A kind of air mixing micro-electrolysis reactor and reaction method

A micro-electrolysis reactor and hybrid technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problems of easy hardening of fillers and reduced efficiency of sewage treatment, and avoid replacement , improve the reaction efficiency and sewage treatment efficiency, and avoid the effect of packing compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

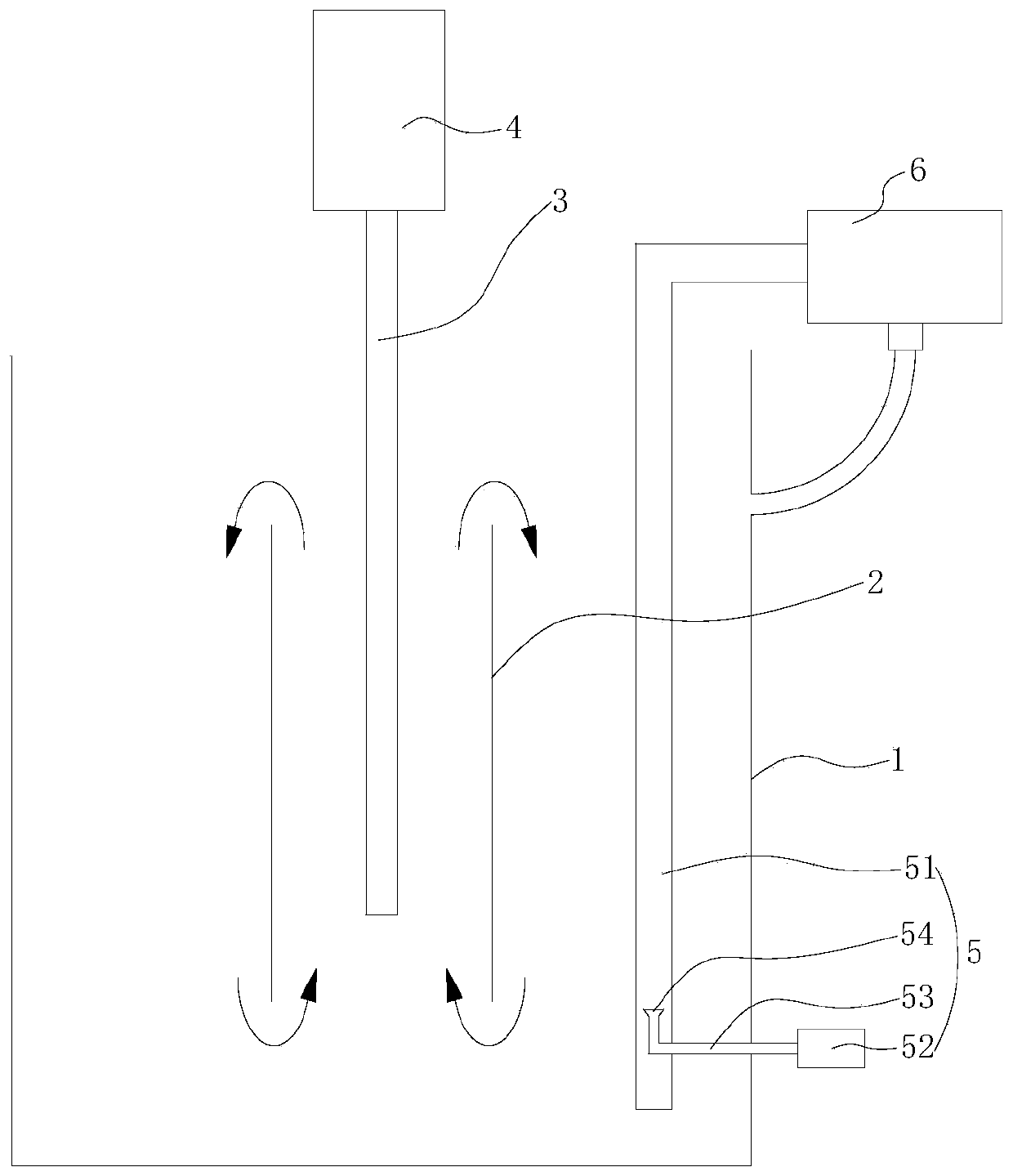

[0021] see figure 1 , the embodiment of the present invention provides a kind of air mixing type micro-electrolysis reactor, comprises,

[0022] Reactor 1;

[0023] A diversion cylinder 2, the diversion cylinder 2 is coaxially built into the reaction cylinder 1, the lower end of the diversion cylinder 2 forms a gap with the bottom of the reaction cylinder 1, and the upper end is lower than the sewage liquid level in the reaction cylinder 1 ;

[0024] A guide tube 3, the guide tube 3 is coaxially built into the guide tube 2, one end of the guide tube 3 extends downward to the lower end of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com