Suspension type motor cover assembly structure

A technology of component structure and motor cover, which is applied in the direction of electric components, electrical components, casing/cover/support, etc. Vibration noise reduction effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

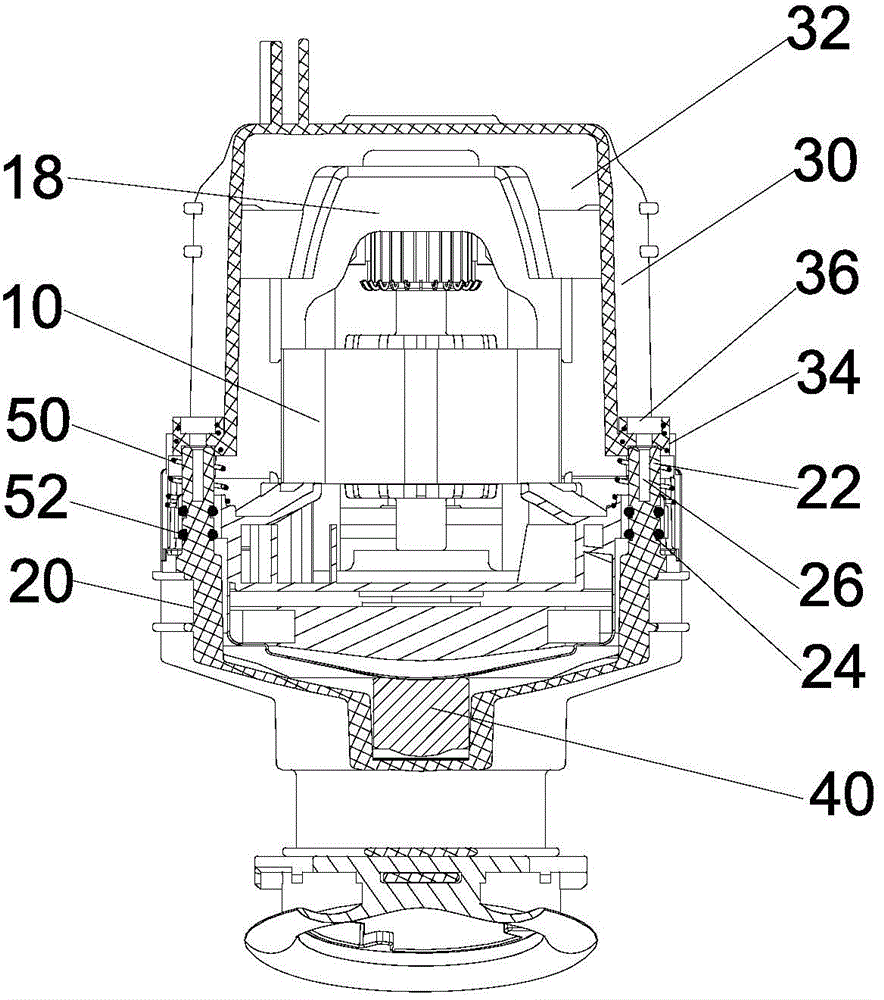

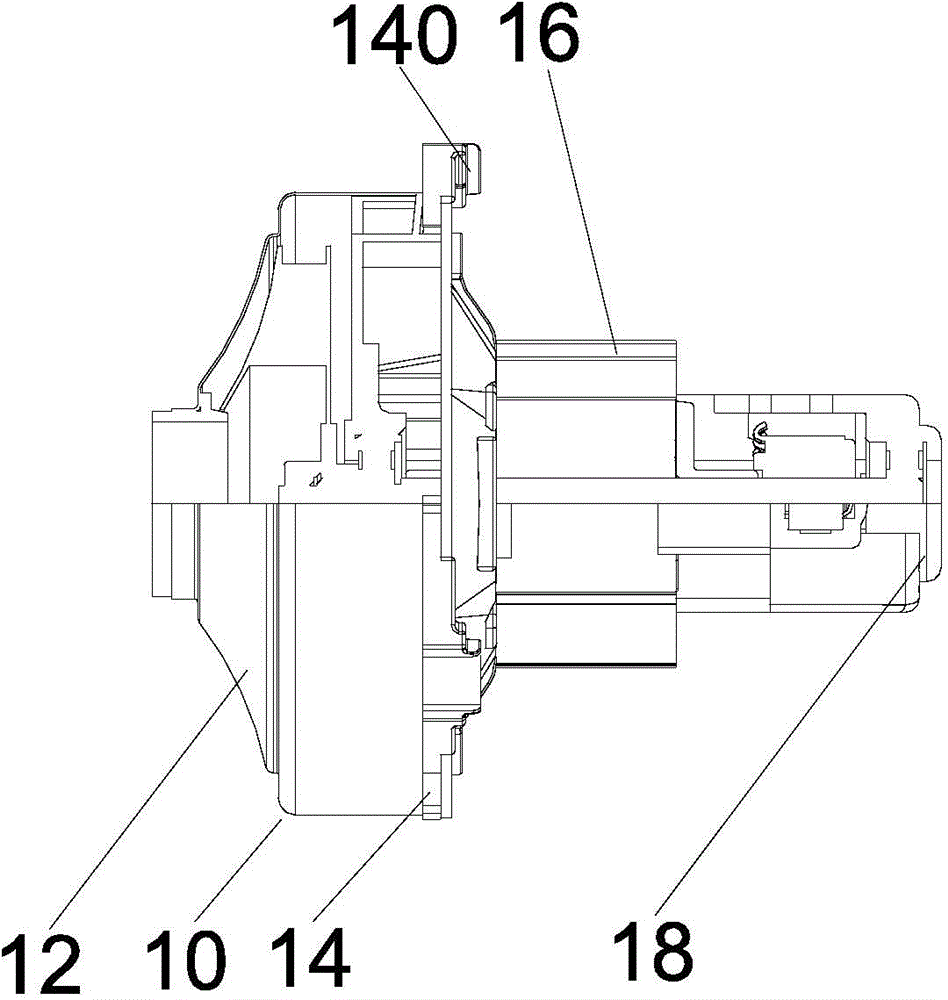

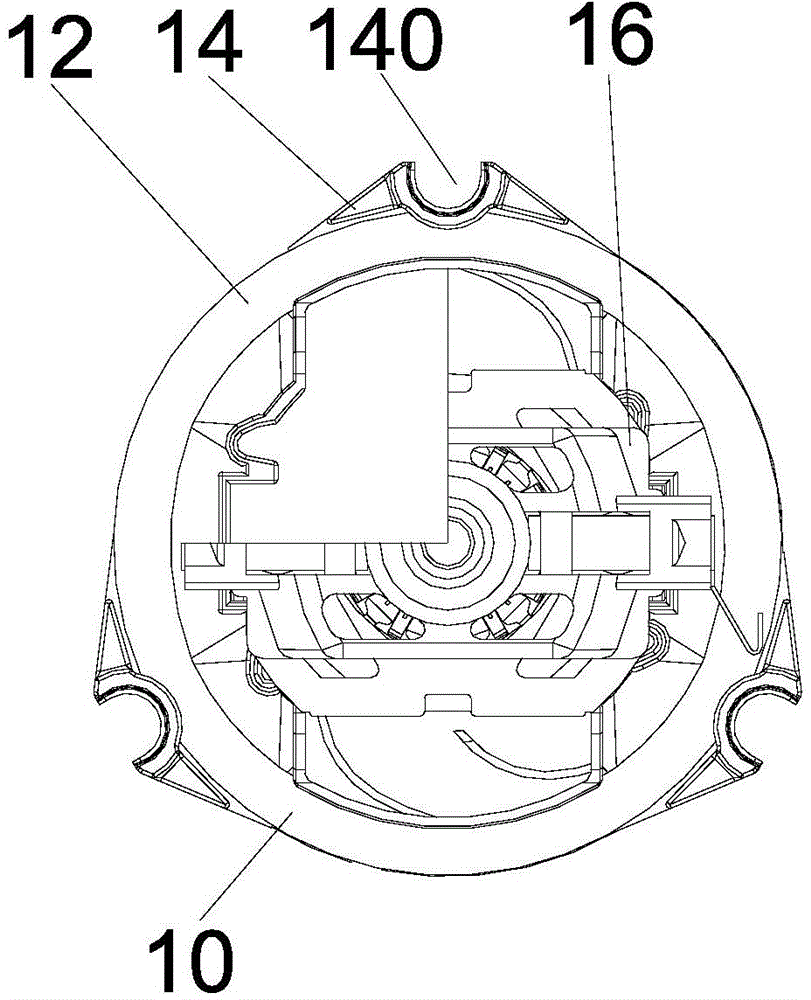

[0020] Example: such as Figure 1-3 As shown, the present invention provides a specific embodiment of a suspended motor cover assembly structure, which includes a motor 10 and a motor cover for accommodating the motor 10, wherein the motor cover includes a motor lower cover 20, and is fixedly connected with the motor lower cover 20 The upper cover 30 of the motor, and there is a cushioning space between the lower cover 20 of the motor or the upper cover 30 of the motor and the motor 10 .

[0021] The motor 10 includes a head 12 at one end, a tail 18 at the other end, a stator 16 between the head 12 and the tail 18 , and a stator 14 between the head 12 and the stator 16 . The fixed impeller 14 is provided with several perforations 140 on its edge. The perforation 140 is a closed hole or a semi-closed hole. The head 12 is used for motor air intake and has a moving impeller. When the motor 10 is working, the head 12 is located below, while the tail 18 is located above and susp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com