Method and system for dynamic fault simulation of double-section type catalytic cracking reaction-regeneralion system

A catalytic cracking and dynamic simulation technology, applied in the field of dual-stage catalytic cracking anti-regeneration system fault dynamic simulation method and system, can solve the problem of being unable to study and obtain system fault information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0164] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific processes.

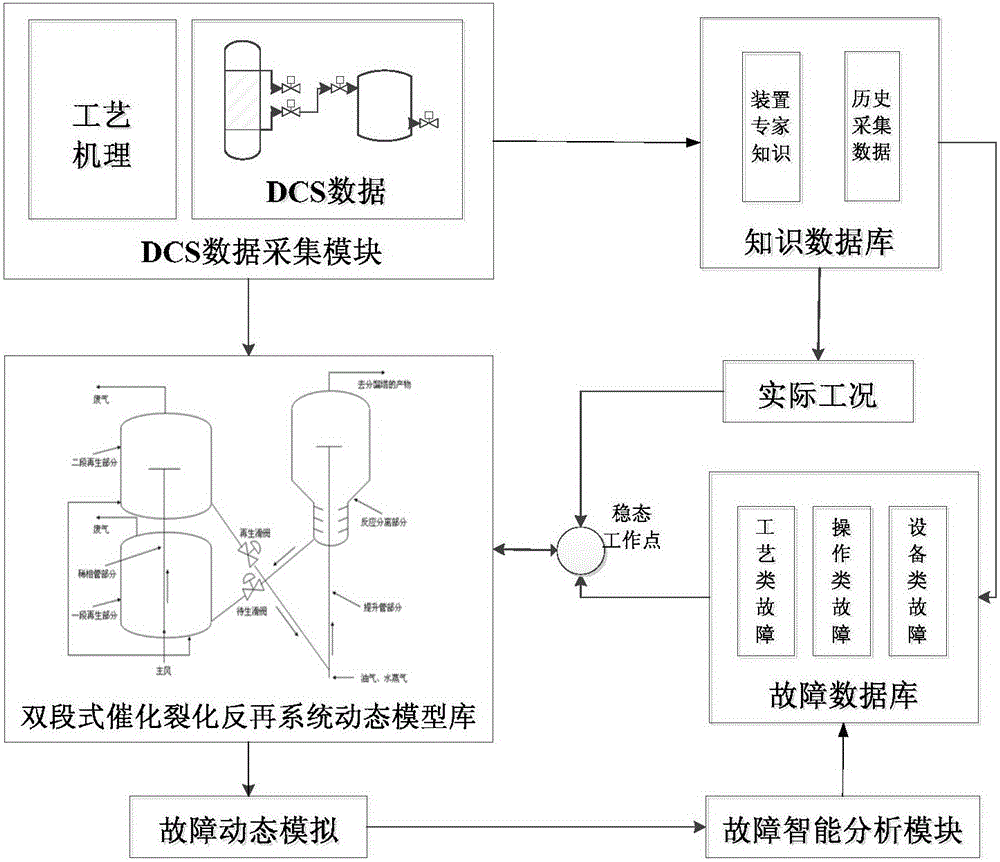

[0165] Such as figure 1 As shown, a dual-stage catalytic cracking anti-regeneration system fault dynamic simulation system includes: DCS data acquisition module, dual-stage catalytic cracking anti-regeneration system dynamic model library, knowledge database, fault database and fault intelligent analysis module.

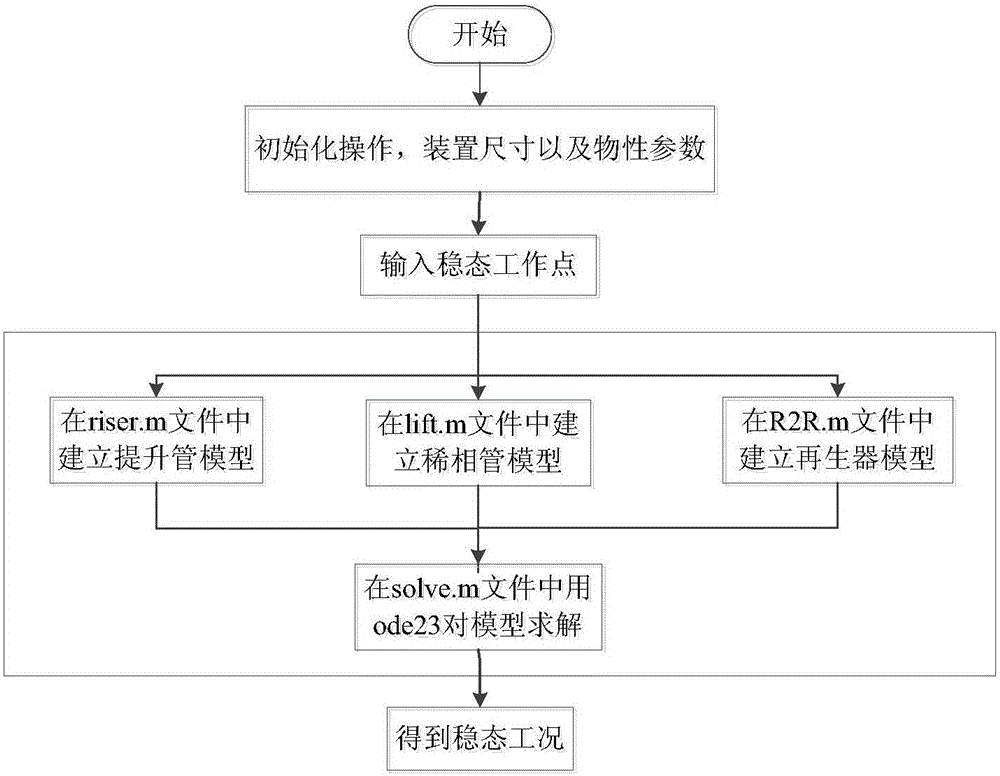

[0166] A two-stage catalytic cracking anti-regeneration system failure dynamic simulation method, including:

[0167] (1) Establish knowledge database and integrate fault database;

[0168] The establishment of the knowledge database includes:

[0169] ⅰ) At the initial stage of establishment, collect production equipment, safety equipment, hazard sources and production activities, complete basic knowledge collection, and obtain failure summary, as shown in Table 1;

[0170] Table 1 Summary of faults in the double-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com