A high-efficiency settling device

A settling device and high-efficiency technology, which can be used in settling tanks, separation methods, filtration and separation, etc., can solve the problems of slow concentration and settling speed, bulky volume, and increased construction costs, so as to speed up the concentration speed, improve the concentration efficiency, and reduce the difficulty of construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

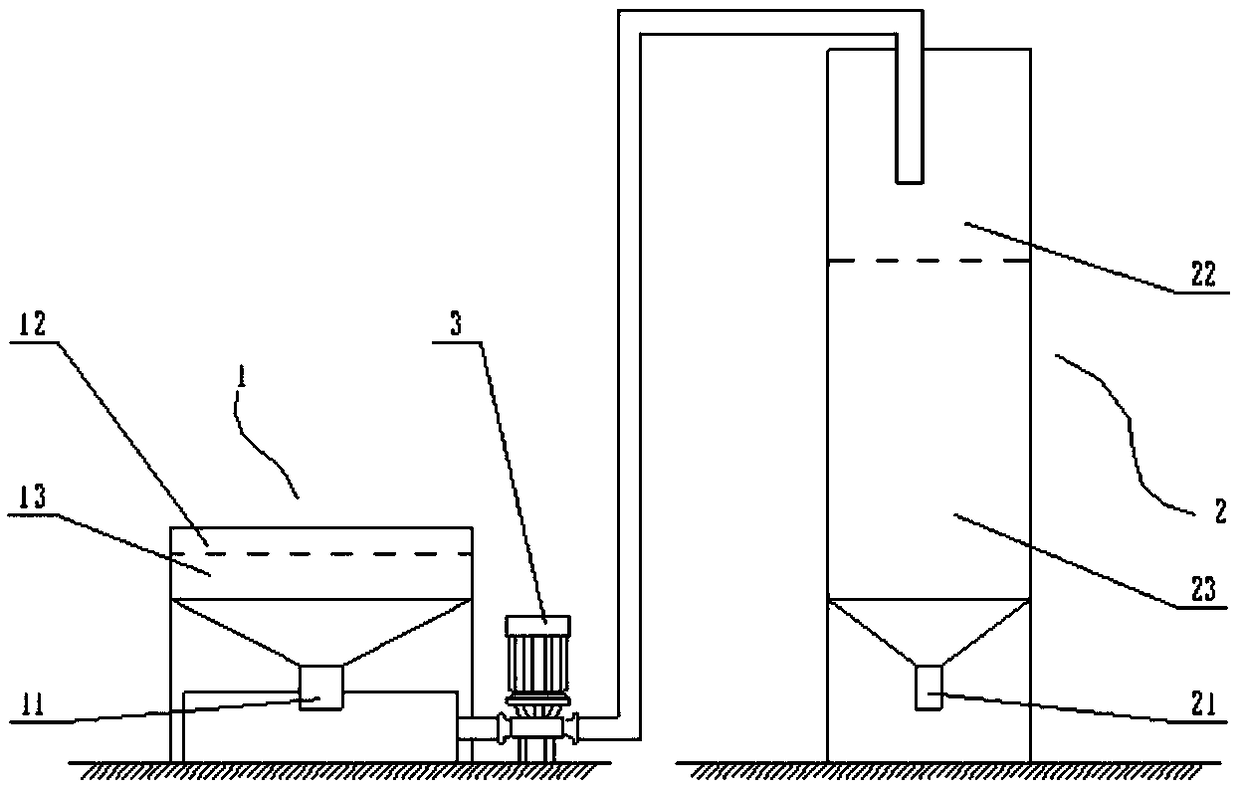

[0036] The technical scheme adopted in this embodiment is as follows: figure 1 As shown, it includes the primary settling tank 1 and the secondary settling tank 2 connected in series.

[0037] Both the primary settling tank 1 and the secondary settling tank 2 are cylindrical.

[0038] The column height of the primary settling tank 1 is H 1 , the cylinder diameter of the primary settling tank 1 is D 1 , the column height of the secondary settling tank 2 is H 2 , the cylinder diameter of the secondary settling tank 2 is D 2 .

