Sound box mesh enclosure manufacturing method, sound box mesh enclosure and sound box

A production method and speaker technology, applied in the direction of frequency/direction characteristic device, transducer shell/cabinet/bracket, etc., can solve problems such as abnormal sound speaker net cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

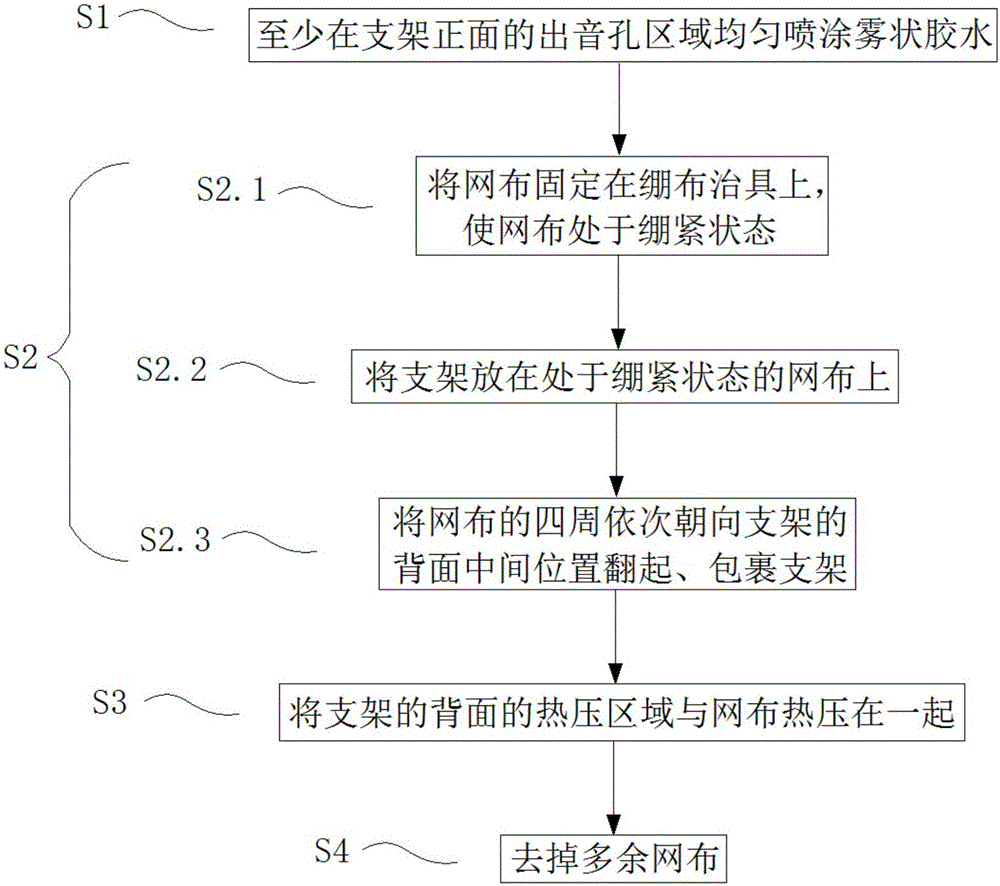

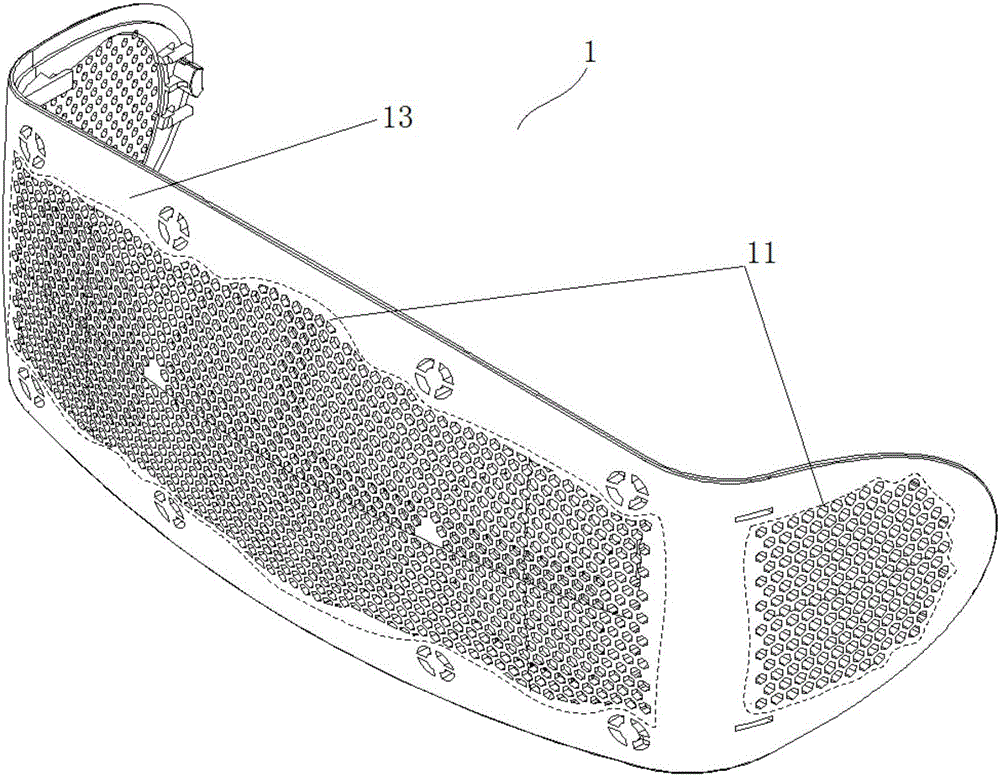

[0030] refer to Figure 1 to Figure 7 , In this embodiment, a method for manufacturing a speaker net cover is provided. The manufacturing method includes the steps of setting spray glue at least in the sound outlet area 11 on the front of the bracket 1 and bonding the mesh cloth 2 on the sound outlet area 11 . Wherein, the sound hole area 11 is the area covering the sound hole and the mesh cloth 2 colliding with this area will generate abnormal sound.

[0031] Liquid glue is easy to flow, it will seep out of the mesh 2 and affect the appearance, and it may block the sound hole and affect the sound quality. In comparison, the mist glue will neither seep out of the mesh 2 nor block the sound hole. This in turn avoids a corresponding impact on appearance and sound quality. On the basis that the use of mist glue has no effect on the sound quality, the mist glue makes the mesh 2 and the bracket 1 stick together at least at the sound outlet area 11, and the mesh 2 will not collide...

