Optimization method of overhead weapon station structure based on improved kriging algorithm

An overhead weapon station and optimization method technology, applied in the field of structure optimization of an overhead weapon station, can solve the problems of large muzzle disturbance affecting shooting accuracy, etc., and achieve the effect of small muzzle disturbance and maximum muzzle disturbance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

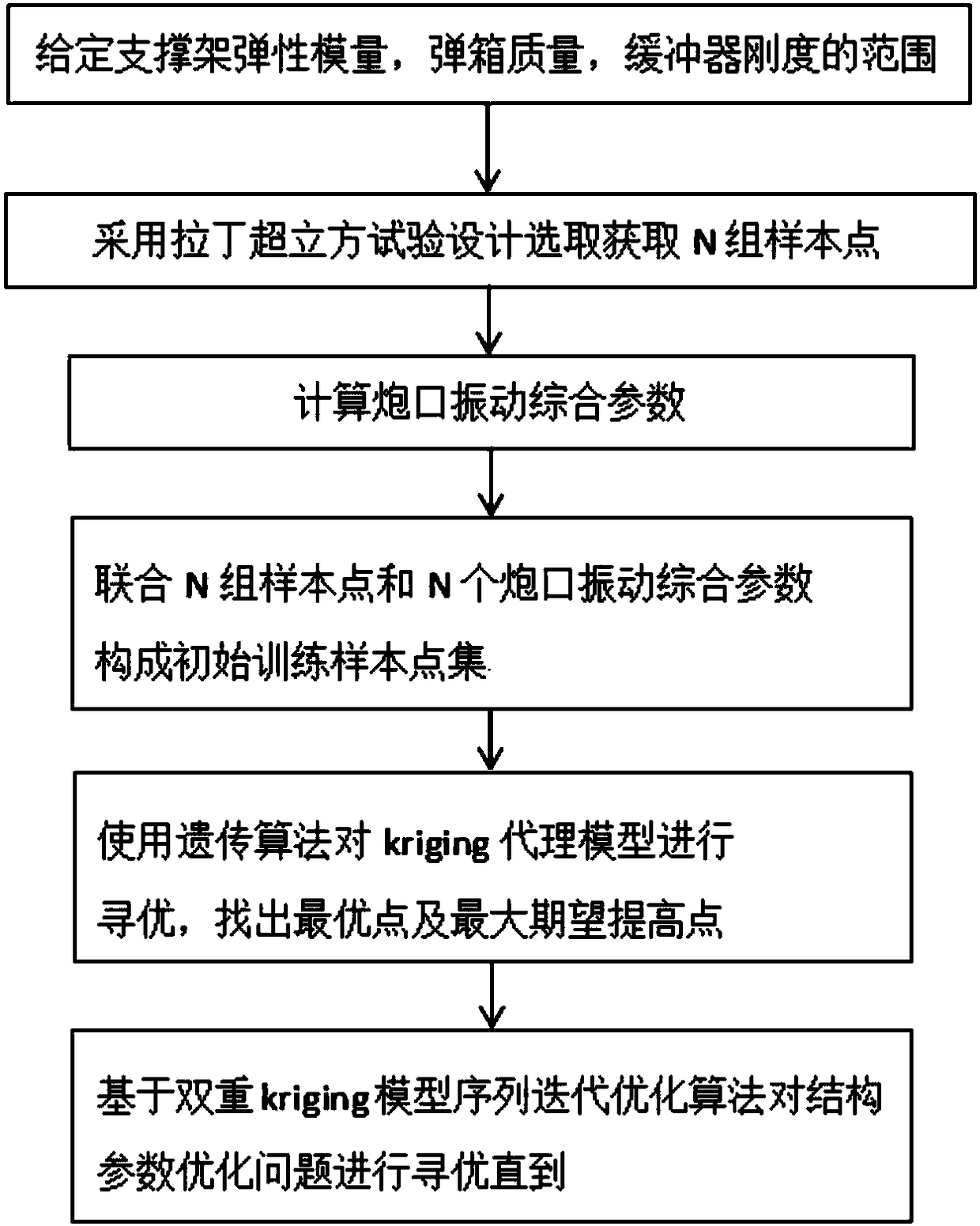

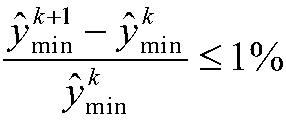

[0026] Such as figure 1 As shown, the present invention provides a method for optimizing the structure of the overhead weapon station based on the improved Kriging algorithm, comprising the following steps:

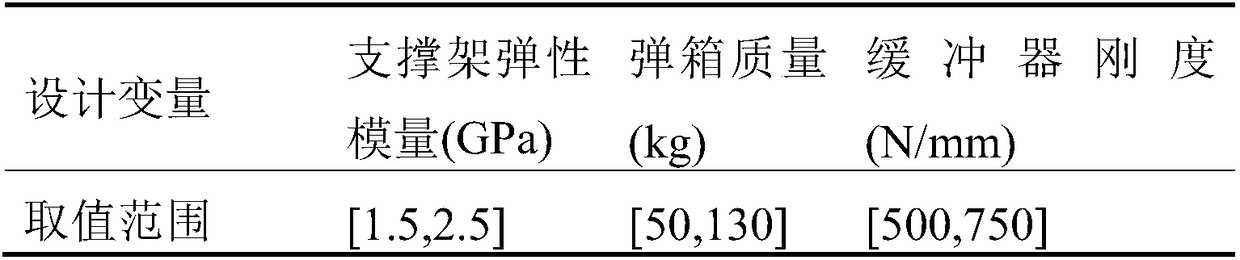

[0027] Step 1: Select the three structural parameters of the elastic modulus E of the support frame, the mass of the bullet box m, and the stiffness of the buffer K as the design variables of the optimization problem. The value ranges of these three parameters are shown in Table 1:

[0028] Table 1

[0029]

[0030] Step 2: Use the Latin hypercube design to select the values of E, m, and K, and obtain 35 sets of sample points (E i ,m i , K i ), i=1,2,...,35.

[0031] Step 3. Set the elastic modulus of the support frame of the overhead weapon station, the mass o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com