Three-shaft adjusting hanging arm joint for hanging projector

A technology for projectors and arm joints, applied in the direction of supporting machines, mechanical equipment, machine tables/brackets, etc., can solve problems such as positioning damage, affecting positioning stability and reliability, and difficult to adjust, achieving good stability and Shock resistance, beneficial to product upgrading, and the effect of large worm transmission ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

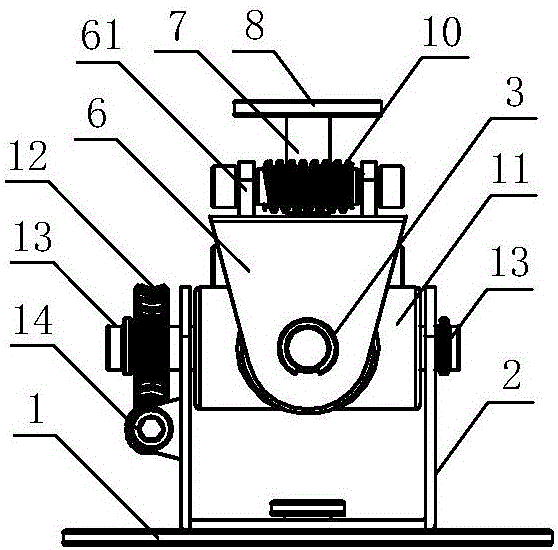

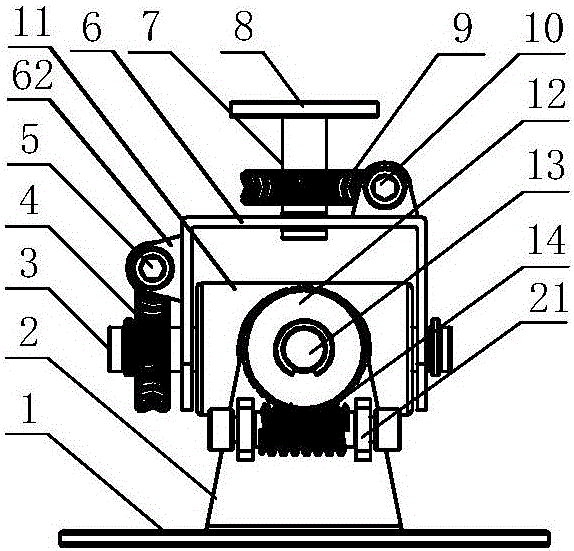

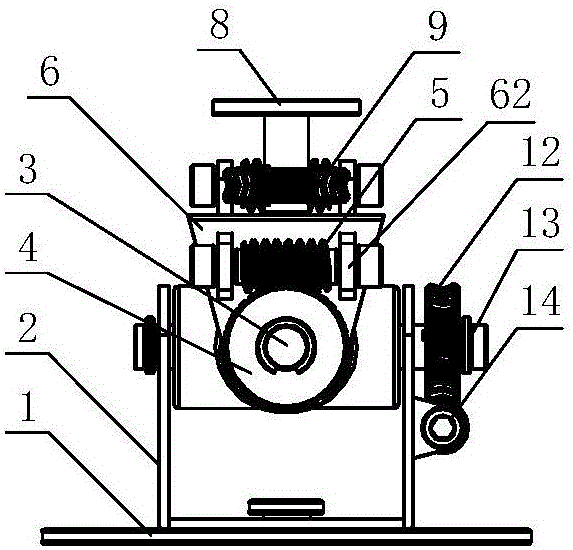

[0030] A three-axis adjustable arm joint for suspending a projector, comprising an arm fixing plate 8 and a projector fixing plate 1;

[0031] The hanging arm fixing plate 8 is connected with the projector fixing plate 1 through a three-axis adjustment mechanism, and the three-axis adjustment mechanism includes an upper U-shaped frame 6, a lower U-shaped frame 2, and an upper / lower U-shaped frame. The X-axis adjustment assembly, the Y-axis adjustment assembly and the Z-axis adjustment assembly;

[0032] The X-axis adjustment assembly includes an X-axis 13, an X-axis gear 12 and an X-axis worm 14,

[0033] The Y-axis adjustment assembly includes a Y-axis 3, a Y-axis gear 4 and a Y-axis worm 5,

[0034] The Z-axis adjustment assembly includes a Z-axis 7, a Z-axis gear 9 and a Z-axis worm 10;

[0035] The upper U-shaped frame 6 is connected to the lower U-shaped frame 2 through a cross shaft assembly, and the centers of the two vertical axes of the cross shaft assembly are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com