Fully-assembled plate column structure and fully-assembly floor system composed of same

A technology for assembling slab and column structures, applied in the direction of floor slabs, building components, building structures, etc., can solve problems such as stress concentration of beam-column joints, and achieve the effects of stress dispersion, cost reduction, and construction period shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

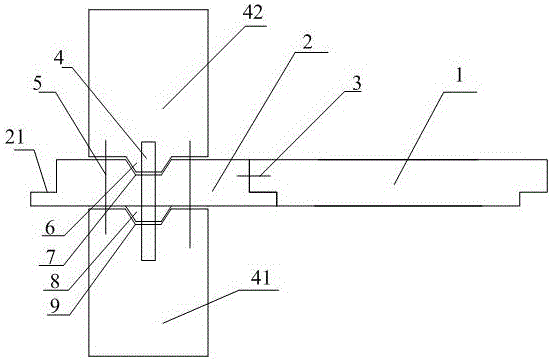

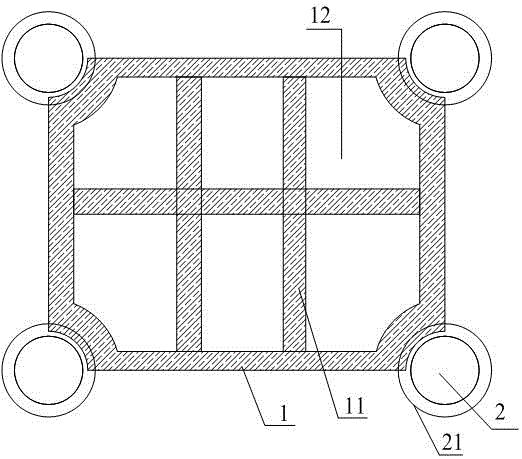

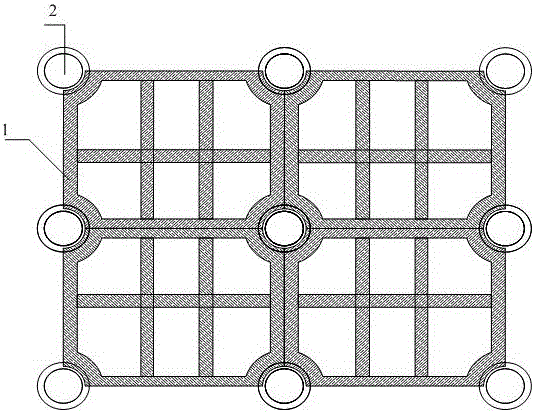

[0025] Such as Figure 1-Figure 2 as shown,

[0026] Fully assembled slab-column structure, including a support column structure, the support column structure includes a column cap 2 located between the upper column 41 and the lower column 42, the column cap 2 is a fan-shaped structure, and the arc-shaped outer wall of the column cap extends outward to form a brim 21, also includes the floor, any corner of the floor is concaved into an arc-shaped corner, and one corner of the floor is lapped on the brim 21 so that the arc-shaped corner of the floor matches the arc-shaped outer wall of the column cap 2. This technical solution adopts the design principle of direct lapping between the column cap structure and the floor slab, uses the column cap structure and uses the brim set by the column cap structure as a supporting structure, the floor is directly erected on the eaves, and uses the column cap 2 as a fan-shaped structure or a circular structure The particularity of the hat b...

Embodiment 2

[0029] The difference between this embodiment and embodiment 1 is:

[0030] The column cap 2 is a quarter-circle fan-shaped structure, and the brim 21 is also a quarter-circle fan-shaped structure.

Embodiment 3

[0032] The difference between this embodiment and embodiment 1 is:

[0033] The column cap 2 is a fan-shaped structure of a half circle, and the brim 21 is also a fan-shaped structure of a half circle.

[0034] Example 3

[0035] The difference between this embodiment and embodiment 1 is:

[0036] The column cap 2 has a semicircular fan-shaped structure, and the brim 21 also has a semicircular fan-shaped structure.

[0037] Example 3

[0038] The difference between this embodiment and embodiment 1 is:

[0039] The column cap 2 has a circular structure, and the brim 21 also has a circular structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com