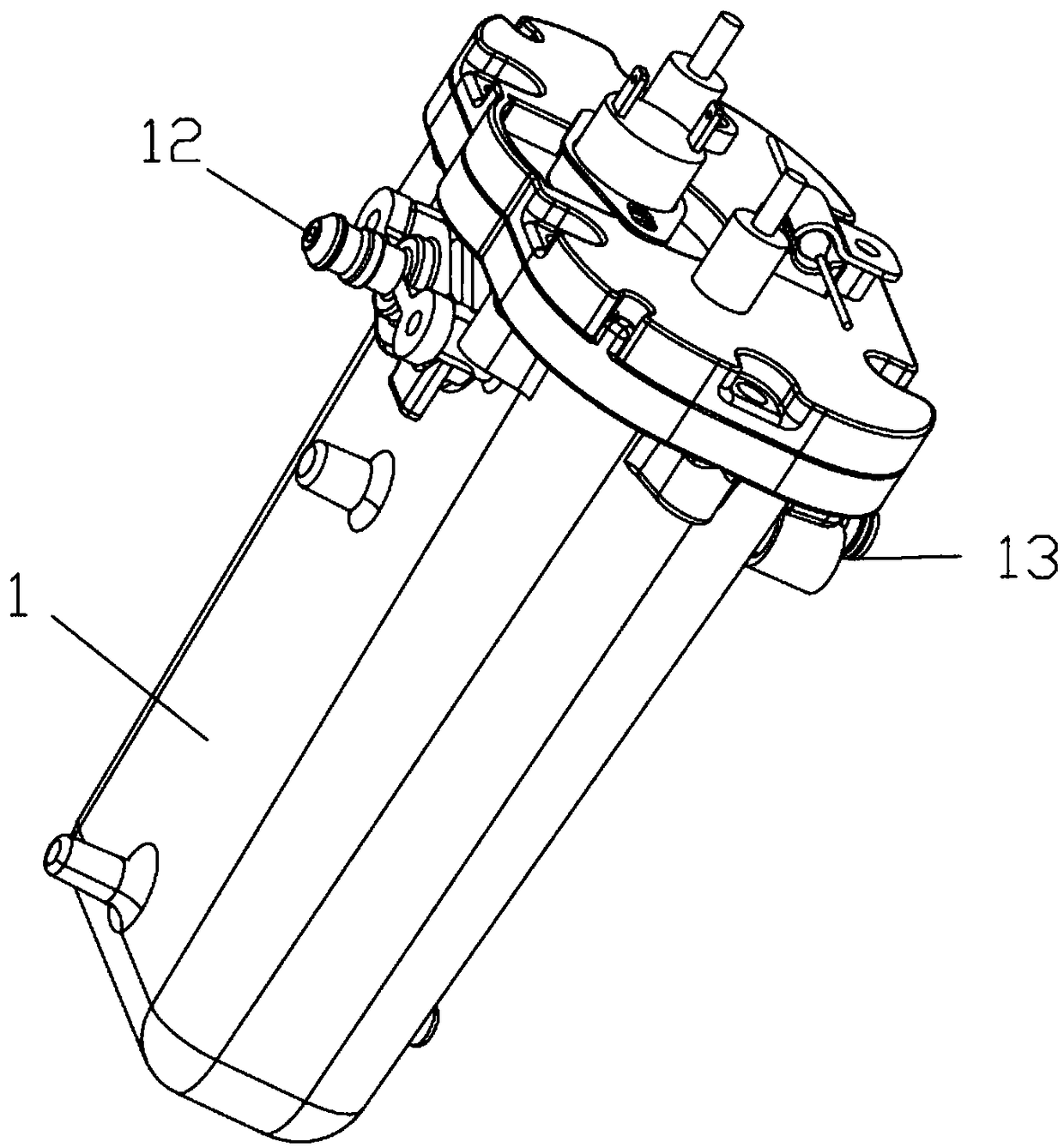

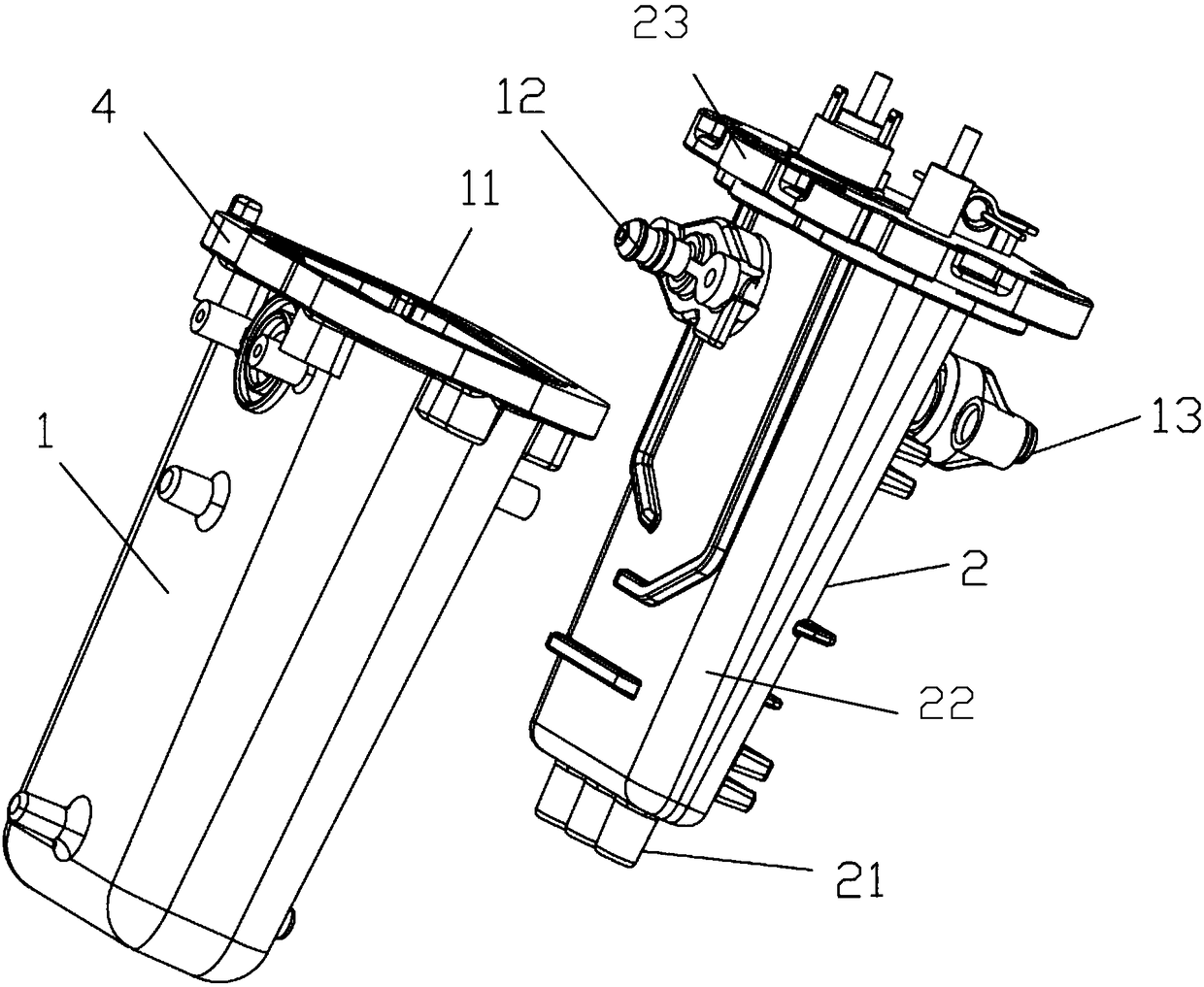

A heating pot assembly

A heating pot and component technology, which is applied in the direction of steam generation, steam generation method, lighting and heating equipment, etc., can solve the problems of weak steam, low steam dryness, and small amount of steam, so as to improve the efficiency of steam formation and avoid internal The effect of accumulating water and improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

