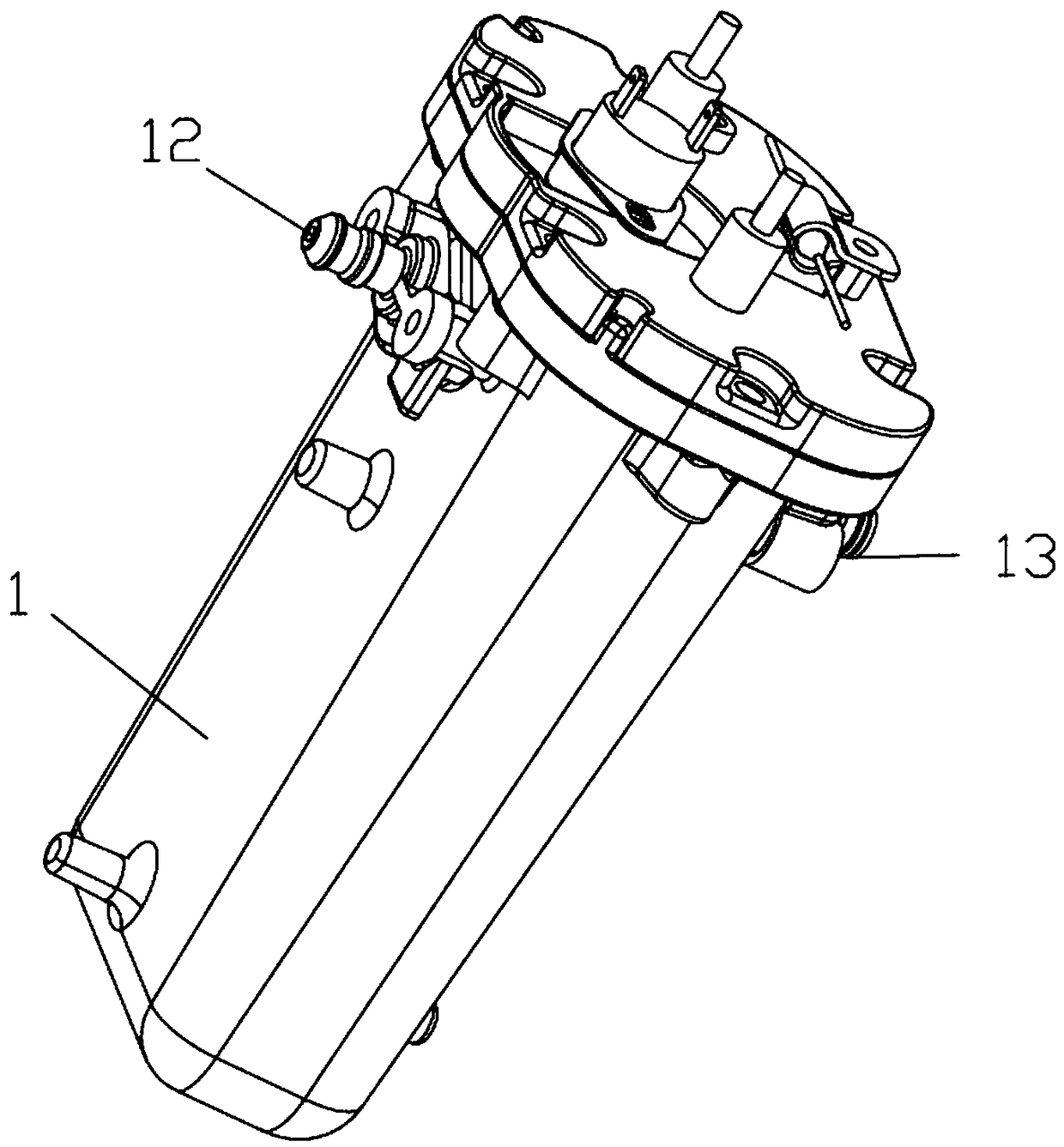

A heating pot component

A heating pot and component technology, applied in textiles and papermaking, finishing utensils, washing devices, etc., can solve the problems of weak steam, small water pump flow, and small steam volume, so as to improve steam formation efficiency and increase water flow path , Improve the effect of dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

