Filter and method for producing same

A filter and filter layer technology, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., to achieve the effects of small flow resistance, high air flow, and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0050] Example 1

[0051] Dissolve or decompose the following components in 900ml of water:

[0052] -80-100, preferably 90g bentonite

[0053] -30-60, preferably 45g activated carbon

[0054] -20-50, preferably 35g methylimidazole ethyl sulfate,

[0055] -2-8, preferably 5g N-(L-α-aspartyl)-L-phenylalanine methyl ester

[0056] - 4-8, preferably 6 g of sodium alginate.

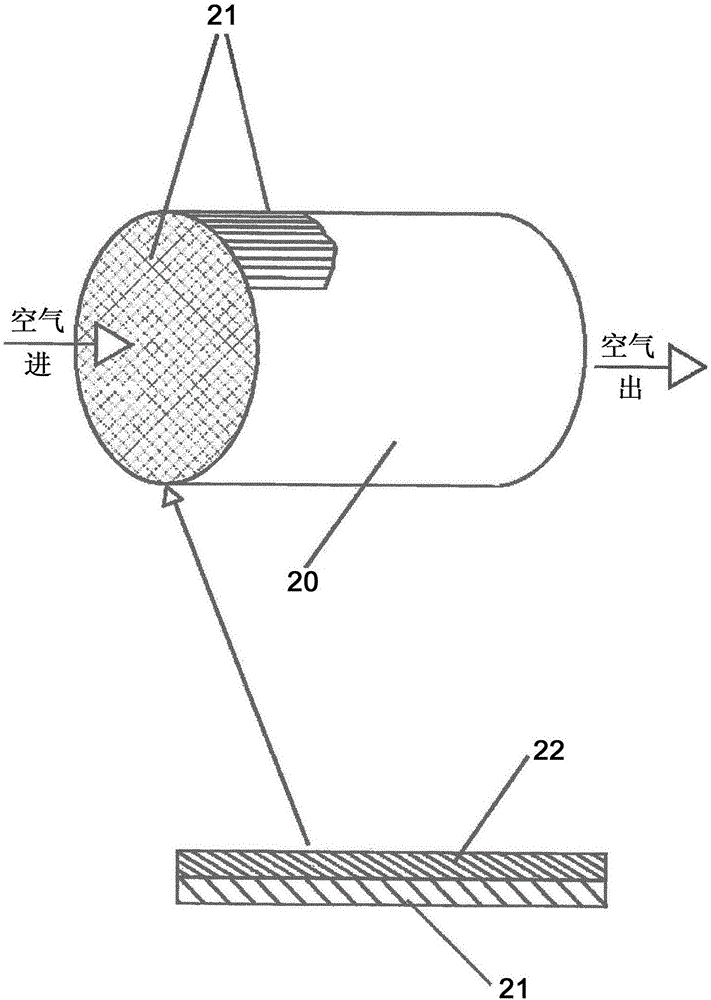

[0057] The solvent or dispersion thus produced is applied to the carrier body 21, preferably by dipping the carrier body into the solvent. The carrier thus pretreated was then introduced into a 2% aqueous calcium chloride solvent. The insoluble alginate is produced by the incorporation of calcium (or another suitable multivalent metal ion), which is used to gel or solidify the filter layer. Next dry in a stream of air. In a next step, an ionic liquid is additionally applied to the fixed filter layer. For this purpose, the carrier is immersed in 1-ethyl-2-methylimidazolium ethyl sulfate or sprayed wi...

Example Embodiment

[0058] Example 2

[0059] As in Example 1, the solvents or mixtures described there were produced and applied to the surface of the carrier. The filter layer is fixed in a second step, however, directly by immersing the support body in 1-ethyl-2-methylimidazolium ethyl sulfate and subsequently drying it in a stream of air. In this variant of the invention, the fixation or gelling of the filter layer and the application of the ionic liquid are thus carried out in a single step.

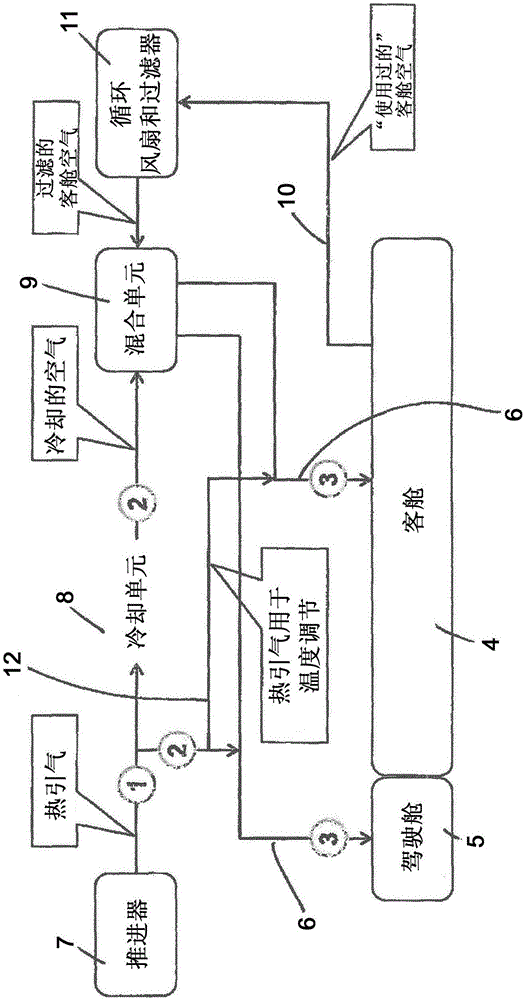

[0060] figure 2 The air conditioning system of a passenger aircraft is schematically shown. The passenger cabin 4 and cockpit 5 of the aircraft are supplied with air by supply pipes 6 . The air is a mixture of thermostated fresh air and filtered recirculated cabin air.

[0061] Fresh air is provided by a so-called bleed air branch from the compressors of one or more propellers 7 . The main part of the bleed air (temperature typically 215°C - 260°C) which is heated due to compression is sent to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap