A pre-assembled joint-type submarine cable traction and anchoring integrated device

An articulated, pre-assembled technology, applied in cable laying equipment and other directions, can solve problems such as long construction time, economic loss, and increased difficulty, and achieve the effects of improving efficiency, facilitating system connection, and facilitating detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

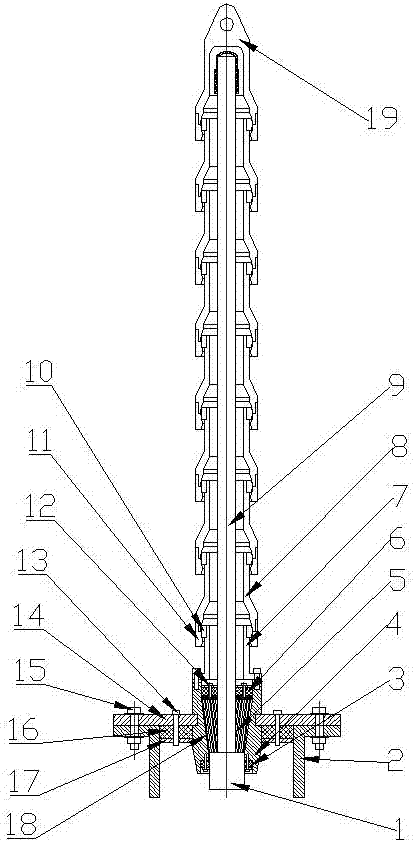

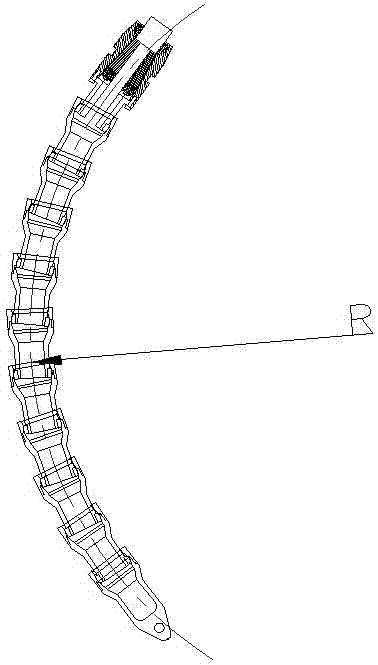

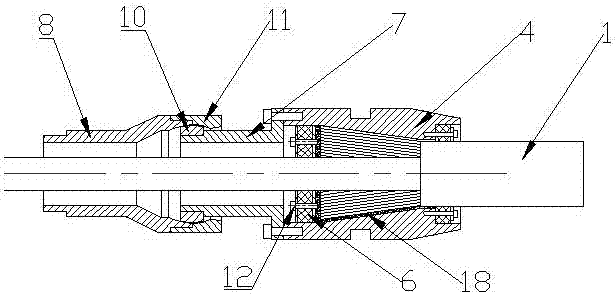

[0014] Such as Figure 1 to Figure 3 A pre-assembled joint-type submarine cable traction and anchoring integrated device is shown, including submarine cable 1, J tube (I tube) port 2, anchor sealing ring A 3, anchor base 4, armored steel wire 5, anchor Sealing ring B 6, connecting flange 7, connecting shaft 8, submarine cable without armor wire 9, bearing shaft 10, rear taper sleeve 11, bolt A 12, bolt B 13, flange 14, bolt C 15, buffer Gasket 16, backing plate 17, steel wire fastening glue 18, front taper sleeve 19. The inside of the anchor base 4 is filled with steel wire fastening glue 18, and the anchor seal ring B 6 at both ends, the anchor seal ring A 3 and the bolt A 12 are used together to improve the sealing performance of the anchor after locking; the flange 14 clamps the anchor base 4. Connect the J nozzle 2 through the bolt C 15; the connecting flange 7 is connected with the anchor base 4 through the screw; the bearing shaft 10 is a spherical surface, and is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com