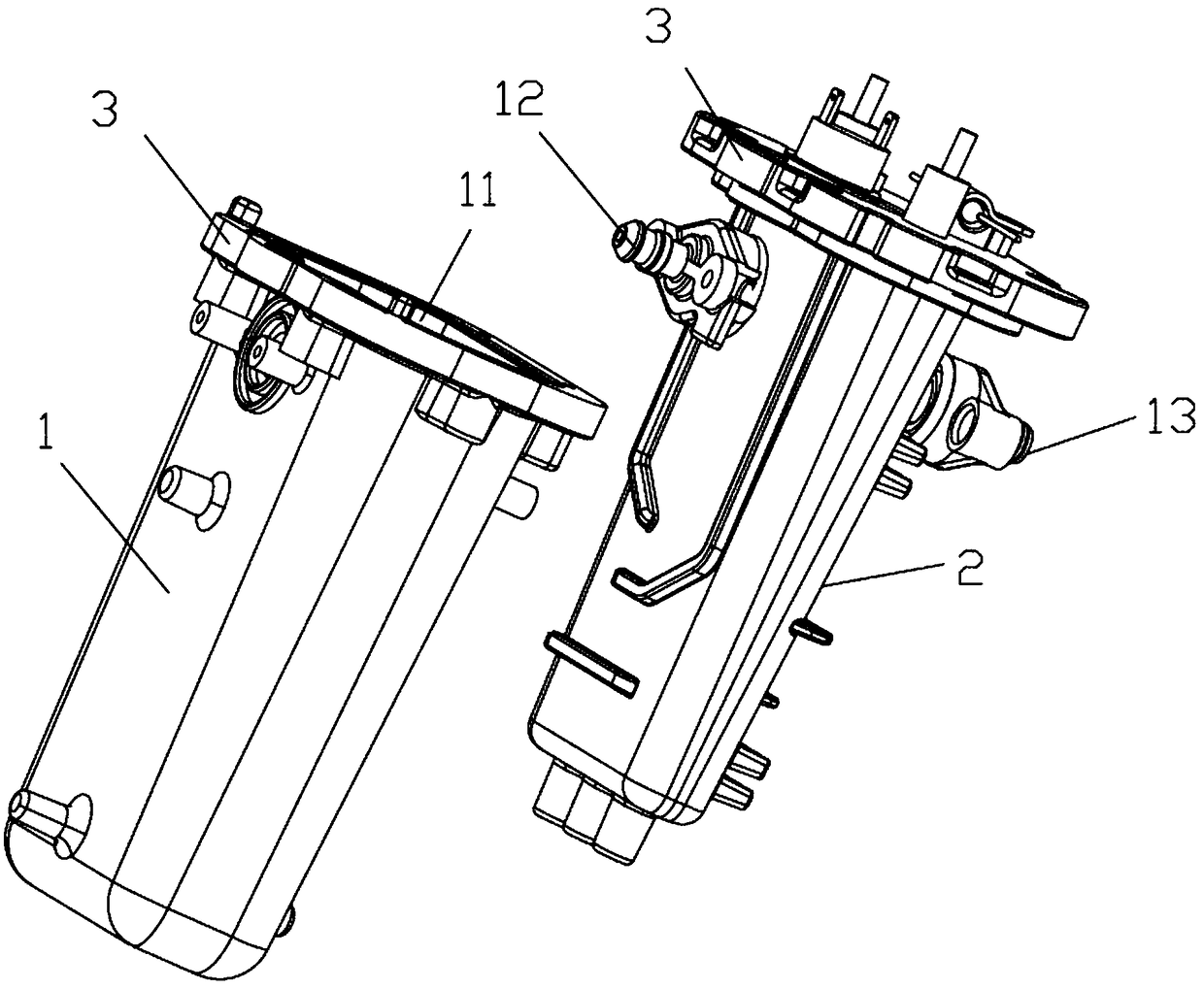

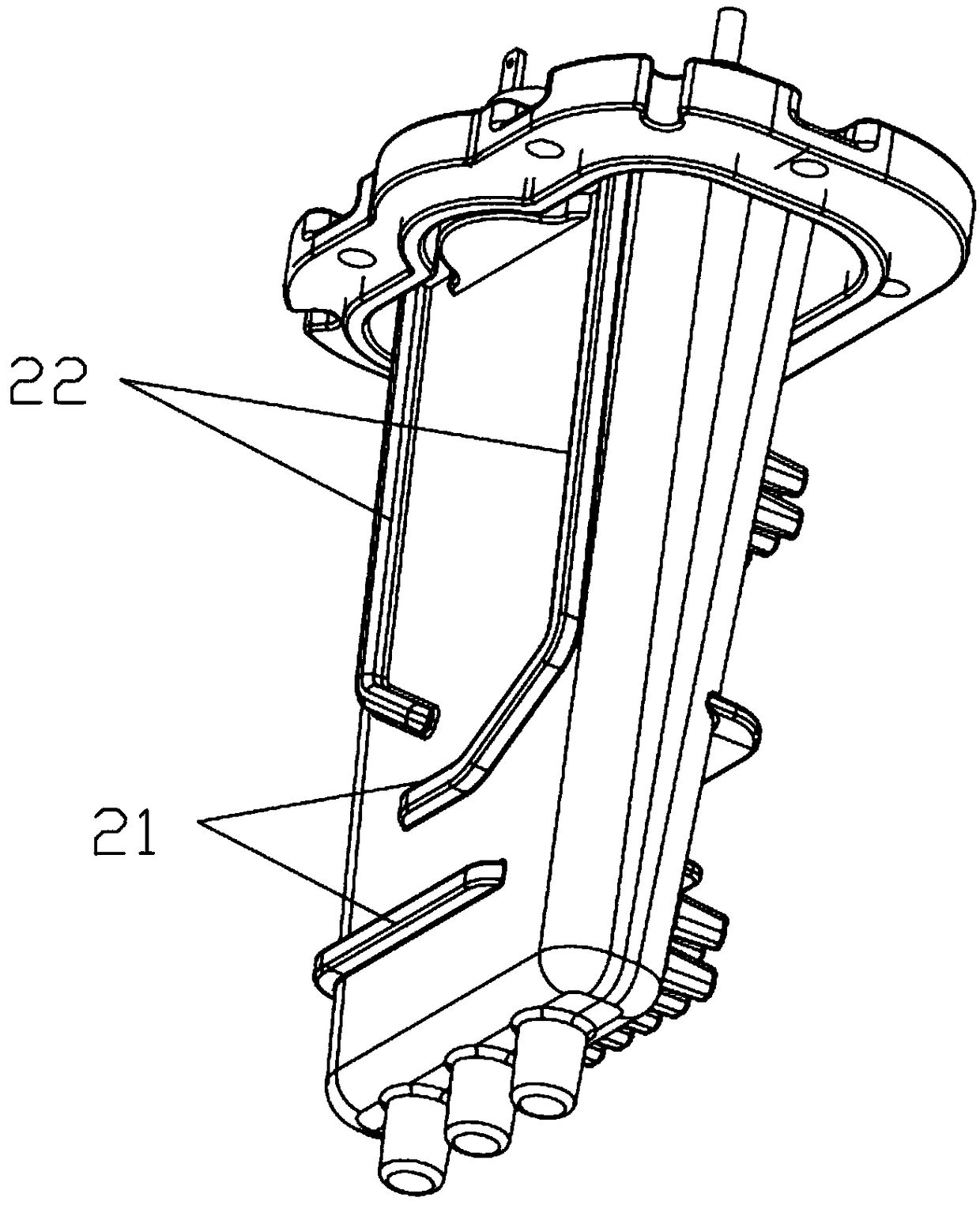

[0032] In the prior art, steam heaters used in garment steamers are usually of a single-inlet and single-outlet coil structure. The flow rate of the water pump of the heating element in this structure is relatively small. Once the flow rate of the water pump increases, the heater has no time to heat the water. If it turns into steam, water will be sprayed from the outlet of the heating element, resulting in low dryness of the steam.

[0033] Aiming at the deficiencies in the prior art, the present invention provides a heating pot assembly. The heating tank is formed with several baffles on the water inlet side, and the water flow path is effectively increased by setting the baffles, so that the water flows into the assembly. The entire path to the exhaust steam is lengthened, so that the steam can be heated to the maximum and the dryness of the steam can be improved.

[0034] The technical solutions of the present invention will be clearly and completely described below throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com