Plate fixing method and printing machine for implement same

A printing machine and printing plate technology, which is applied in the direction of printing machine, rotary printing machine, general parts of printing machinery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

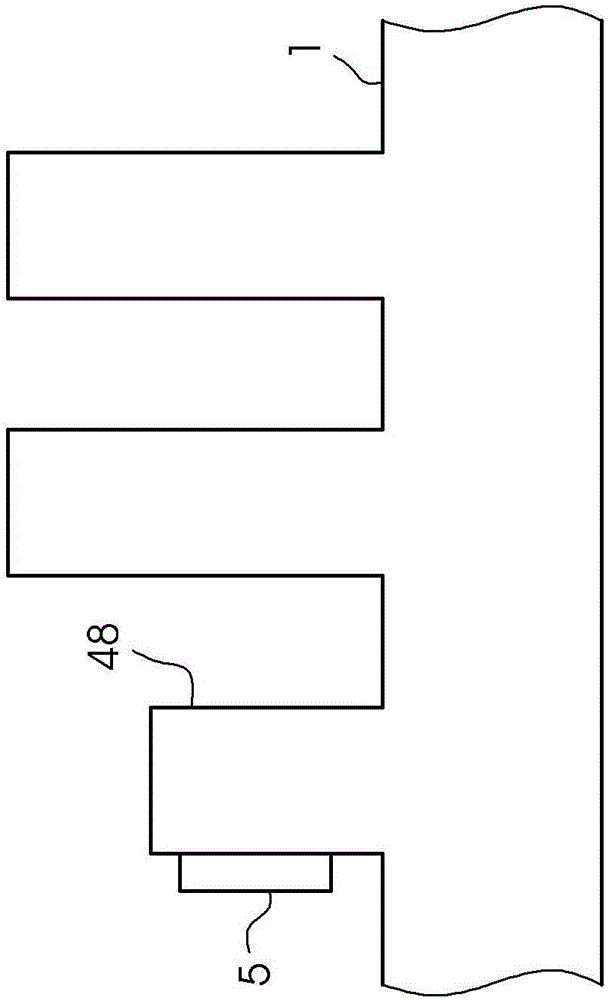

[0028] figure 1 A printing press 1 is shown which has an offset printing unit and a flexographic printing unit as varnishing unit 48 . The printing press is a sheet printing press with a feeder and a delivery not shown.

