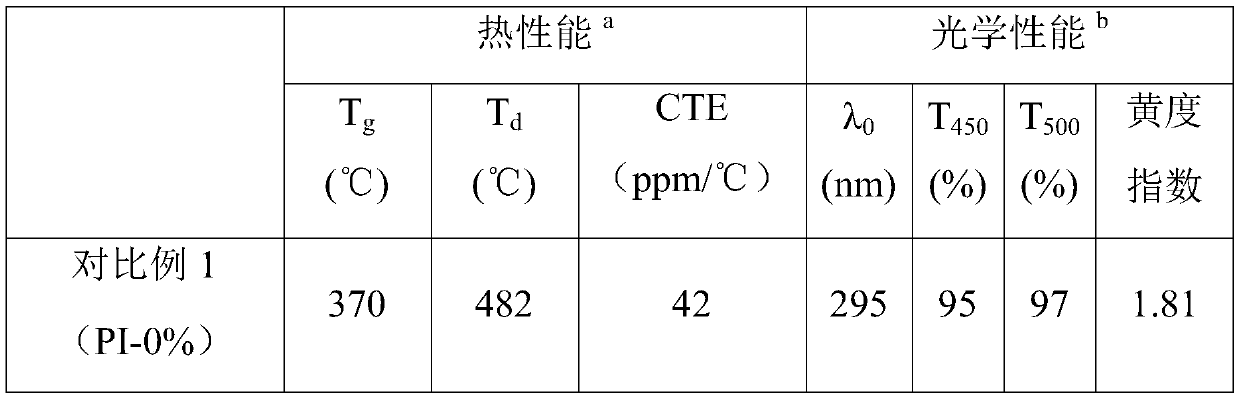

A kind of high transparent low expansion polyimide film and its preparation method and application

A technology of polyimide film and polyimide resin, which is applied in the field of high transparency and low expansion polyimide film and its preparation, can solve the problem that high light transmittance and low thermal expansion coefficient of polyimide film cannot have both. problems, to meet the requirements of device processing technology, improve light transmittance, and achieve significant effects of thermal expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1, the preparation of polyimide hybrid film PIPH-5% (doping amount 5wt%)

[0053] (1) Synthetic polyimide resin

[0054] For the synthesis steps and conditions of the polyimide resin, refer to the relevant part of Comparative Example 1.

[0055] (2) Doped perhydropolysilazane

[0056] In a three-neck flask equipped with a mechanical stirrer and a thermometer, add a perhydropolysilazane / dichloromethane solution with a solid content of 20 wt%, vacuum and depressurize at 50°C, and slowly remove the solvent dichloromethane until a colorless Transparent viscous liquid or solid. Take the perhydropolysilazane and the polyimide resin prepared in step (1), and dissolve them in N-methylpyrrolidone (NMP) to obtain organic solutions with solid contents of 5 wt% and 20 wt%, respectively. Take 2.24 grams of the above-prepared perhydropolysilazane solution, slowly add it to 10.64 grams of polyimide solution, stir and mix rapidly at room temperature, and defoam under vacu...

Embodiment 2

[0059] Embodiment 2, the preparation of polyimide hybrid film PIPH-10% (doping amount 10wt%)

[0060] (1) Synthetic polyimide resin

[0061] For the synthesis steps and conditions of the polyimide resin, refer to the relevant part of Comparative Example 1.

[0062] (2) Doped perhydropolysilazane

[0063] In a three-neck flask equipped with a mechanical stirrer and a thermometer, add a perhydropolysilazane / dichloromethane solution with a solid content of 30% by weight, vacuum and reduce pressure at 40°C, and slowly remove the solvent dichloromethane until a colorless Transparent viscous liquid or solid. Take perhydropolysilazane and the polyimide resin prepared in step (1), and dissolve them in N,N-dimethylacetamide (DMAc) respectively to prepare organic solutions with solid contents of 5wt% and 15wt%. Take 5 grams of the above-prepared perhydropolysilazane solution, slowly add it to 15 grams of polyimide solution, stir and mix rapidly at room temperature, and defoam under v...

Embodiment 3

[0066] Embodiment 3, the preparation of polyimide hybrid film PIPH-15% (doping amount 15wt%)

[0067] (1) Synthetic polyimide resin

[0068] For the synthesis steps and conditions of the polyimide resin, refer to the relevant part of Comparative Example 1.

[0069] (2) Doped perhydropolysilazane

[0070] In a three-neck flask equipped with mechanical stirring and a thermometer, add a perhydropolysilazane / dichloromethane solution with a solid content of 15% by weight, vacuum and reduce pressure at 50°C, and slowly remove the solvent dichloromethane until a colorless Transparent viscous liquid or solid. Take the perhydropolysilazane and the polyimide resin prepared in step (1), and dissolve them in N-methylpyrrolidone (NMP) to obtain organic solutions with solid contents of 4 wt% and 25 wt%, respectively. Take 10 grams of the above-prepared perhydropolysilazane solution, slowly add it to 9.07 grams of polyimide solution, stir and mix rapidly at room temperature, and defoam un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| yellowness index | aaaaa | aaaaa |

| yellowness index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com