[0039] Height H of primary settling tank 1 1 ≤5.0m, and the height H of the primary settling tank 1 1 and the diameter D of the primary settling tank 1 1 Ratio H 1 / D 1 ≤0.3;

[0040] The height H of the secondary settling tank 2 2 ≥5.0m, and the height H of the secondary settling tank 2 2 and the diameter D of the secondary settling tank 2 2 Ratio H 2 / D 2 ≥5;

[0041] Diameter D of primary settling tank 1 1 and the diameter D of the sec...

Embodiment 2

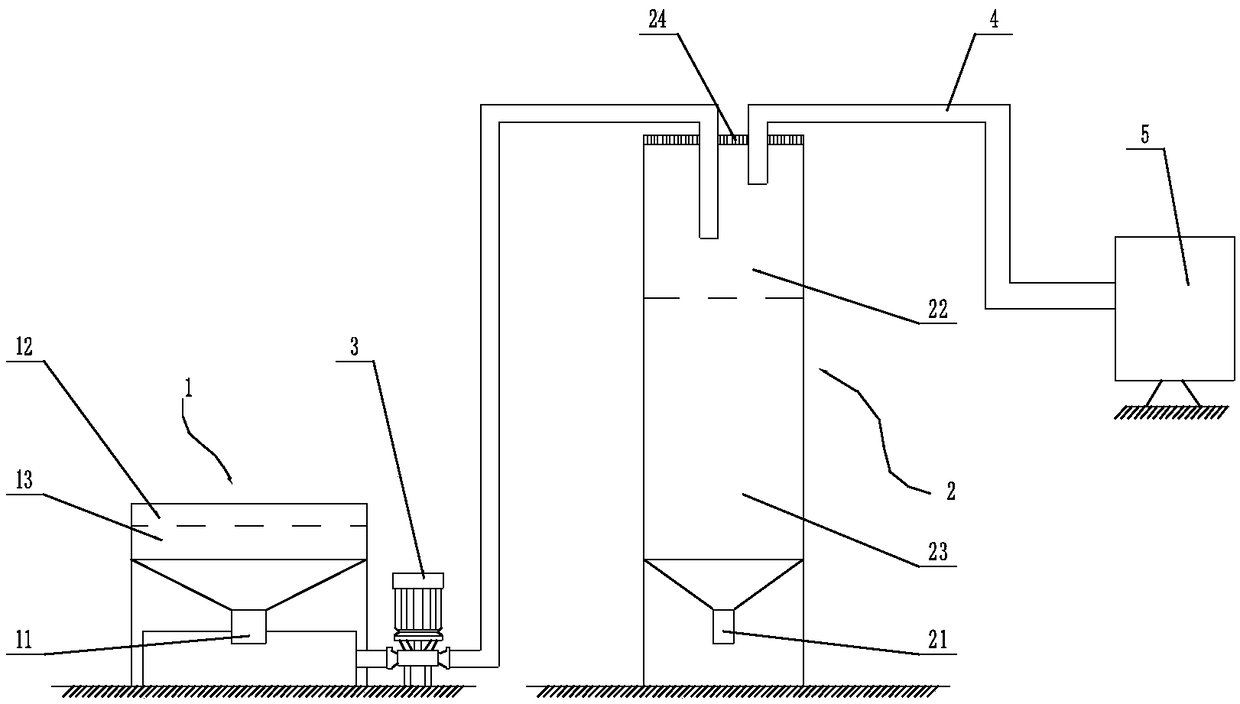

[0046] The technical scheme adopted in this embodiment is as follows: figure 2 As shown, it includes the primary settling tank 1 and the secondary settling tank 2 connected in series.

[0047] In the present embodiment, the bottom surface of the primary settling tank 1 is a conical surface, and the bottom surface of the primary settling tank 1 is provided with a primary underflow slurry outlet 11. On the upper surface of the conical surface, the gravity of the solid particles is decomposed into The downward force and the force perpendicular to the cone surface, the reaction force formed by the force perpendicular to the cone surface can be used for further concentration and settlement between solid particles, and the force along the cone surface can make the solid particles along the cone while concentrating and settling. The surface slowly slides down and flows out from the first-level underflow slurry outlet 11.

