Method for judging mining feasibility of middle residual coal in complex residual mining area

A discrimination method and technology of residual mining area, applied in the fields of instrument, data processing application, calculation, etc., can solve the problem of no systematic report on the recovery of residual coal in composite residual mining area, achieve huge market economic benefits, easy to master and apply , the effect of creating market economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

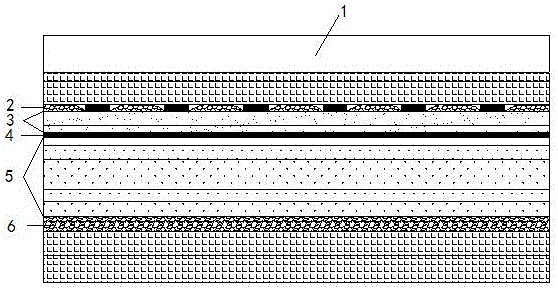

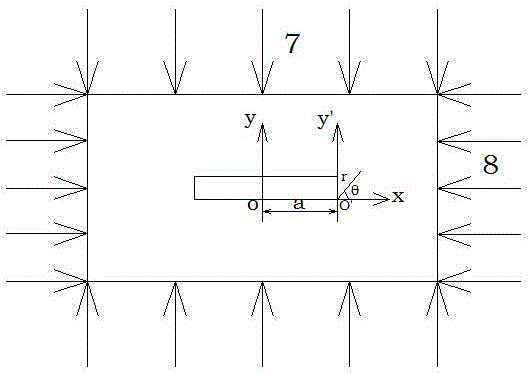

[0029] In the early coal recovery process, due to the limitation of geological conditions and mining equipment, many mining methods such as caving method and knife column method were adopted, so a large number of "upper knife column-bottom caving" composite residual mining areas were formed. Whether the residual coal in the central part of the residual mining area can be safely mined mainly depends on the distance between coal seams and the damage range caused by mining the upper and lower coal seams. Specific steps are as follows:

[0030] Step 1: Carry out drilling and coring in combination with the geological columnar map of the mining area, clarify the composition of the rock formations between the upper and lower coal seams in the composite residual mining area, and carry out unified labeling. Generally, the rock formations of different layers are layered with natural layers boundaries.

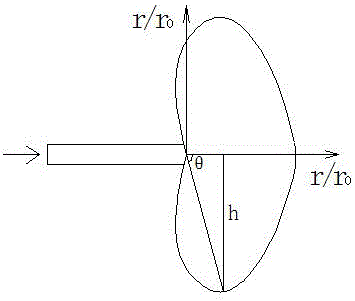

[0031] The second step: Combined with the basic theory of elastoplasticity, the max...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com