Embodiment 2

[0047]In this embodiment, a speaker grille is provided, which is manufactured by the manufacturing method of the speaker grill in the first embodiment.

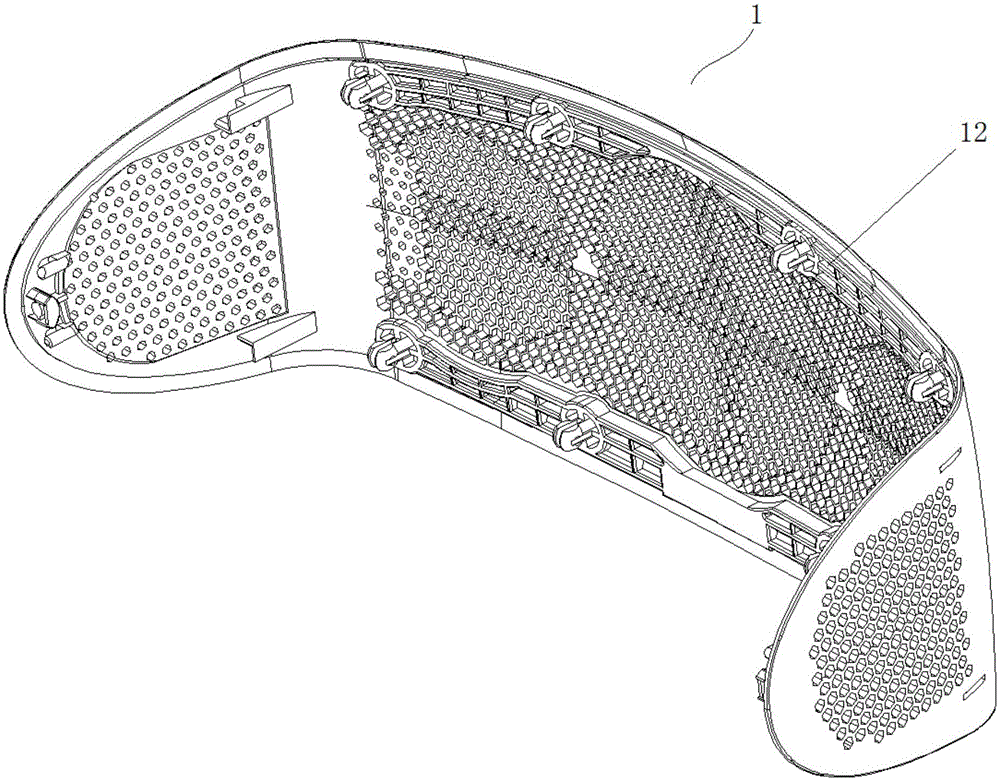

[0048] Specifically, the speaker net cover includes a bracket 1 and a mesh cloth 2. The mesh cloth 2 is bonded to the sound hole area 11 on the front of the bracket 1 by spray glue, and the edge of the mesh cloth 2 is bonded to the heat-pressed area 12 on the back of the bracket 1. Heat pressed together.

[0049] The sound box net cover of this embodiment, after being used for a certain period of time, will not cause abnormal sound due to the loose mesh 2 colliding with the bracket 1, and the sound quality will not decrease due to the loose mesh 2.

Embodiment 3

[0051] In this embodiment, a sound box is provided, and the sound box includes the sound cover of the second embodiment. After being used for a certain period of time, the speaker will not experience abnormal sound caused by the impact of the loose mesh 2 on the bracket 1, and the sound quality will not decrease due to the loose mesh 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com