[0048] In other embodiments, the bottom surface of the prim...

Embodiment 3

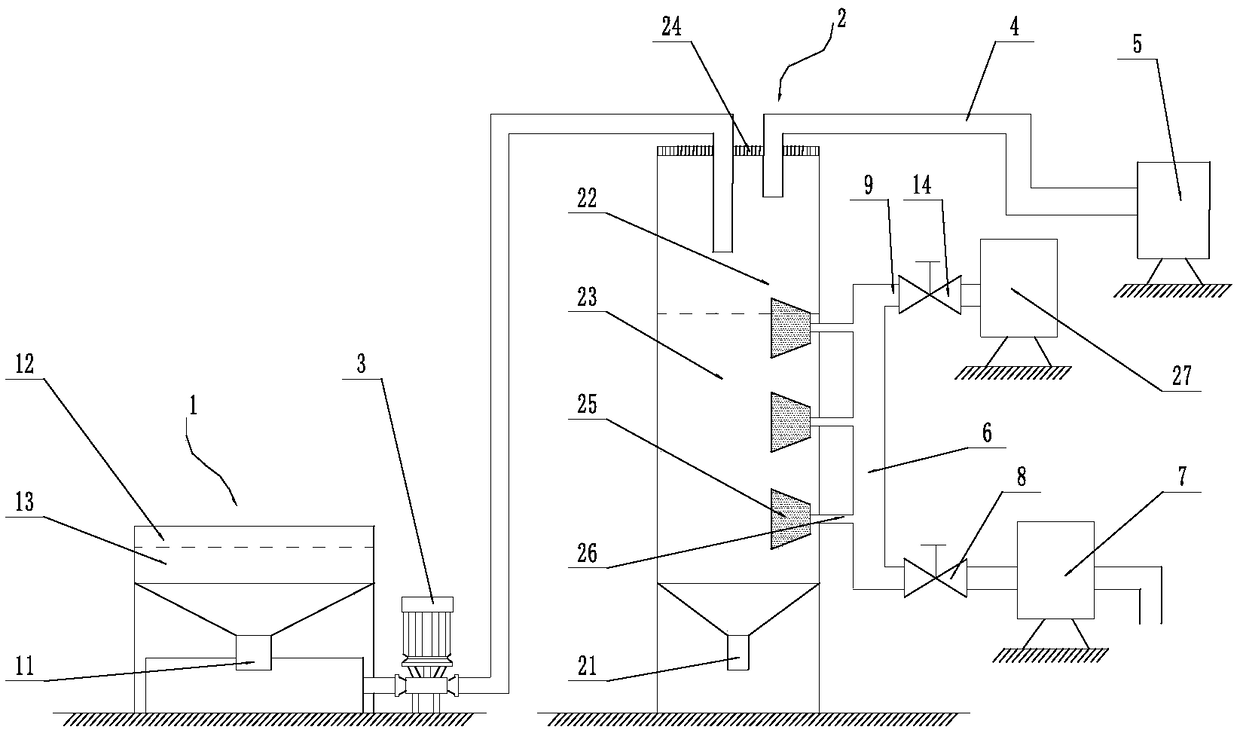

[0058] See image 3 As shown, the difference between embodiment 3 and embodiment 2 is that at least one microporous filter plate 25 is also arranged in the secondary settling tank 2, and the microporous filter plate 25 is all vertically fixed on the inner wall of the secondary settling tank 2 , the liquid outlet pipe 26 of the microporous filter plate 25 passes through the tank wall of the secondary settling tank 2, and the liquid outlet pipe of the microporous filter plate 25 is tightly fitted with the tank wall of the secondary settling tank 2 to prevent the slurry from leaking out , the liquid outlets of the liquid outlet pipe 26 of the microporous filter plate 25 are all connected to a liquid discharge pipe 6, and the filtrate filtered out by the microporous filter plate 25 is discharged through the liquid discharge pipe 6.

[0059] The microporous filter plate 25 can discharge the water in the slurry at any time, which speeds up the speed of sedimentation and concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com