Unmanned ship onboard vehicle warehouse system

A technology of unmanned aerial vehicles and unmanned ships, which is applied in the direction of aircraft ships, water-based ship navigation equipment, ships, etc., and can solve the problem of poor image transmission and remote transmission of control signals, limited battery life, and limited monitoring height, etc. To improve work efficiency and duty performance, solve the difficulties of water endurance and large-scale communication, and make up for the disadvantages of operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

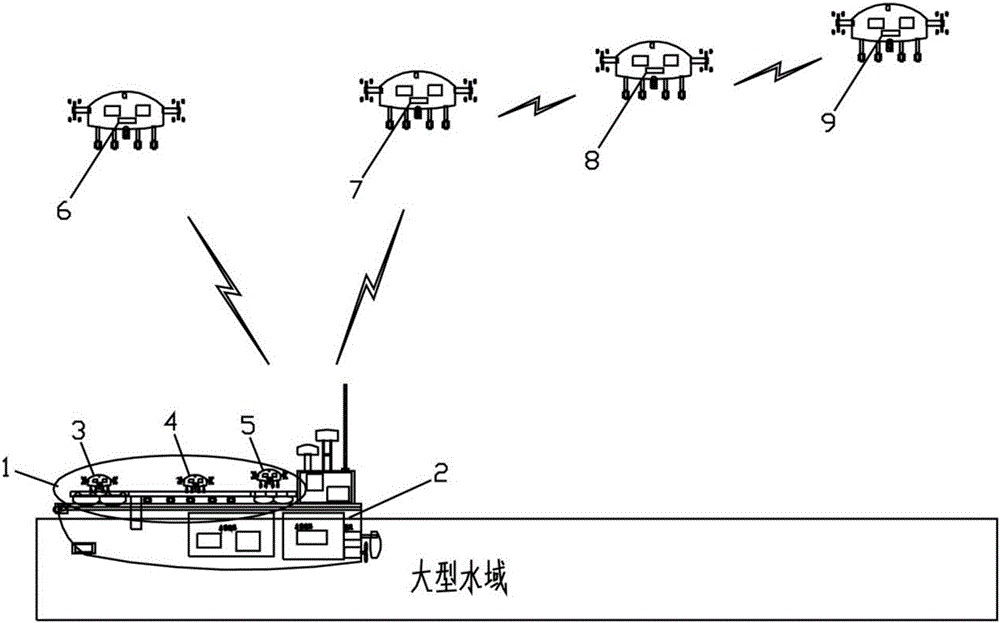

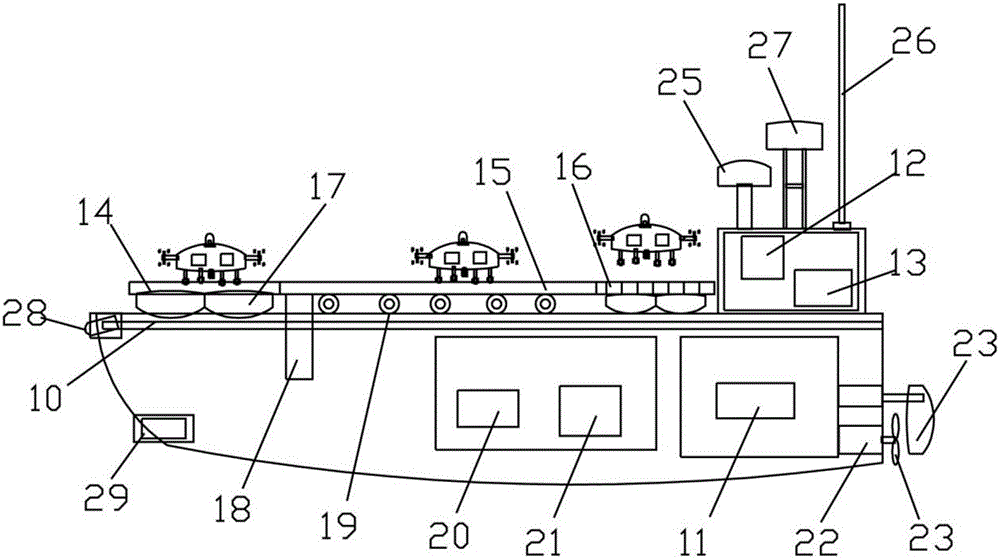

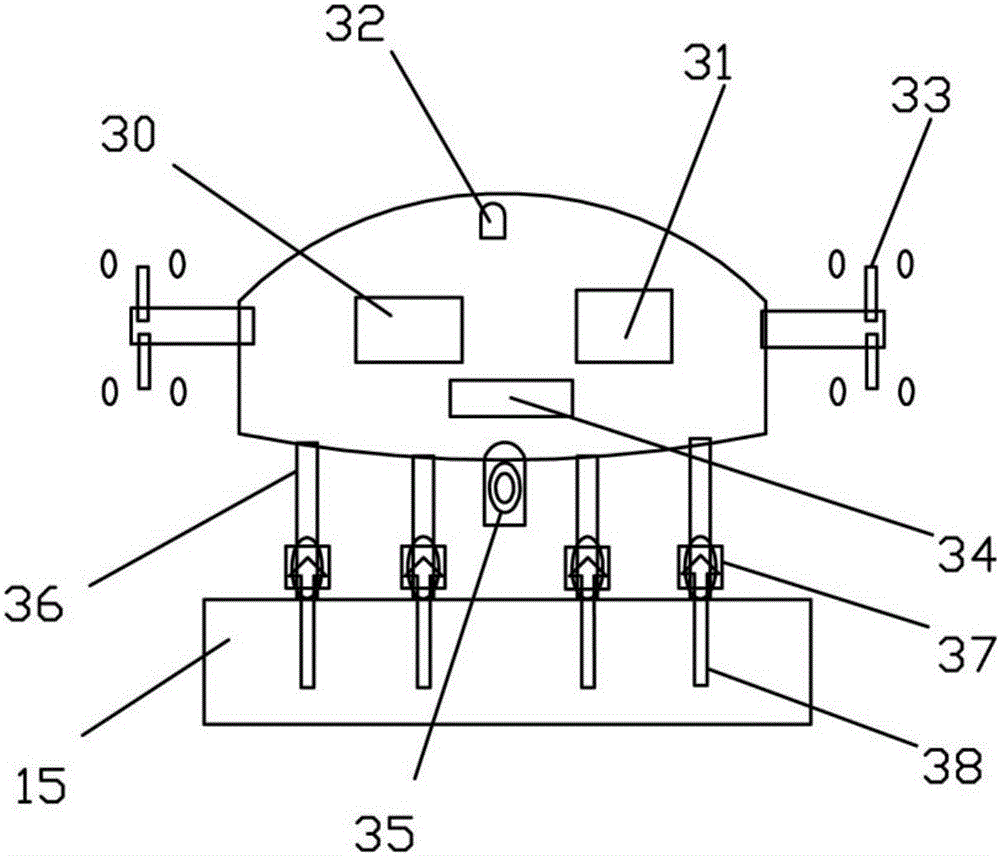

[0018] Such as Figure 1 to Figure 3 As shown, an unmanned ship hangar system described in the present invention includes a drone group 1, an unmanned ship 2 and a communication system. The drone group 1 is composed of two or more drones. The human-machine body and the onboard control system are composed. The unmanned ship 2 is equipped with a shipboard platform 10, a shipboard control system, and a shipboard power system. The drone group is set on the shipboard platform 10. The communication system includes shipboard communication equipment. The on-board communication equipment installed on the UAV, the on-board control system and the on-board communication equipment are set correspondingly, and the on-board control system is set correspondingly to the on-board communication equipment. The above constitutes the basic structure of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com