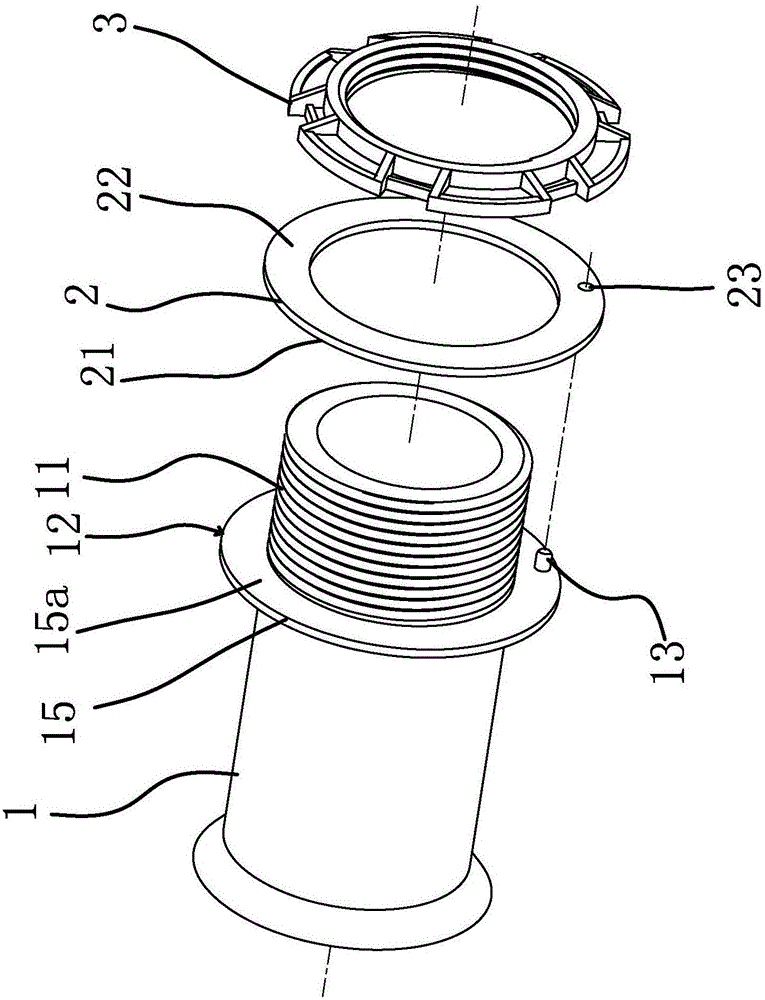

[0049] Such as figure 1 , 2 , 3, 11, and 16, the joint body 1 of the present invention is a middle-pass structure, one end of the joint body 1 is provided with an external thread 11, and the middle part of the joint body 1 has a radially outwardly protruding collar 15, the collar 15 has an annular end surface 15a, and the external thread 11 extends to the annular end surface 15a; the positioning surface 12 of the present invention is the annular end surface 15a on the collar 15 . The end face of the collar 15 protruding from the joint body 1 is ring-shaped. On the one hand, the ring-shaped end face 15a is used as a positioning surface for positioning the sealing ring 2 and acting as an external seal after the movable joint of the present invention is connected; The termination surface of the external thread 11 on the joint body 1 . The positioning surface 12 is provided with a positioning column 13 parallel to the axis of the external thread 11 , the positioning column 13 ex...

Embodiment 2

[0064] Such as Figure 5 , 8 , 12, the structure of this embodiment is similar to that of Embodiment 1, the difference is that the angle formed between the dividing surface 39a and the inner surface of the lock nut 3 in the present invention is less than 90 degrees, and this setting can be used in dividing The retaining surface 1 39a preferably acts on the external thread 11 of the joint body 1 after being stressed, thereby improving the sealing performance between the inner side of the lock nut 3 and the joint body 1 . In the present invention, the angle between the second dividing surface 39b and the locking surface 31 is 90 degrees, which is convenient for the processing of the locking nut 3 .

Embodiment 3

[0066] Such as Figure 6 , 9 , 13, the structure of this embodiment is similar to that of Embodiment 1, the difference is that the angle formed by the dividing surface 39a and the inner surface of the lock nut 3 in the present invention is equal to 90 degrees, which is convenient for locking Nut 3 is machined. The included angle between the second dividing surface 39b and the locking surface 31 in the present invention is less than 90 degrees. This setting can better act on the inner wall 41 when the second dividing surface 39b is stressed, thereby improving the locking surface 31 and the inner wall. 41 tightness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com