Composition for improving settling effect of solid particles, dense synergist comprising the same, preparation method and application

A technology for solid particles and compositions, which is applied in the field of thickening synergists and compositions for improving the sedimentation effect of solid particles, can solve the problems such as the underflow concentration of the thickener needs to be improved, and achieves easy industrial application, improved underflow concentration, and less dosage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

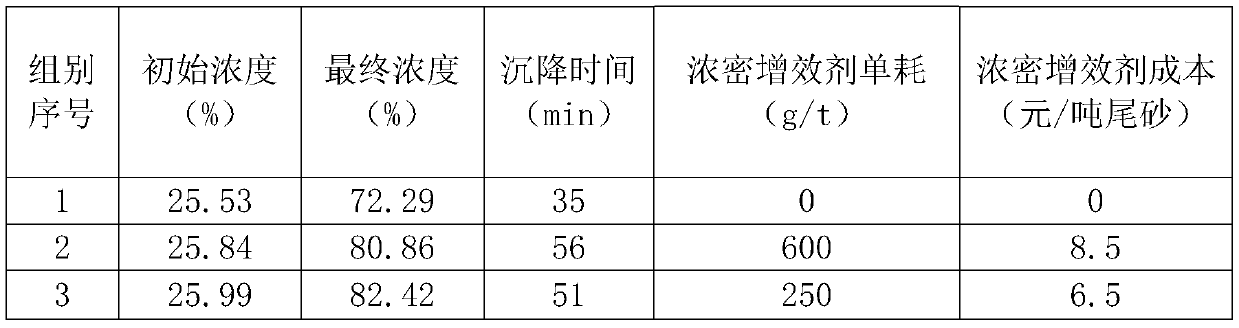

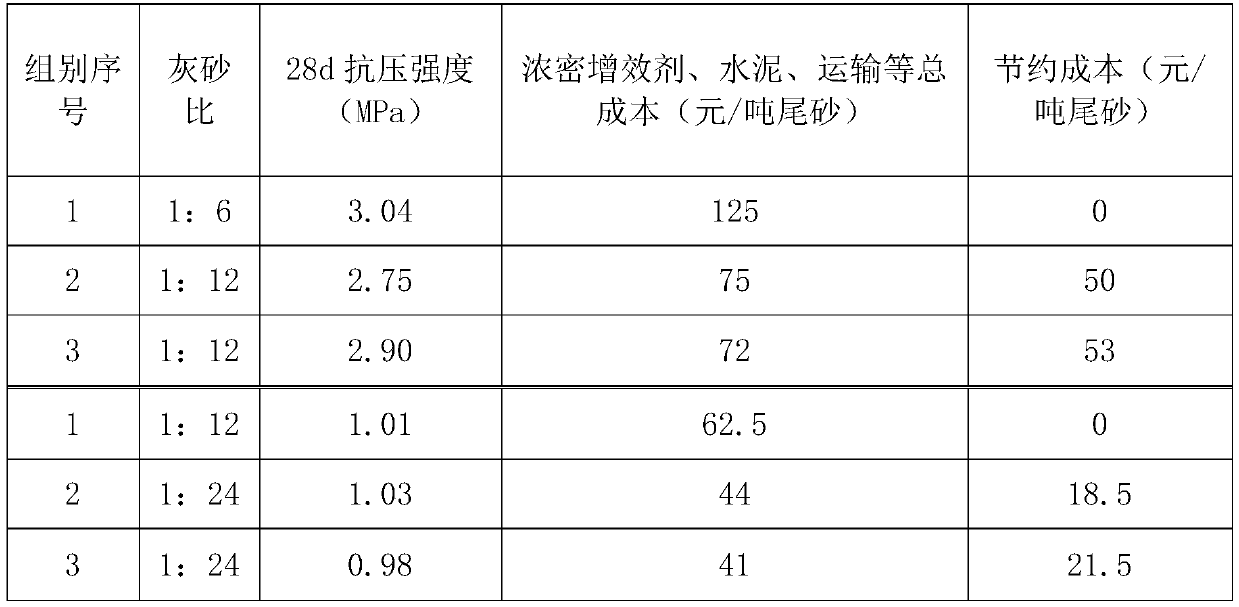

Examples

Embodiment 1

[0029] 1. Material preparation

[0030] Weigh each component according to the following parts by mass: 36 parts of complexing components, 27 parts of air-entraining components, 27 parts of dispersion components, and 9 parts of linear ionic polymer components;

[0031] Wherein, the complexing component is tetrasodium hydroxyethylidene diphosphonate, the air-entraining component is diethanol monoisopropanolamine, and the dispersing component is maleic acid acrylic acid copolymer sodium salt with a mass ratio of 3:1:1, The mixture of polyethylene glycol monomethyl ether and sodium polyaspartate, the linear ionic polymer component is sodium p-aminobenzenesulfonate-formaldehyde-phenol copolymer.

[0032] 2. Mixing

[0033] Mix maleic acid acrylic acid copolymer sodium salt, polyethylene glycol monomethyl ether and sodium polyaspartate according to the above mass ratio, then add sodium p-aminobenzenesulfonate and mix well, then add hydroxyethylidene diphosphonic acid tetra Sodium ...

Embodiment 2

[0037] 1. Material preparation

[0038] Weigh the components according to the following parts by mass: 17 parts of complexing components, 17 parts of air-entraining components, 50 parts of dispersion components, and 17 parts of linear ionic polymer components;

[0039] Among them, the complexing component is polyether polyamino methylidene phosphoric acid (PAPEMP), the air-entraining component is diethanol monoisopropanolamine, and the dispersing component is sodium maleic acid acrylic acid copolymer with a mass ratio of 4:2:1 A mixture of salt, polyethylene glycol monomethyl ether and sodium polyaspartate, the linear ionic polymer component is fatty acid methyl ester polyoxyethylene ether (FMEE).

[0040] 2. Mixing

[0041] Mix the maleic acid acrylic acid copolymer sodium salt, polyethylene glycol monomethyl ether and sodium polyaspartate according to the above mass ratio, then add FMEE and mix well, then add PAPEMP and diethanol monoisopropanolamine, mix well , to obtain ...

Embodiment 3

[0045] 1. Material preparation

[0046] Weigh the components according to the following parts by mass: 37.5 parts of complexing components, 25 parts of air-entraining components, 25 parts of dispersion components, and 12.5 parts of linear ionic polymer components;

[0047] Wherein, the complexing component is tetrasodium hydroxyethylidene diphosphonate, the air-entraining component is diethanol monoisopropanolamine, and the dispersing component is maleic acid acrylic acid copolymer sodium salt with a mass ratio of 3:1:1, A mixture of polyethylene glycol monomethyl ether and sodium polyaspartate, and the linear ionic polymer component is sodium p-aminobenzenesulfonate.

[0048] 2. Mixing

[0049] Mix maleic acid acrylic acid copolymer sodium salt, polyethylene glycol monomethyl ether and sodium polyaspartate according to the above mass ratio, then add sodium p-aminobenzenesulfonate and mix well, then add hydroxyethylidene diphosphonic acid tetra Sodium and diethanol monoisopr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com