A method for synthesizing neodymium phosphate solution and the synthesized neodymium phosphate solution

A neodymium phosphate solution technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of ineffective reduction of glue viscosity and single composition of neodymium phosphate solution, so as to improve processing performance and reduce glue viscosity , the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

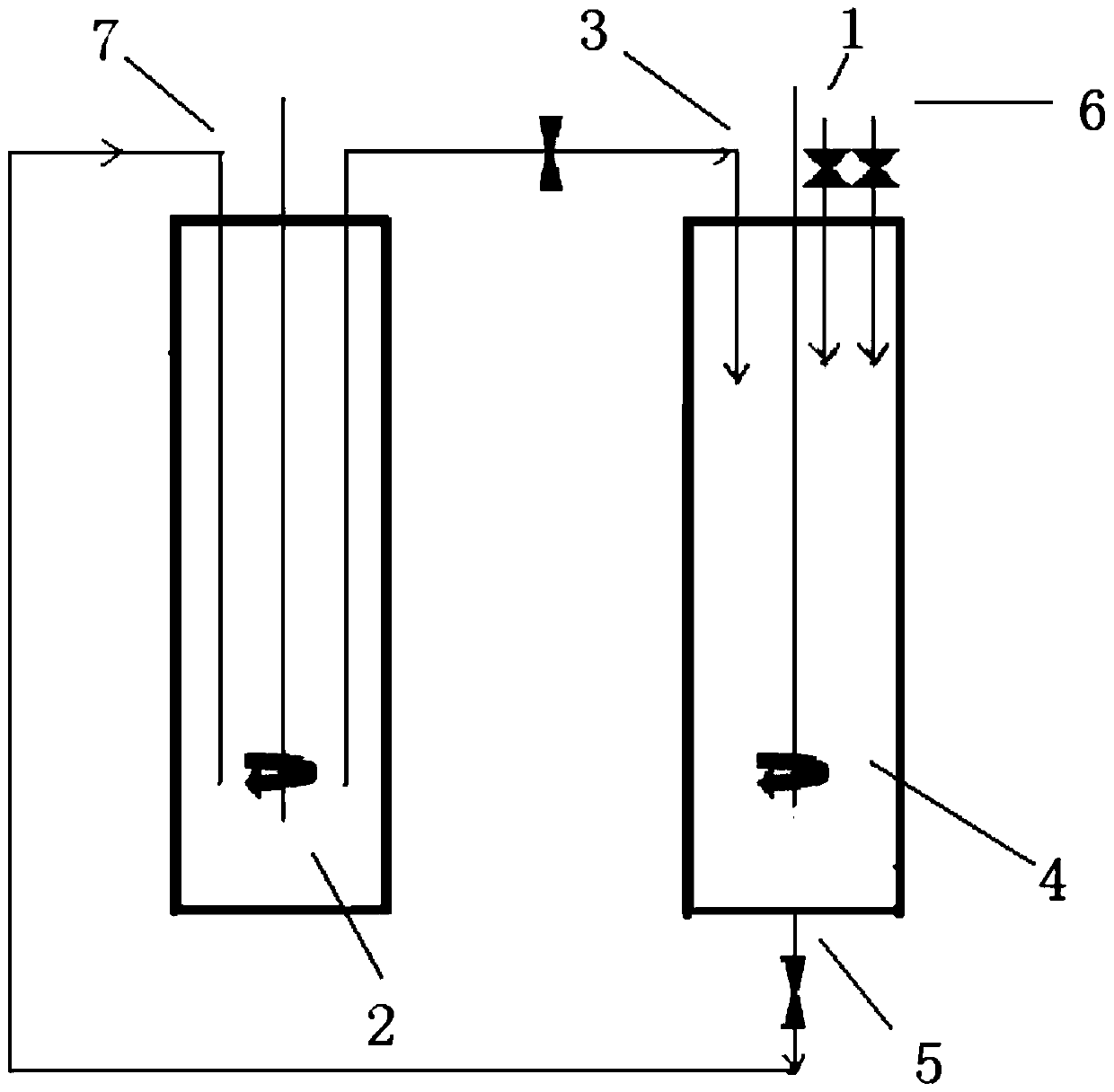

[0057] The present embodiment provides a method for synthesizing neodymium phosphate solution, which adopts figure 1 The production device shown is carried out, the method comprises the following steps:

[0058] 1, nickel chloride hexahydrate is prepared into saturated nickel chloride aqueous solution in nickel chloride solution kettle 2;

[0059] 2. Add 840kg of C6 oil to the reactor 4 through the first feeding port 1, then add 150kg of 2-ethylhexyl phosphate 2-ethylhexyl ester, 5kg of molecular sieves, and heat and stir for 5min;

[0060] 3. Add 25kg of neodymium oxide solid powder into the reactor 4 through the third feed port 6, and stir for 5min;

[0061] 4, the saturated nickel chloride aqueous solution in the nickel chloride solution kettle 2 is joined in the reactor 4 by the second feeding port 3 to react, the add-on of the saturated nickel chloride aqueous solution is 5L, and the temperature of reaction is controlled to be 35-50 ℃. ℃, the reaction time is controlled...

Embodiment 2

[0065] The present embodiment verifies its catalytic effect of saturated nickel chloride solution in the method for synthesizing neodymium phosphate solution in Example 1, and the verification test comprises the following steps:

[0066] 1. Add 840kg of C6 oil to the reactor 4 through the first feeding port 1, then add 150kg of 2-ethylhexyl phosphate 2-ethylhexyl ester, add 5kg of molecular sieves, and heat and stir for 5min;

[0067] 2. Add 25kg of neodymium oxide solid powder into the reactor 4 through the third feeding port 6, and stir for 5min; control the temperature of the mixed solution to 50-55°C, stir for 60min, and no reaction occurs in the neodymium oxide;

[0068] 3, nickel chloride hexahydrate is prepared into saturated nickel chloride aqueous solution in nickel chloride solution kettle 2;

[0069] 4, the saturated nickel chloride aqueous solution in the nickel chloride solution kettle 2 is added in the reactor 4 to react by the second feed port 3, and the add-on ...

Embodiment 3

[0073] The present embodiment provides a method for synthesizing neodymium phosphate solution, which adopts figure 1 The production device shown is carried out, the method comprises the following steps:

[0074] 1. The titanium chloride hexahydrate is prepared into a saturated titanium chloride aqueous solution in the titanium chloride solution kettle 2;

[0075] 2. Add 840kg of C6 oil to the reactor 4 through the first feeding port 1, then add 150kg of 2-ethylhexyl phosphate 2-ethylhexyl ester, 5kg of molecular sieves, and heat and stir for 5min;

[0076] 3. Add 25kg of neodymium oxide solid powder into the reactor 4 through the third feeding port 6, stir for 5min, control the temperature of the mixed solution to 20-50°C, stir for 60min, and no reaction occurs in the neodymium oxide;

[0077] 4. The saturated titanium chloride aqueous solution in the titanium chloride solution kettle 2 is added to the reaction kettle 4 to react through the second feed port 3, and the add-on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com