Control device for discharge of water vapor in dry kettle

An emission control and water vapor technology, applied in the drying of solid materials, granular materials, drying, etc., can solve the problems of external emission, reduce production efficiency, affect production efficiency, etc., to avoid waste, improve emission efficiency, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

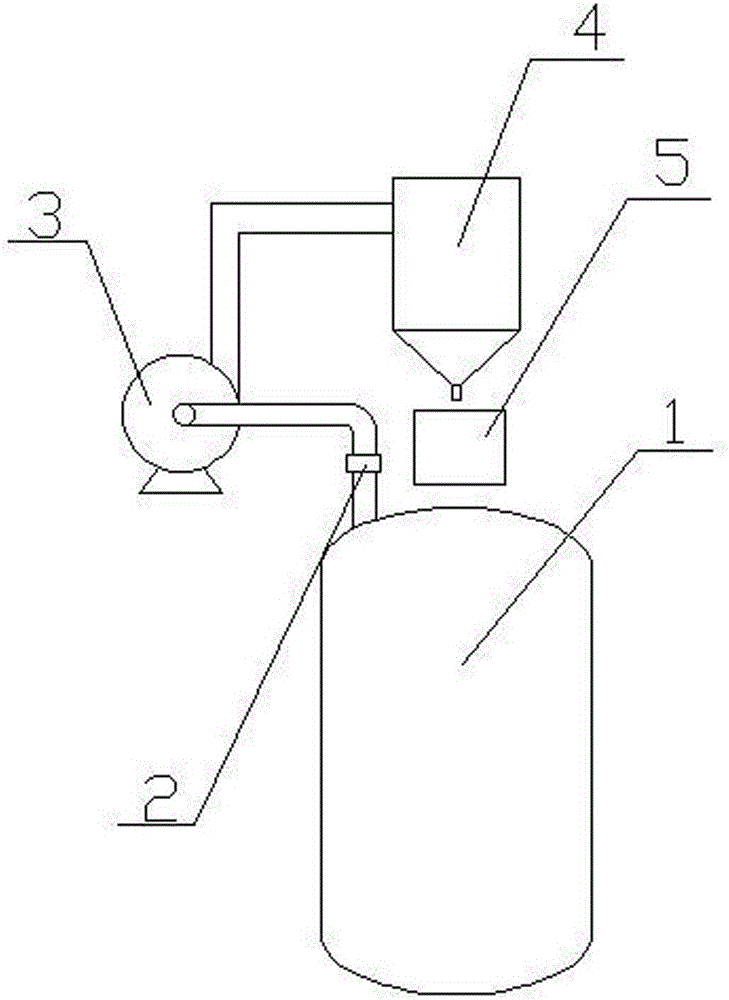

[0010] Such as figure 1 As shown, the drying kettle water vapor emission control device of the present invention includes a drying kettle 1, the whole of the drying kettle 1 is kept closed, and the top of the drying kettle 1 is connected to the air inlet of the induced draft fan 3 through a pipeline, and the induced draft fan 3 is selected from a centrifugal induced draft fan. The fan, the section of pipeline between the drying kettle 1 and the induced draft fan 3 is equipped with a valve 2, and the valve 2 is used to control the air intake of the induced draft fan 3. The air outlet of the induced draft fan 3 is connected with a cyclone separator 4 through a pipeline, and a collection box 5 is arranged below the cyclone separator 4 .

[0011] When a large amount of water vapor is generated from the drying material in the drying kettle 1, start the induced draft fan 3 and the cyclone separator 4, and open the valve 2 to the maximum, so that the water vapor can be discharged qui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com