Turbo charger having noise, vibration and harshness (NVH)-reducing device

A turbocharger and roughness technology, which is applied to the components of pumping devices for elastic fluids, gas turbine devices, engine components, etc., can solve problems such as the reduction of air compression efficiency, and achieve the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

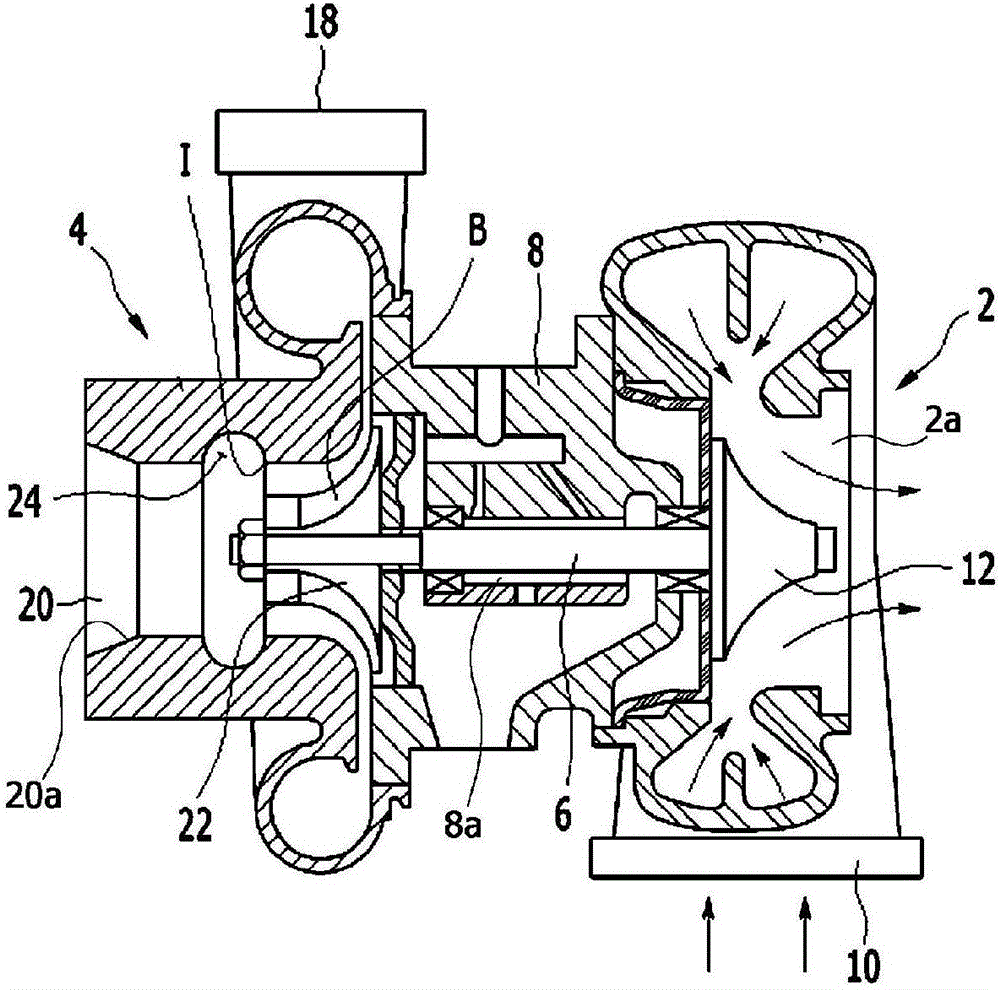

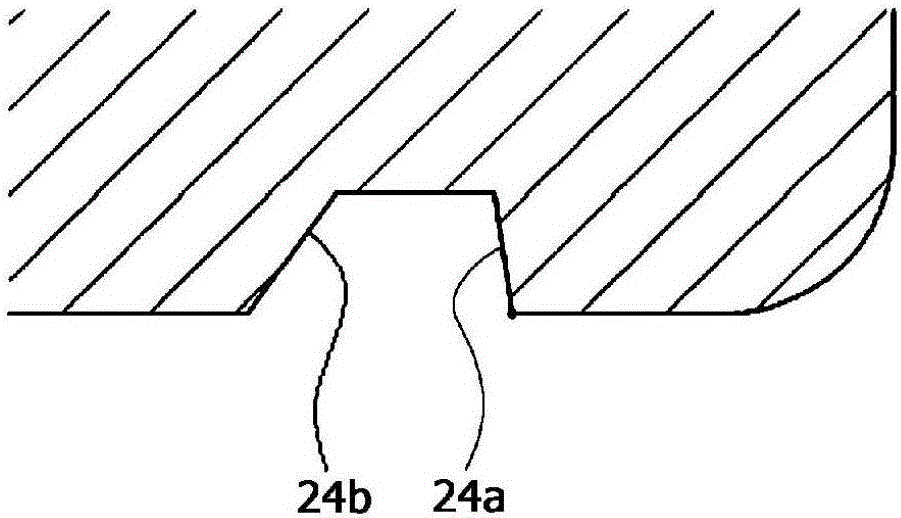

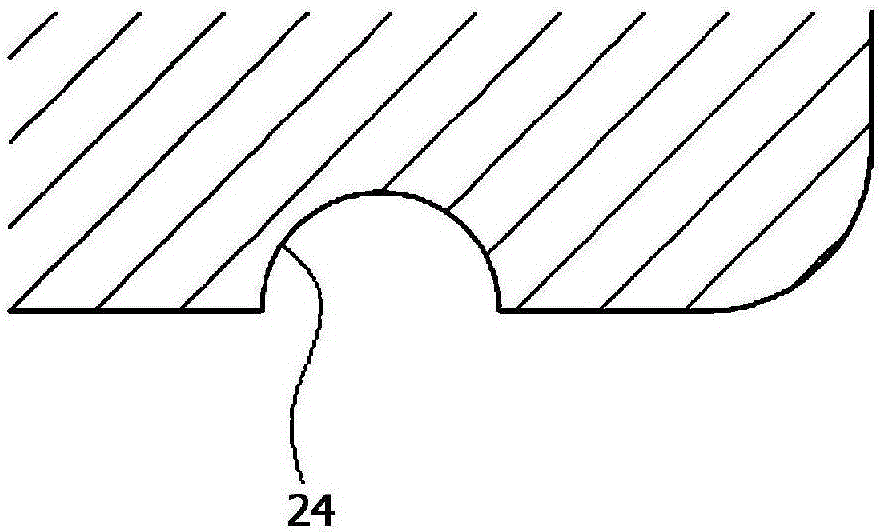

[0029] According to an aspect of the present invention, a turbocharger having a noise, vibration and harshness (NVH) reducing device includes: a central housing including a bore into which an axial shaft is inserted, and one of the shafts One side is coupled with the turbine impeller, and the other side of the shaft is coupled with the compressor impeller; the turbine casing is arranged on one side of the center casing, and an exhaust gas inlet and an exhaust gas outlet are formed on the turbine casing, and a The turbine impeller; the compressor casing is arranged on the other side of the central casing, an air inlet and an air outlet are formed on the compressor casing, and a compressor impeller is arranged on the compressor casing, when the turbine impeller when rotating and the compressed air moves toward the air outlet, the compressor impeller compresses the air introduced from the air inlet; Between the outlets, the air flow that occurs when the compressor wheel turns is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com