Basin assembly and washing machine

A component and water basin technology, applied in the field of washing machines, can solve the problems that the design of dishwashers cannot meet the cleanliness requirements, and achieve the effect of improving cleaning cleanliness, preventing leakage, and preventing water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

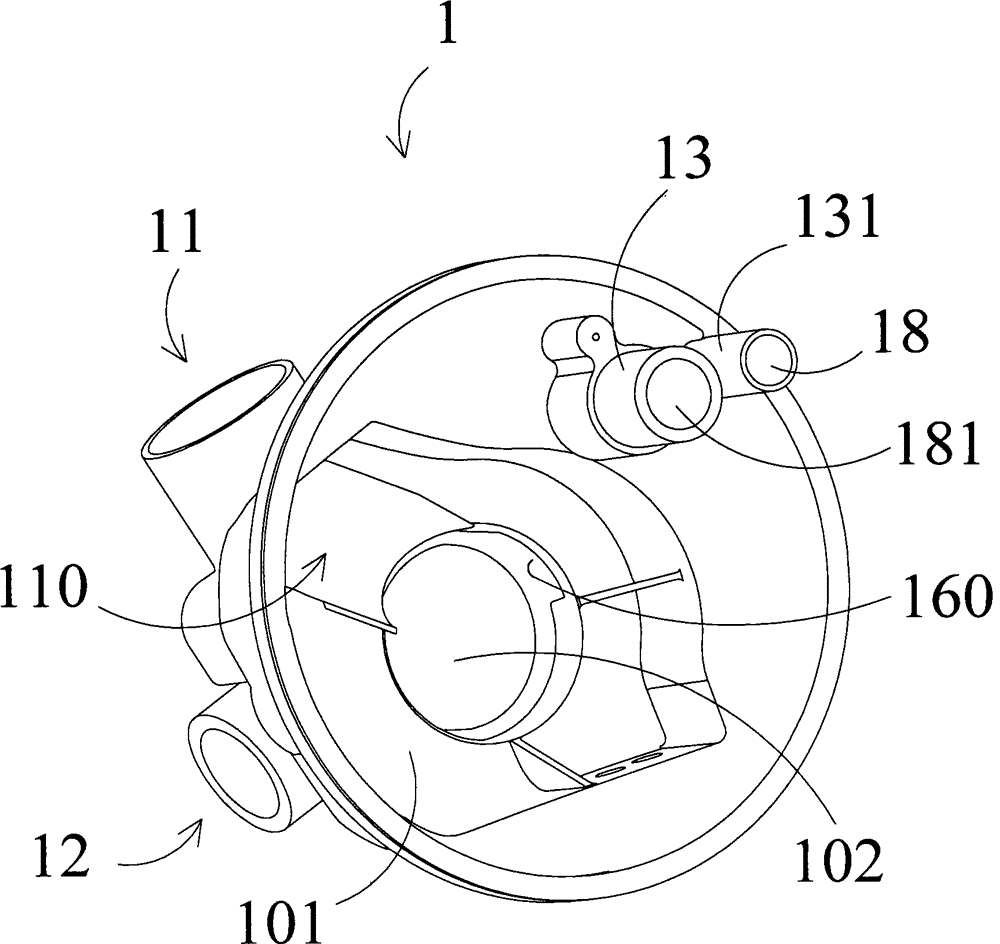

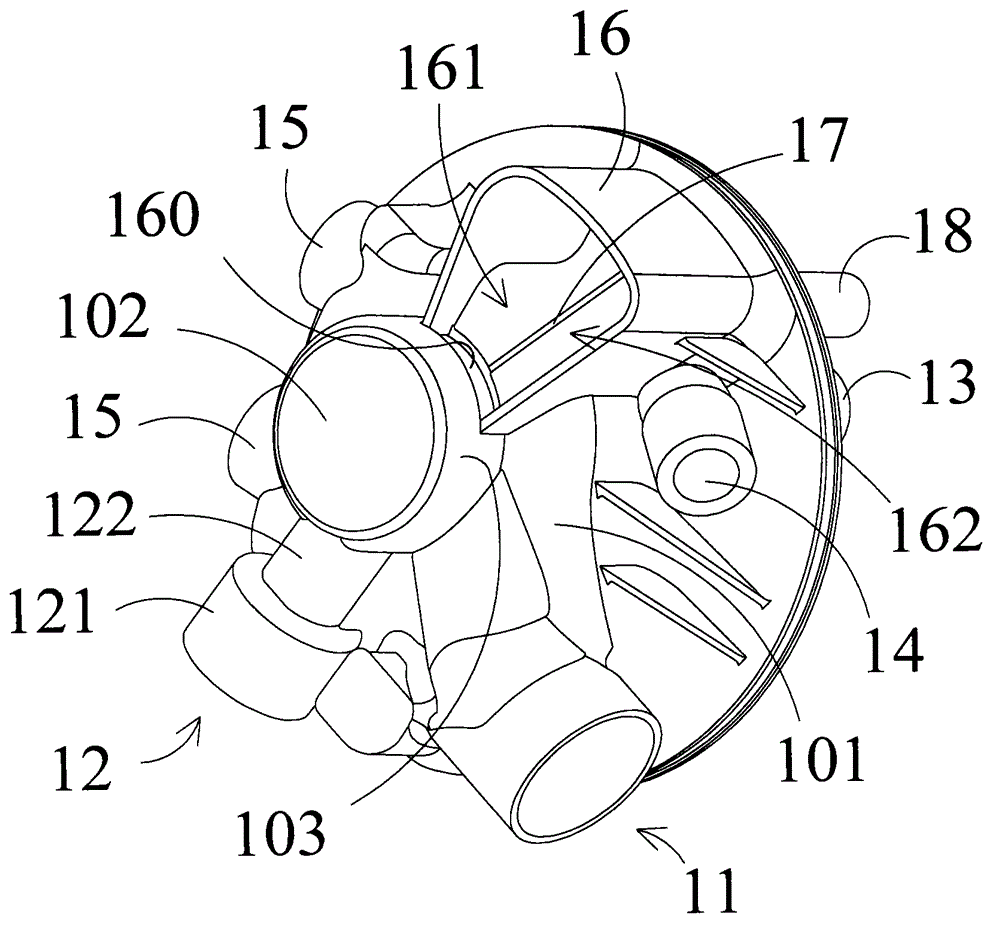

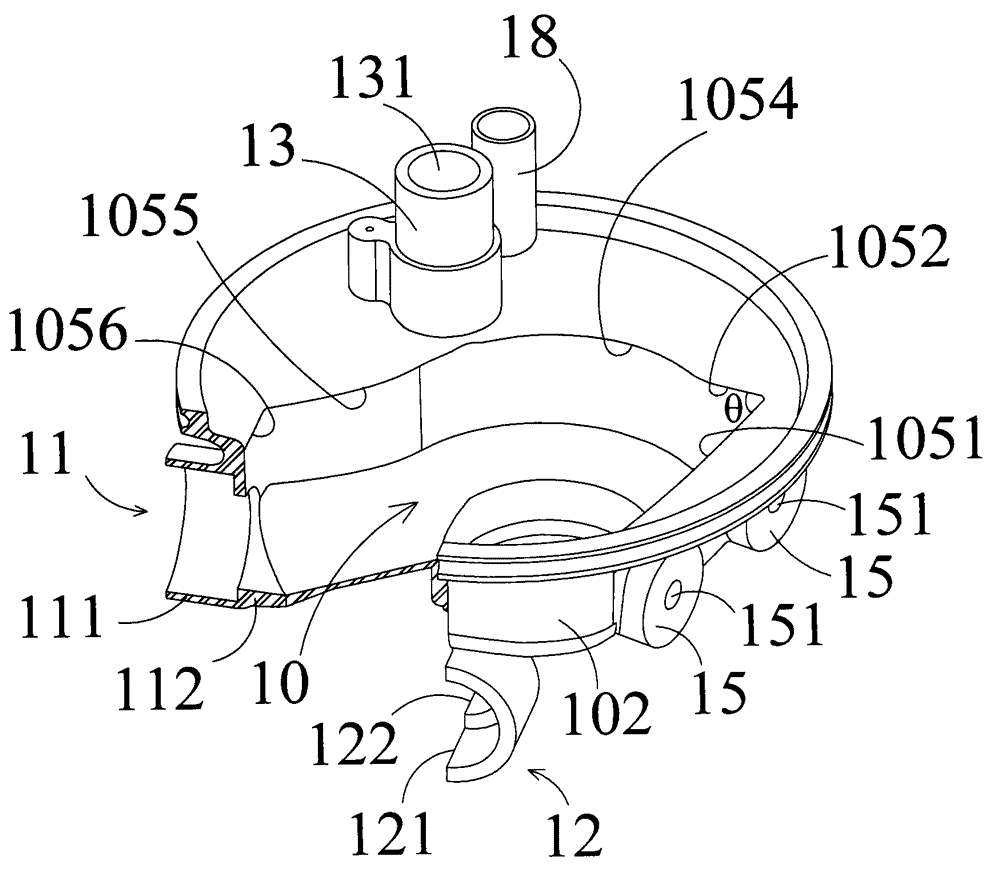

[0037] Such as Figure 1 to Figure 4 As shown, an exemplary embodiment of the water basin assembly of the present invention includes a body 1 and a water collection chamber 10 integrally formed on the body 1, a circulation pump installation port 11, a drain pump installation port 12, a lower spray arm seat 13 and a lower Spray arm inlet pipe 14.

[0038] The body 1 may be in the shape of a disc, but not limited thereto, it may be in other shapes. The outer circumference of the body 1 is provided with a sealing groove 100 (see Figure 4 ), a sealing ring (not shown in the figure) can be placed in the sealing groove 100. When the water basin assembly of the present invention is installed on other parts such as the inner container of the washing machine, the sealing ring in the sealing groove 100 can effectively prevent water leakage.

[0039] The water collection chamber 10 is formed by the body 1 being recessed downwards. The water collection chamber 10 has a bottom wall 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com