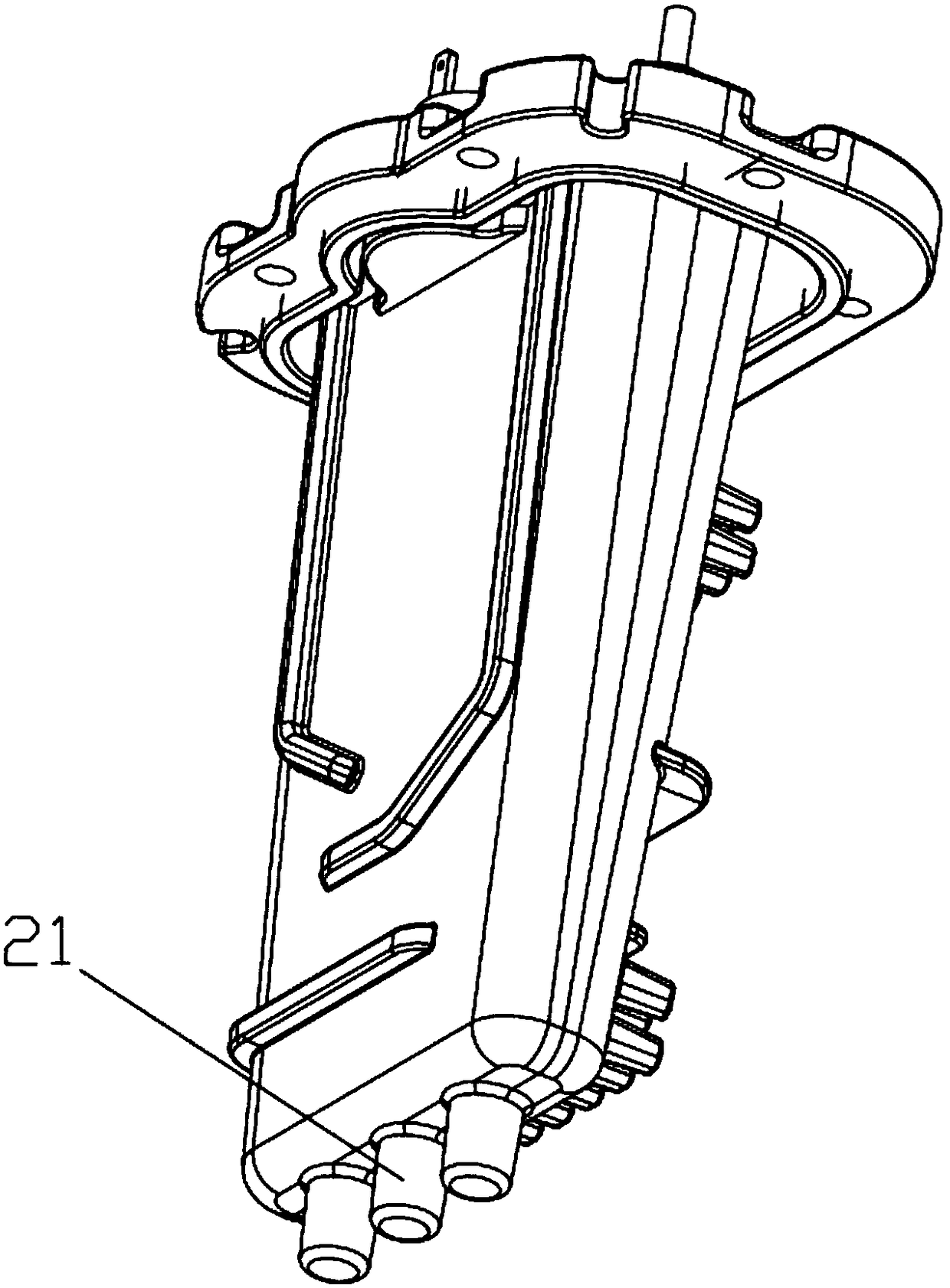

[0032] In the prior art, the steam heating device used for garment ironing machines is usually a single-inlet and single-outlet coil structure. The flow rate of the water pump of the heating element in this structure is relatively small. Once the flow rate of the water pump increases, the heating element has no time to heat the water. If it turns into steam, water will be sprayed from the outlet of the heating element, resulting in low dryness of the steam.

[0033] Aiming at the deficiencies in the prior art, the present invention provides a heating pot assembly. By adopting the casing and the heating liner which are nested in each other, the heating liner can complete the evaporation of the water entering the heating pot and discharge it through the upper air outlet. Effectively increase the steam output, maximize the heating of the steam, avoid the problem of water spraying at the air outlet, and improve the dryness of the steam.

[0034] The technical solutions of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com