A flexible cable accessory explosion-proof device and installation method

A technology for cable accessories and explosion-proof devices, which is applied in the direction of gas-filled/oil-filled cable accessories, overhead lines/cable equipment, etc., can solve the problems of not being able to fully adapt to emergency situations, not enough to accommodate cable accessories, and not being able to be changed, so as to increase explosion-proofing effect, reducing site or space limitations, and avoiding fire accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

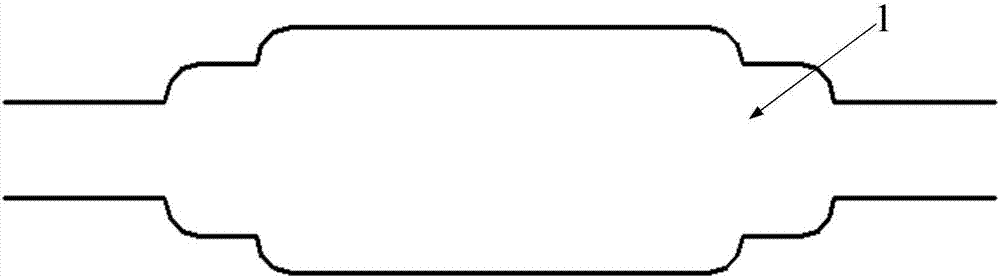

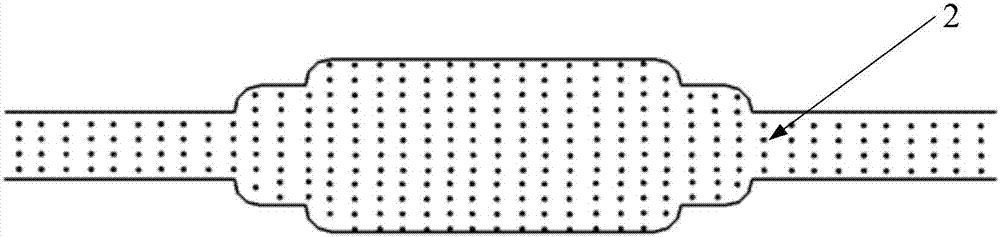

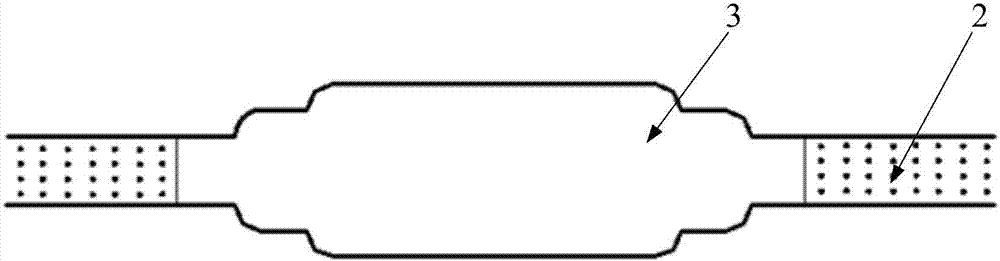

[0046] Installation of explosion-proof devices such as Figure 1(a) to Figure 1(d) shown. First, evenly wrap a layer of aluminum foil on the cable accessory 1 with a voltage level of 10kV or 20kV, and the winding length of the aluminum foil is 20% longer than that of the cable accessory 1. Afterwards, the flexible oil-filled tape 3 made of silicone rubber is filled with silicone oil and then evenly wound onto the aluminum foil of the cable accessory. The winding length of the flexible oil-filled tape 3 is 5% less than that of the aluminum foil wound on the cable accessory 1. When winding, the inner side of the flexible oil-filled belt 3 is in contact with the cable. After the winding is completed, wrap the nylon mesh cloth on the flexible oil-filled belt 3 evenly, and tie the excess parts on both sides of the nylon mesh cloth on the cable accessory 1 to complete the installation. .

[0047] The structure and size of the flexible oil-filled belt 3 are as follows: Figure 2(a...

Embodiment 2

[0051] On the basis of Example 1, the structure and material of the flexible oil-filled belt 3 are optimized, ethylene-propylene rubber is selected as the rubber, and mineral insulating oil is selected as the insulating oil. The structure of the new flexible oil-filled belt 3 is shown in Figure 3(a) and Figure 3(b), in which there are five oil-filled cells on the flexible oil-filled belt 3.

[0052] The thickness d1 of the first side wall is 1 cm, the height h of the oil-filled grid 5 is 1.5 cm, the thickness d2 of the second side wall is 2 cm, d1:h:d2=1:1.5:2.

[0053] In the oil-filled grid unit, the width f2 of the oil-filled grid 5 accounts for 12% of the length L1 of the flexible oil-filled belt 3, and the wall thickness f1 of the left side wall and the right side wall respectively accounts for 4% of the length L1 of the flexible oil-filled belt 3; The length f4 of the oil-filled grid 5 accounts for 80% of the width L2 of the flexible oil-filled belt 3 , and the wall thic...

Embodiment 3

[0056] On the basis of Example 2, the structure and material of the flexible oil-filled belt 3 are optimized, butadiene rubber is selected as the rubber, and vegetable insulating oil is selected as the insulating oil. The structure of the new flexible oil-filled belt 3 is shown in Figure 4(a) and Figure 4(b), in which there are 8 oil-filled grid units on the flexible oil-filled belt 3, and the specific dimensions are shown in the figure.

[0057] The thickness d1 of the first side wall is 1 cm, the height h of the oil-filled grid 5 is 1.5 cm, the thickness d2 of the second side wall is 2 cm, d1:h:d2=1:1.5:2.

[0058] In the oil-filled grid unit, the width f2 of the oil-filled grid 5 accounts for 8.5% of the length L1 of the flexible oil-filled belt 3, and the wall thickness f1 of the left side wall and the right side wall respectively accounts for 2% of the length L1 of the flexible oil-filled belt 3; The length f4 of the oil-filled grid 5 accounts for 68% of the width L2 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com