A quick installation nut

A nut, fast technology, applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve problems such as inability to quickly install and remove nuts, inability to quickly install and remove, and long strokes for nuts to be screwed in and out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

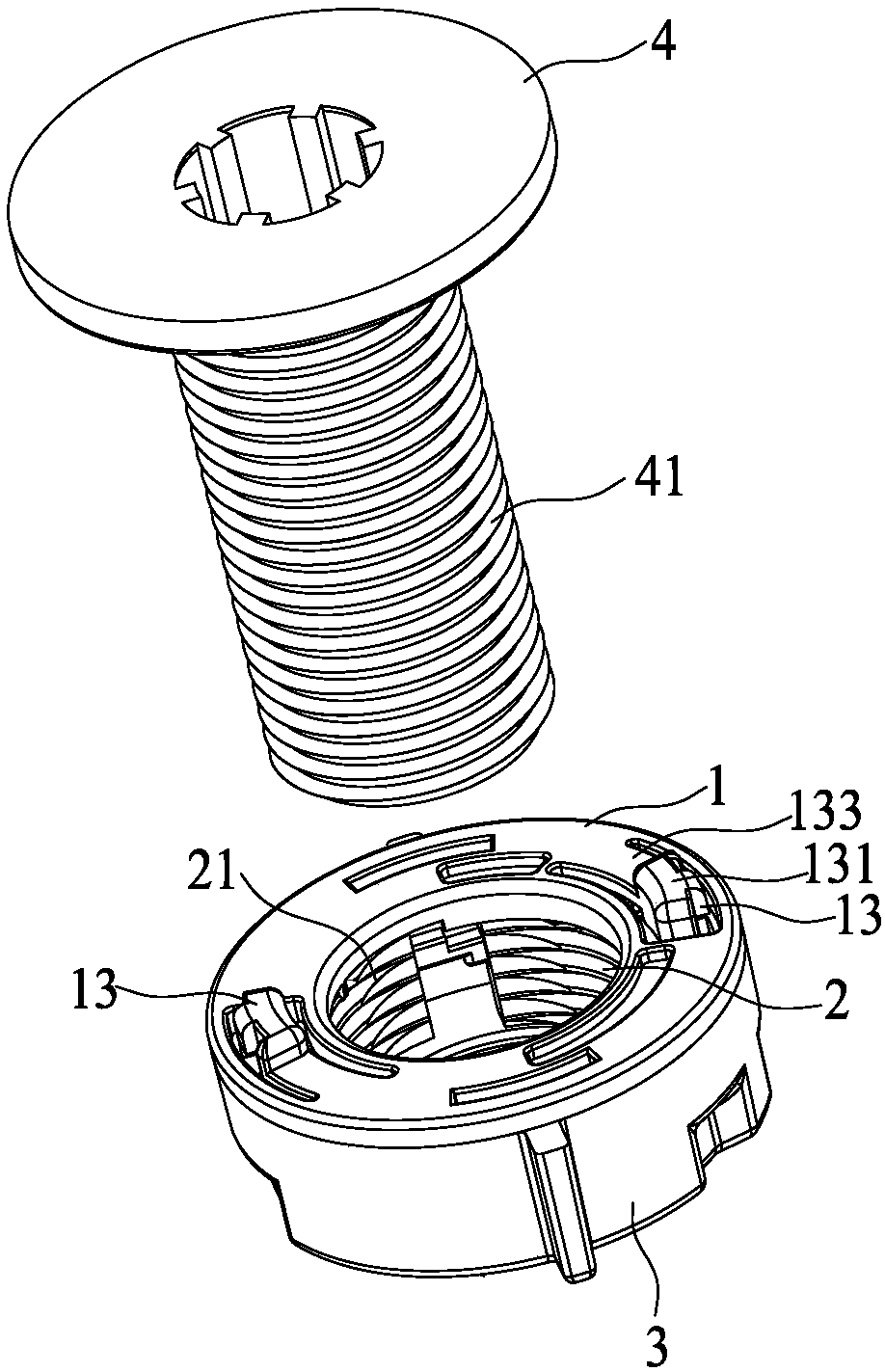

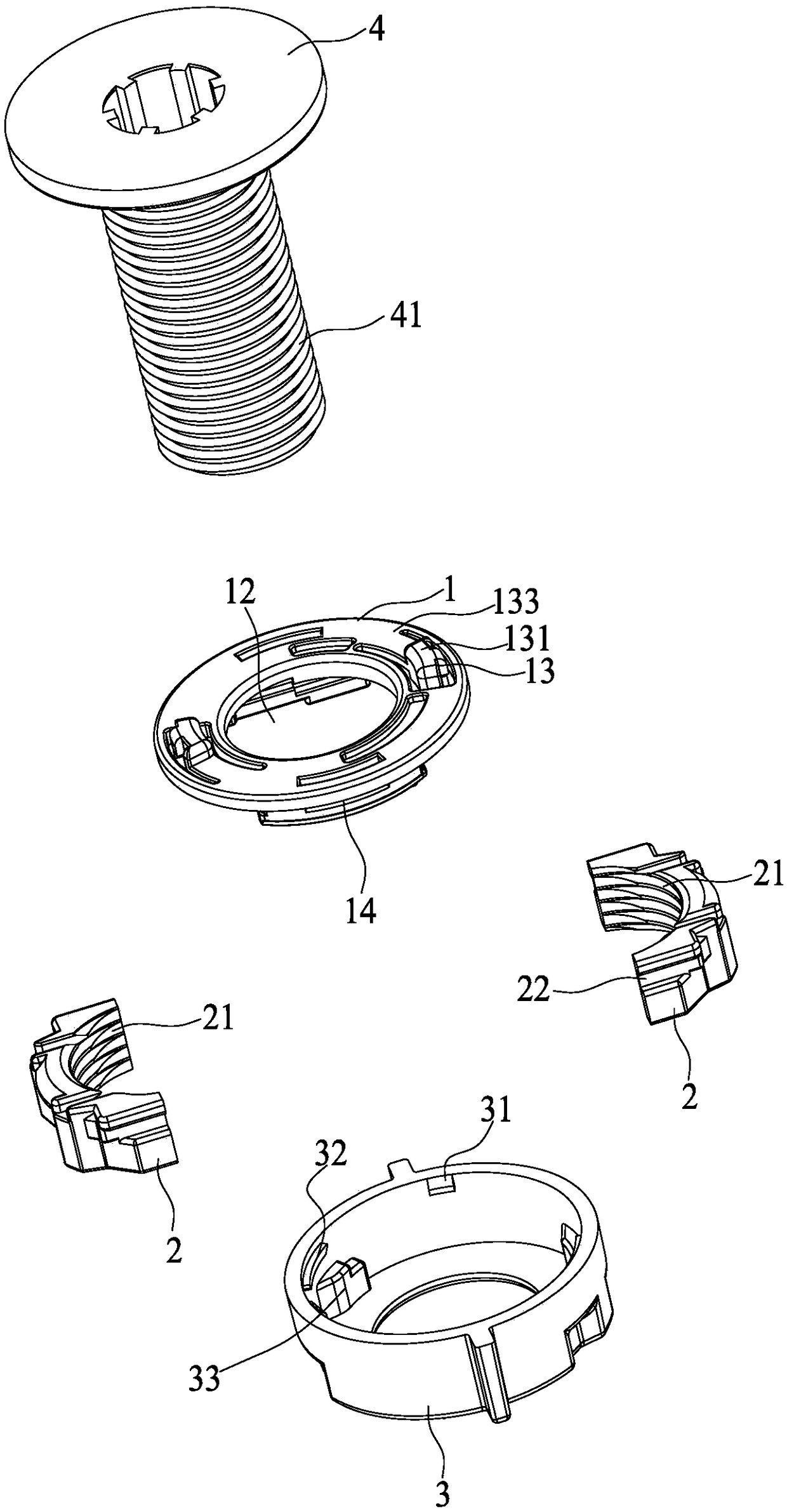

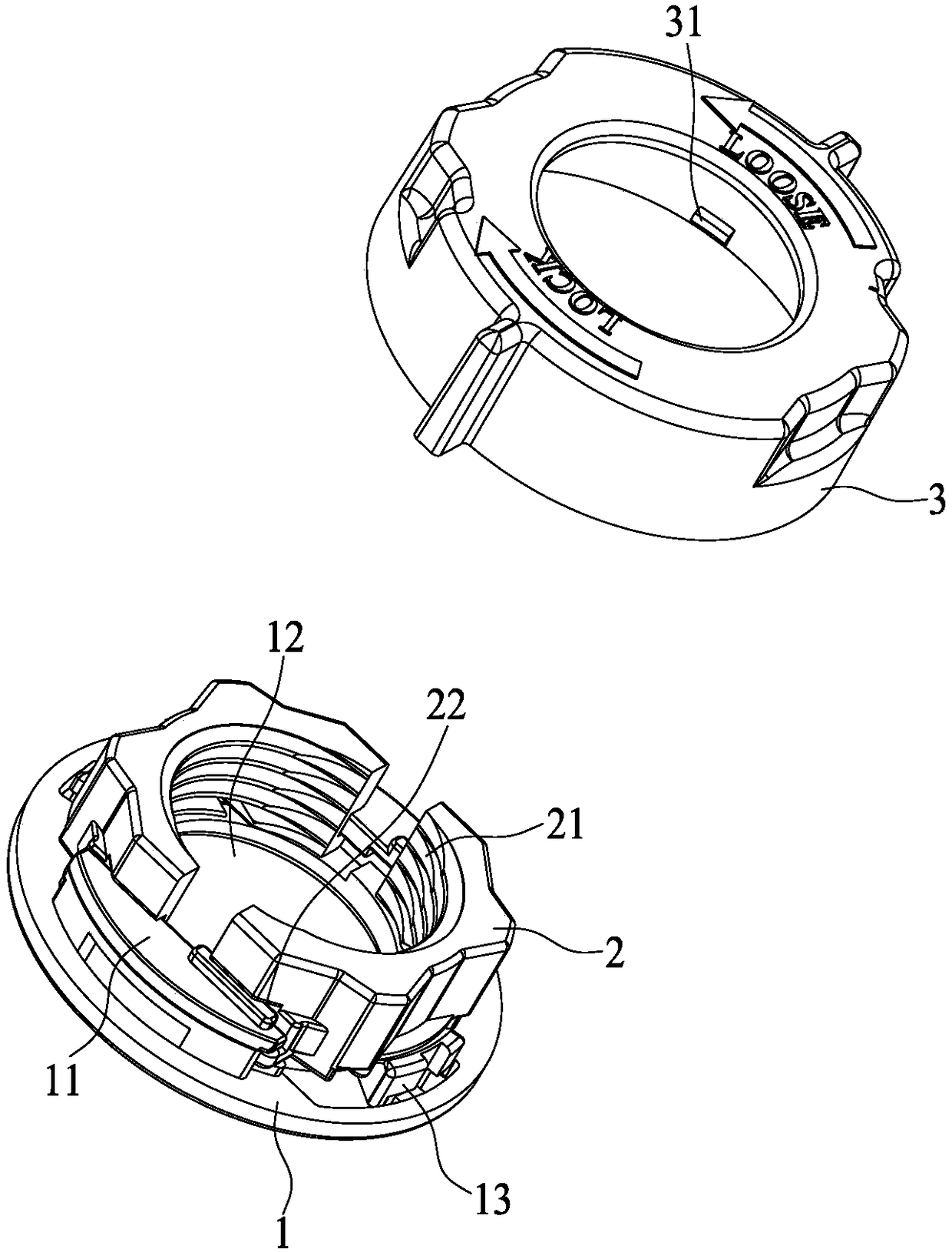

[0046] see Figure 1 to Figure 11 As described in a, a quick installation nut disclosed in the present invention includes a sliding seat 1 and at least two screw thread sliders 2 .

[0047] The at least two threaded sliders 2 are provided with internal threads 21 respectively, and the at least two threaded sliders 2 are slidably arranged relative to the sliding seat 2. In this embodiment, the threaded sliders 2 are slidably arranged through the cooperation of the slider and the chute. on carriage 1. Such as image 3 and Figure 4 As shown, a chute 22 is provided on the screw slider 2 , and a slider 11 is correspondingly provided on the slider 1 , and the slider 11 of the slider 1 slides in the chute 22 of the screw slider 2 .

[0048] A socket 12 is arranged on the sliding seat 1, and the socket 12 is convenient to be socketed with a scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com