Preparation process of damping tire

A technology for shock-absorbing tires and manufacturing processes, which is applied in tire parts, tires, non-pneumatic tires, etc., can solve problems such as inability to apply, high price, and need to improve anti-skid performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

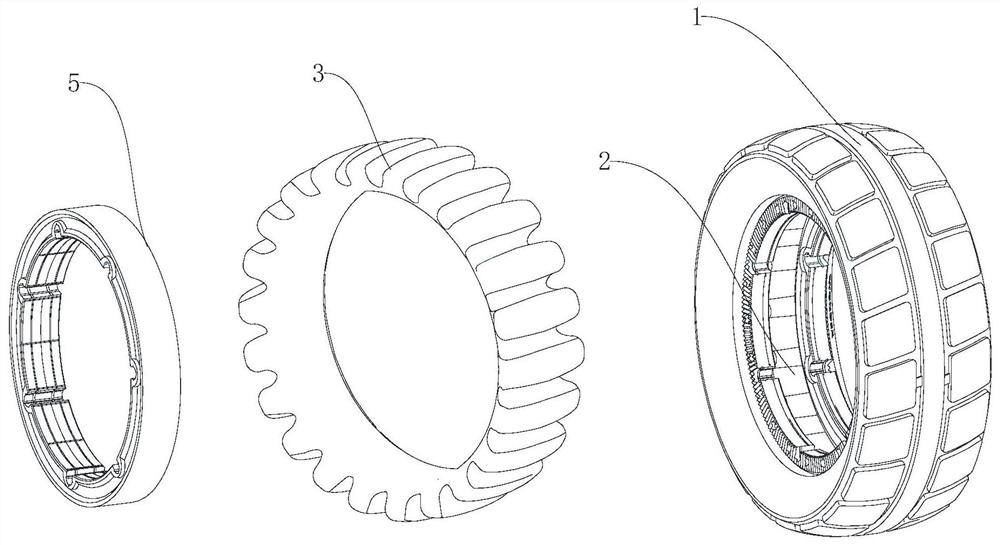

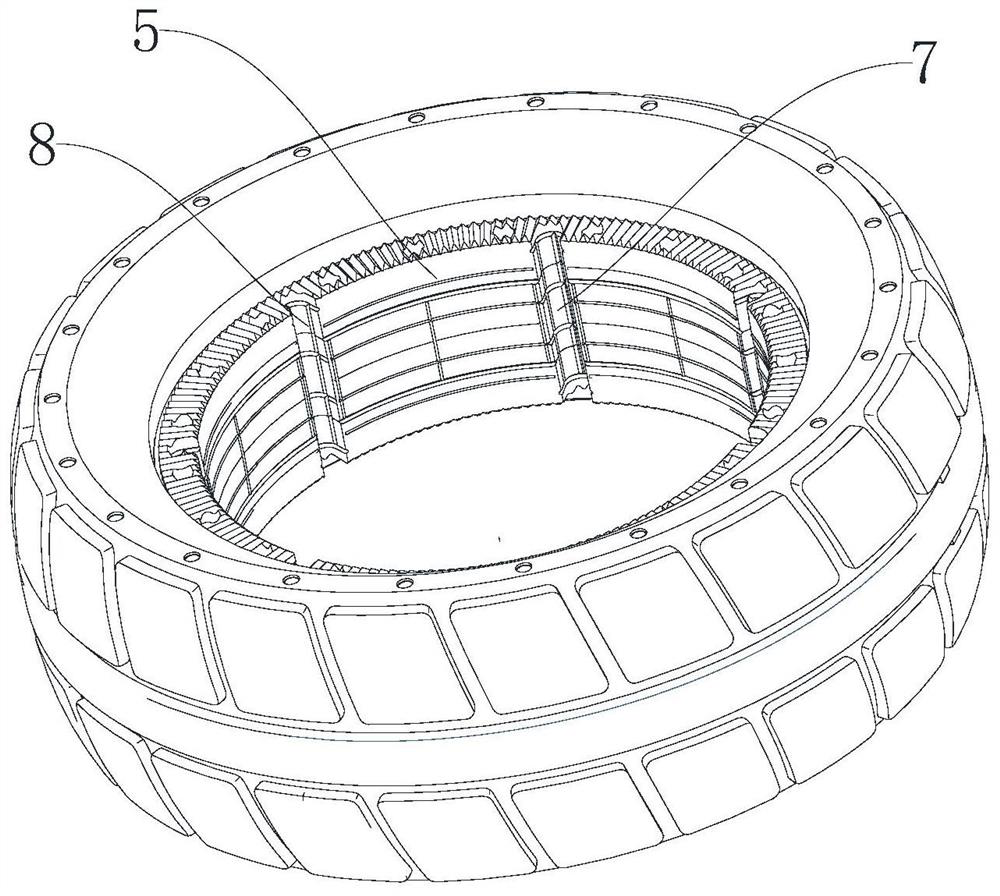

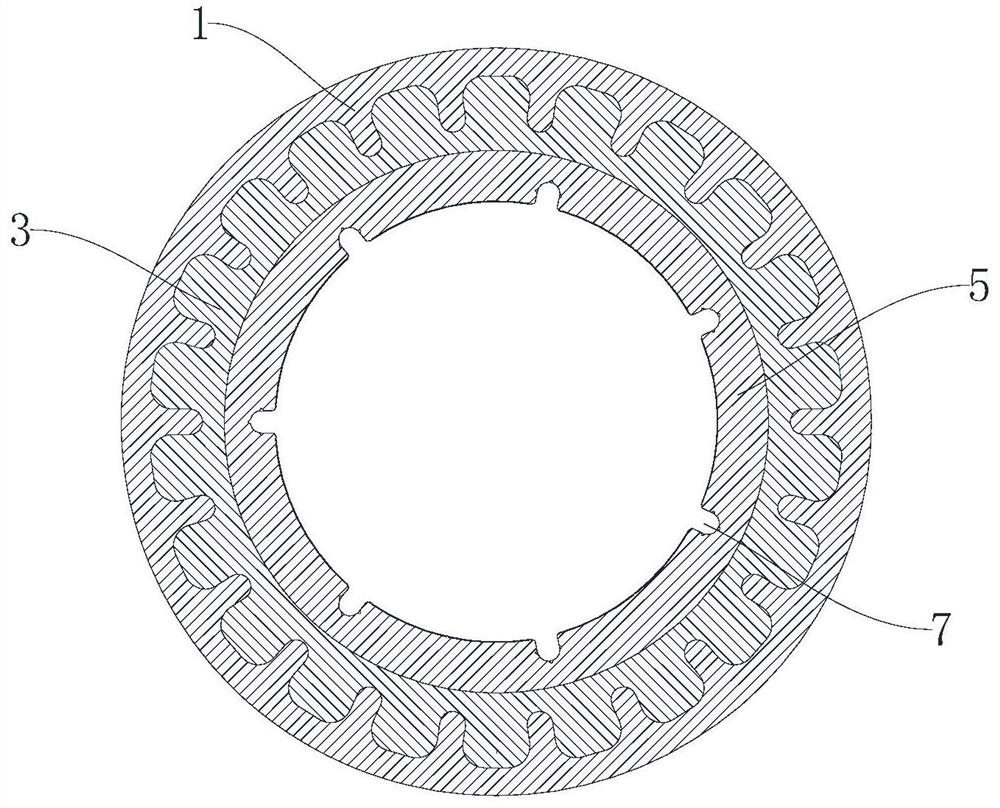

[0024] Embodiment: as shown in the figure, a kind of preparation technology of shock-absorbing tire, this shock-absorbing tire comprises cover tire body 1, and cover tire body 1 inside has cavity 2 coaxial with it, and cavity 2 is filled by an elastic body 3, cover tire The middle area of the inner side wall of the body 1 has an annular opening 4 coaxial with it, the elastic body 3 can only be exposed at the annular opening 4, and the annular opening 4 is embedded with an annular clamping strip 5 to close it, and the annular clamping strip 5 and the Cover tire body 1 is fixedly connected, and the material of cover tire body 1 is rubber or TPE, and cover tire body 1 is prepared by vulcanization process or injection molding process, and the specific technological process of this shock-absorbing tire comprises the following steps:

[0025] Step 1, first prepare a mold core whose structural size matches the cavity and the annular opening according to the designed cavity and annul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com