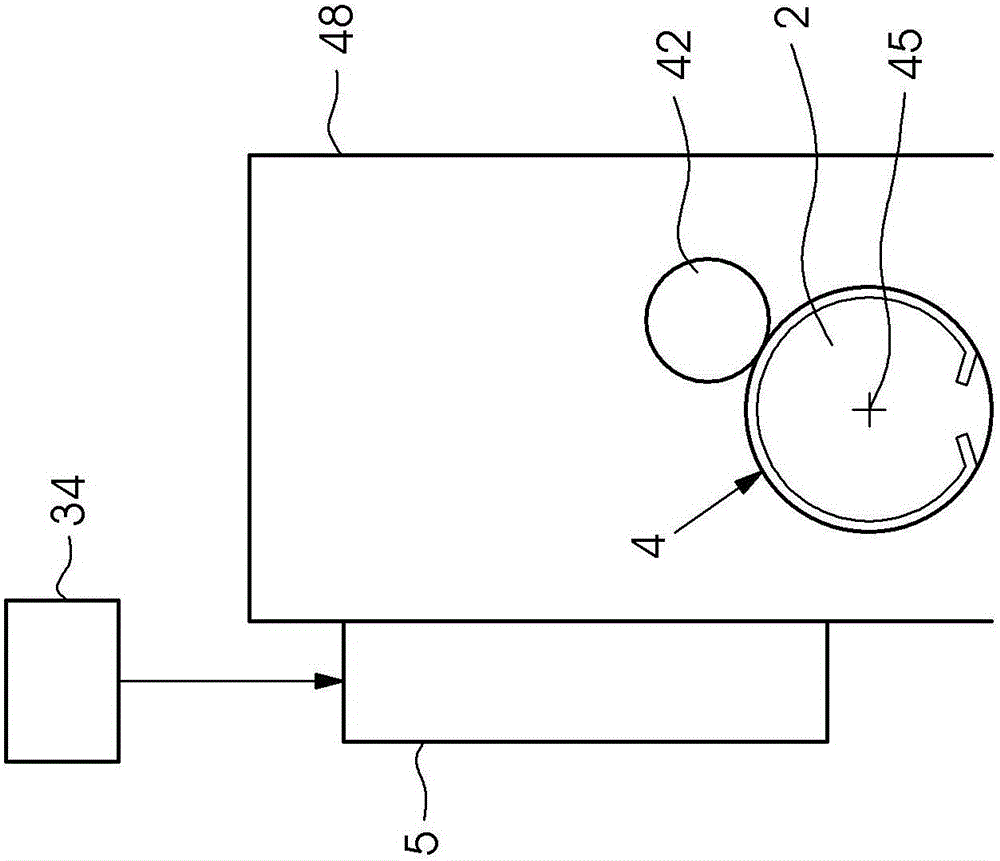

[0029] figure 2 It is shown that the coating unit 48 has the plate cylinder 2 and has the plate changer 5 for changing the printing plates 4 . Plate 4 is a flexographic plate for spot varnish. During printing operation, a roller 42 , which is both an application roller and an anilox roller, rolls on the printing plate 4 .

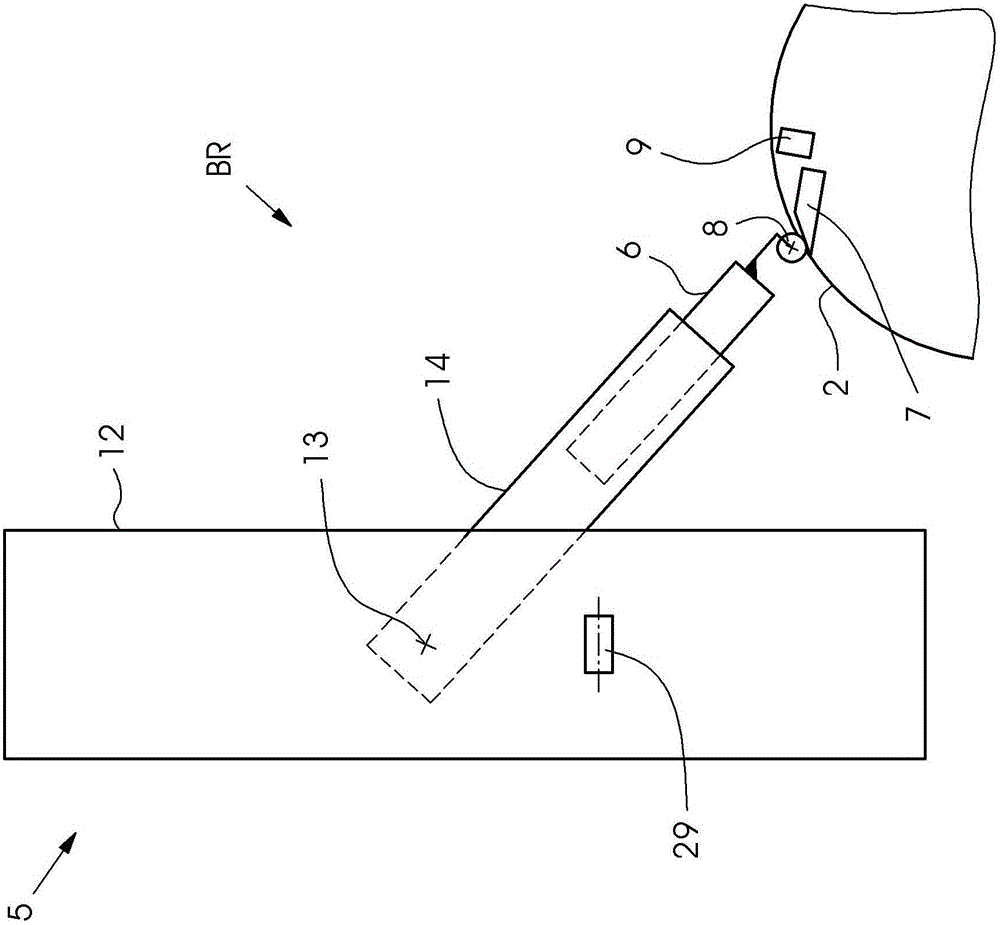

[0030] image 3 It is shown that the plate changer 5 has a plate guide 14 and a plate well 12 which extends vertically. The plate guide 14 is mounted in the hinge 13 and is foldable. The transport slide 6 is mounted displaceably in a printing plate guide 14 . The printing plate guide 14 is pivoted about the hinge 13 in order to adjust the printing plate guide 14 into the feeding position 46 (see FIG. 4 ). The printing plate guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com