Broken strap seizing device for belt

A belt and conveying roller technology, applied in the field of belt-broken belt catching devices, can solve the problems of complex operating environment, small braking area, and malfunction, and achieve the effect of simple triggering principle, accurate signal, and rapid action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

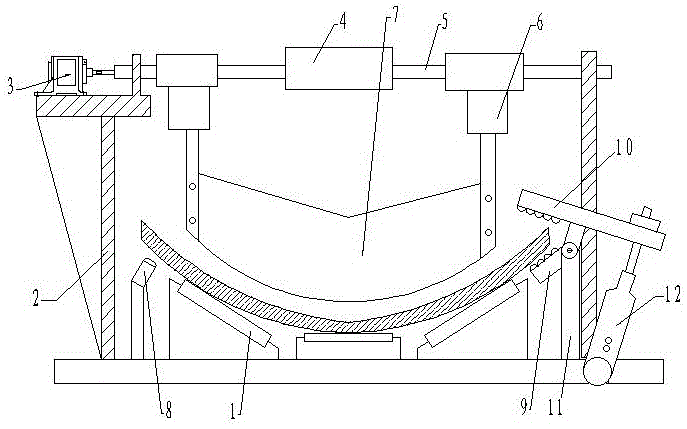

[0008] Such as figure 1 As shown, a broken belt arresting device, which includes a belt transmission drum frame 1, a frame-shaped support frame 2, a frequency conversion motor 3, a backstop 4, a transmission shaft 5, a telescopic cylinder 6, a coal shovel plate 7, a speed measuring Sensor 8, belt catching device, a speed measuring sensor 8 for measuring belt transmission speed change is fixed on one side of the belt transmission drum frame 1, and at least one belt catching device is fixed on the other end of the belt transmission drum frame 1, so Described belt capture device is made up of lower splint 9, upper splint 10, support 11 and oil cylinder 12, and support 11 is fixed on the belt conveying roller frame 1, and lower splint 9 is fixed on the upper end of support 11, and upper splint 10 is relative to lower splint 9. It is rotatably fixed on the bracket 11 through the rotating shaft, and the upper splint 10 is driven and rotated by the oil cylinder 12, wherein the clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com