Flame retardant polyamide composition

A polyamide composition, flame retardant technology, applied in the field of flame retardant polyamide composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

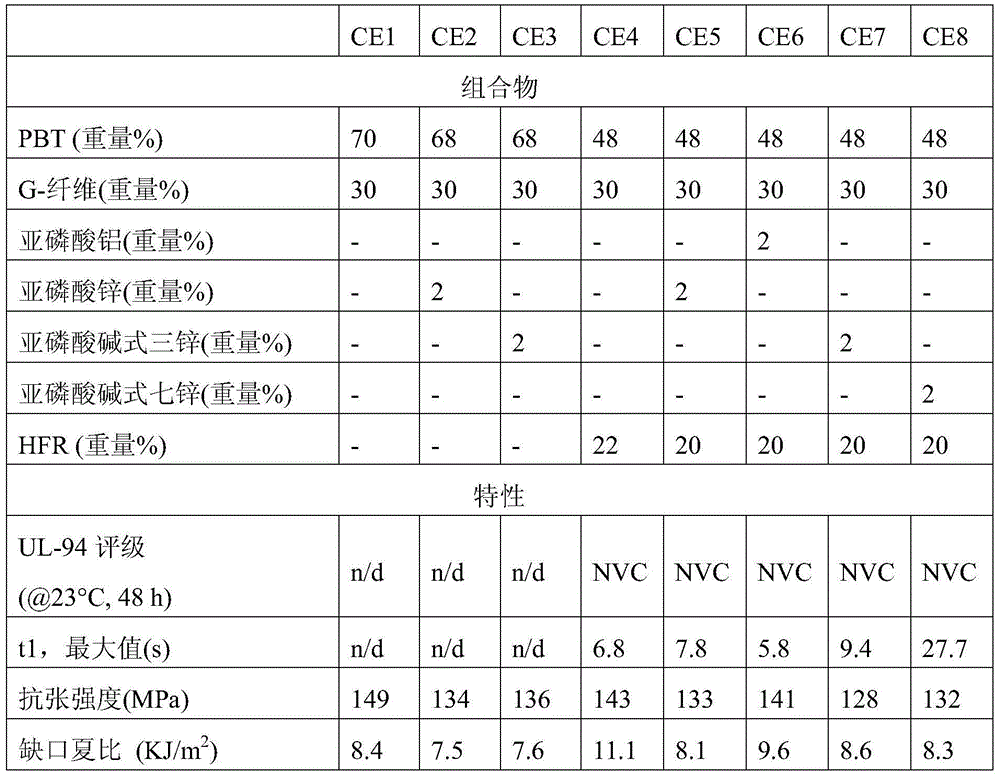

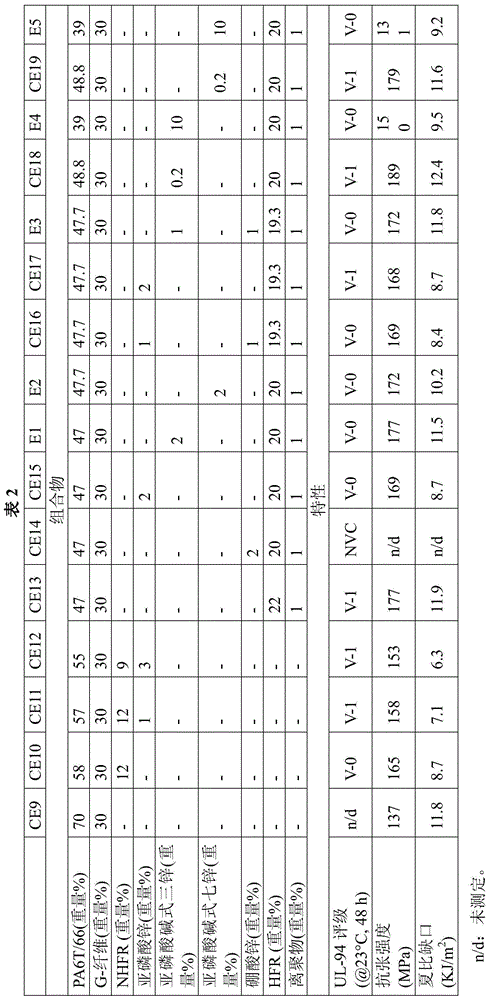

Examples

Embodiment

[0034] Material:

[0035] · PBT : purchased from Taiwan Chang Chun Plastics Co., Ltd. (Chang Chun Plastics Co., Ltd.) under the trade name LONGLITE TM Polybutylene terephthalate resin of 1200-211E;

[0036] · PA6T / 66 : purchased from the U.S. DuPont (E.I.du Pont de Nemours and Company) (hereinafter referred to as "DuPont") trade name Polyamide 6T, 66 resin of HTN502;

[0037] · G-fiber : glass fibers purchased from Nippon Electric Glass Co., Ltd. (Nippon Electric Glass Co., Ltd.) by the name ECS03 T-262H;

[0038] · NHFR (non-halogen flame retardant) : purchased from Switzerland Clariant company (Clariant) under the trade name Exolit TM Aluminum diethylphosphonite of OP1230;

[0039] · Aluminum phosphite : purchased from Japan Taiping Industry Co., Ltd. (Teihei Chemical Industry Co., Ltd.), trade name is APA-100;

[0040] · Zinc phosphite : ZnHPO purchased from Shanghai Guanghua Technology Co., Ltd., China 3 ;

[0041] · trizinc basic phosphite : 3ZnO Zn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com