Water washing machine with adjustable fabric expanding devices

A widening device and adjustable technology, applied in the field of textile printing and dyeing, can solve the problems of affecting the quality of the fabric, the fabric cannot be fully stretched, etc., and achieve the effect of improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

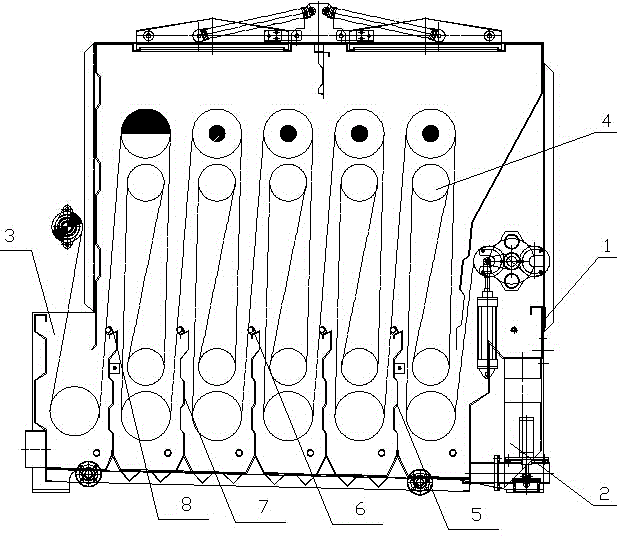

[0014] Such as figure 1 , 2 As shown in, 3, and 4, the present invention includes a washing box 1, which is provided with a cloth inlet 2 and a cloth outlet 3. In the washing box 1, there are multiple sets of cloth guide roller groups 4, and two adjacent groups of cloth guide A widening device 5 is provided between the roller groups 4.

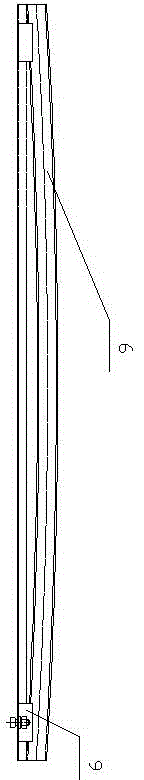

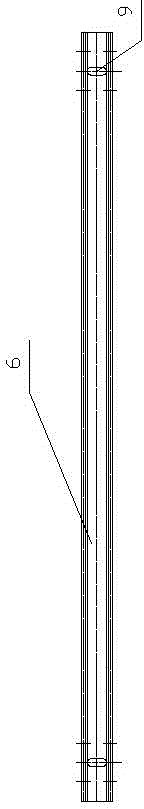

[0015] The expansion device 5 includes a micro-arc rod 6 and a bracket 7 supported at the bottom of the washing tank. The upper end of the bracket 7 is provided with an inclined flanging 8, the micro-arc rod 6 is a hollow body, and the upper end surface of the micro-arc rod 6 is an arc surface. The two ends of the lower end surface of the micro-arc rod 6 are respectively provided with waist-shaped grooves 9 along the width direction of the micro-arc rod. The waist-shaped grooves 9 at both ends of the lower end surface of the micro-arc rod 6 and the flange 8 at the upper end of the bracket 7 are connected by bolts 10. The arc-shaped surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com