Vibration circular disc type no-tillage anti-blocking device

A disc-type, anti-blocking technology, which is applied to fertilization devices, seeding, planter parts, etc., can solve the problems of driving anti-blocking devices such as high noise, poor safety performance, and poor soil penetration ability, and achieves small soil disturbance and cutting Strong capacity and low soil disturbance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

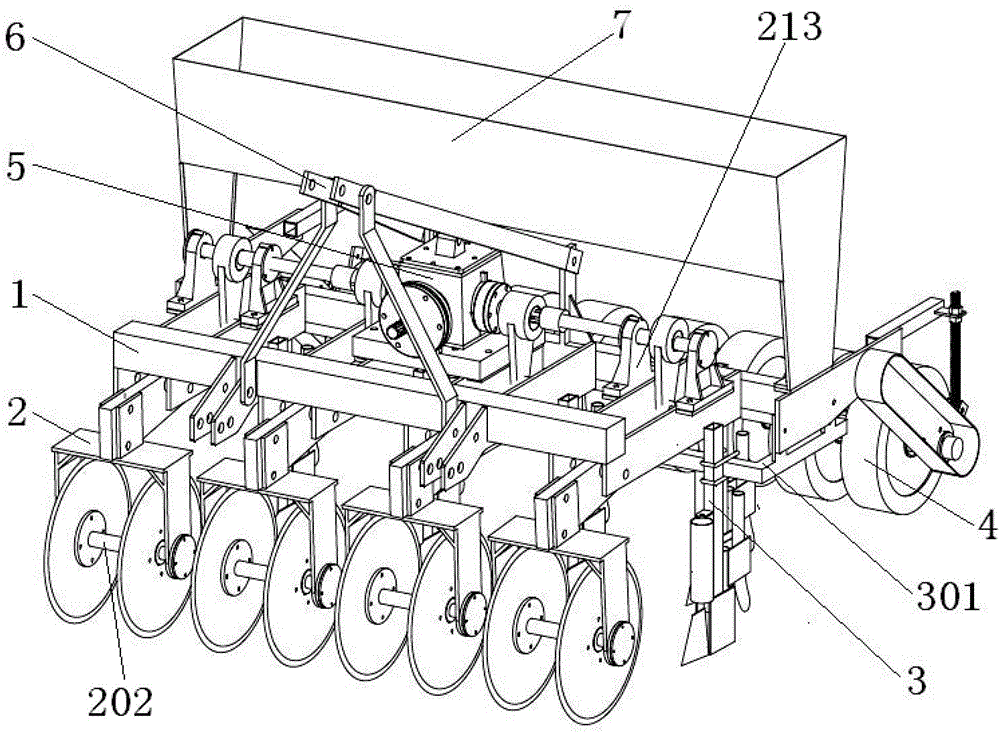

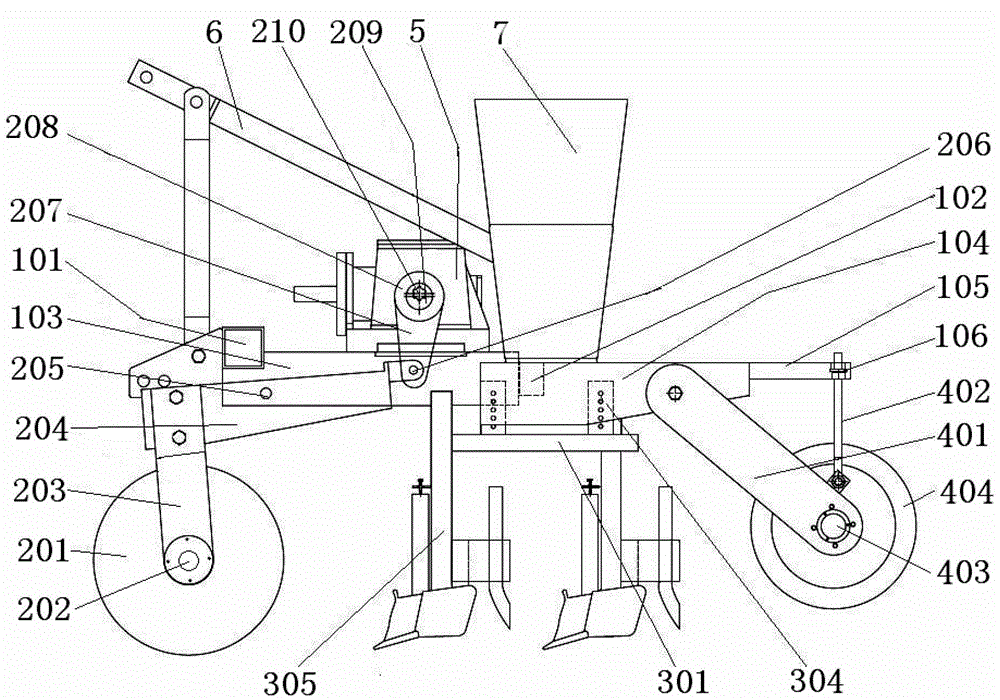

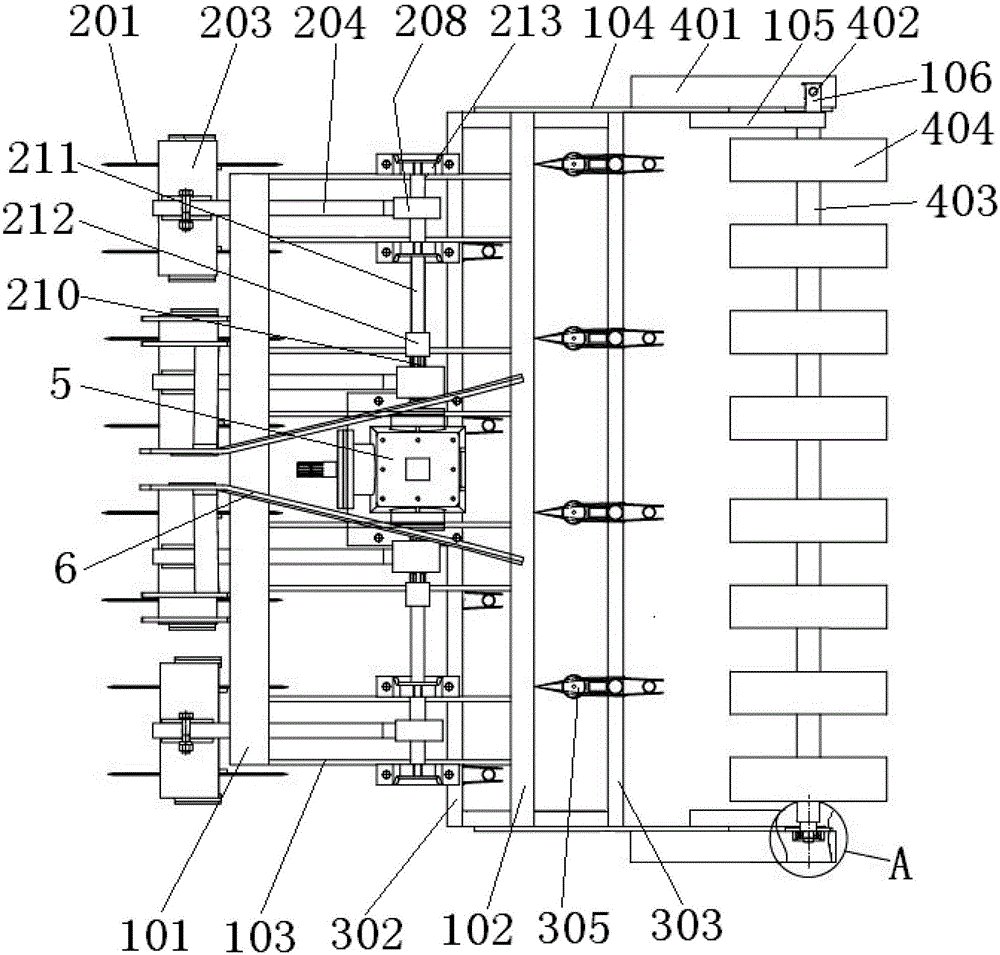

[0024] figure 1 It is a three-dimensional schematic diagram of a vibrating disc type no-tillage anti-blocking device used in a no-tillage planter embodiment. The vibrating disc type no-tillage anti-blocking device includes a frame 1, an anti-blocking device 2 and a gearbox 5. The vibrating disc type The no-tillage anti-blocking device is installed with a ditching device 3, a suppression mechanism 4 and a fertilizer box 7 to form a no-tillage seeder drawn by a tractor and powered. figure 2 and image 3 They are the schematic diagram of the front view and the schematic diagram of the top view of the vibrating disc type no-tillage anti-blocking device, respectively.

[0025] Such as Figure 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com