Fixed point thickness measurement device for petroleum pipeline

A technology for oil pipelines and thickness measurement, which is used in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., and can solve problems such as the influence of ultrasonic thickness measurement devices on detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

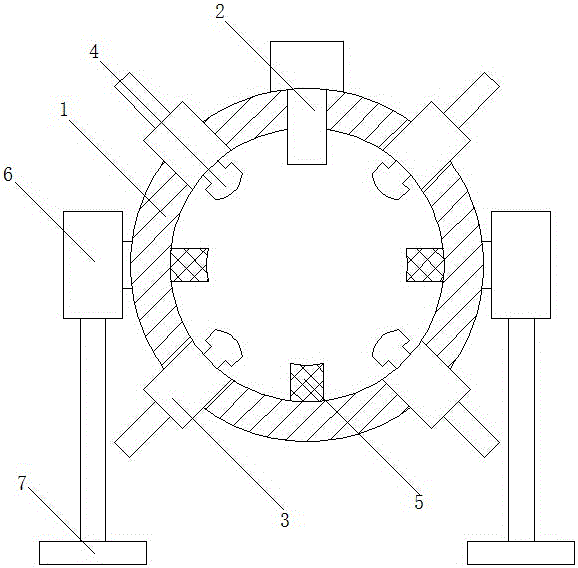

[0014] Such as figure 1 A fixed-point thickness measuring device for oil pipelines shown includes a detection bracket 1, and an ultrasonic thickness measurement device 2 is arranged on the detection bracket 1; a plurality of percussion cylinders 3 are arranged on the detection bracket 1, which respectively Extending along the radial direction of the oil pipeline, each knocking cylinder 3 is provided with a knocking end body 4 at the end.

[0015] As an improvement of the present invention, the detection bracket 1 adopts a ring structure extending circumferentially along the oil pipeline, and a plurality of support end bodies 5 are arranged on the inner wall of the detection bracket 1, which respectively extend along the radial direction of the detection bracket 1. Extending, each supporting end body 5 adopts an arc-shaped structure attached to the end surface of the oil pipeline relative to the end surface of the oil pipeline. Adopting the above-mentioned technical scheme, it...

Embodiment 2

[0019] As an improvement of the present invention, the two sides of the detection bracket 1 are respectively provided with support end frames, and each support end frame all includes an electric screw rod 6 fixed on the detection bracket, and the bottom end of the electric screw rod 6 The upper part is provided with a supporting base 7 extending above the horizontal direction. By adopting the above technical scheme, the detection bracket can be fixed on the ground through the setting of the support end frame, so that the position stability of the detection bracket together with the ultrasonic thickness measuring device and other devices can be further improved; at the same time, the support end frame The electric screw rod provided in it can make it adjust the height according to the position of the pipeline, so that the applicability of the oil pipeline fixed-point thickness measuring device in the present application can be improved.

[0020] The remaining features and advan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com