A weighing and marking device for individual poultry eggs based on a conveyor belt

A technology for weighing devices and conveyor belts, applied to measuring devices, weighing, conveyors, etc., to achieve the effects of saving manpower, reducing manual workload, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

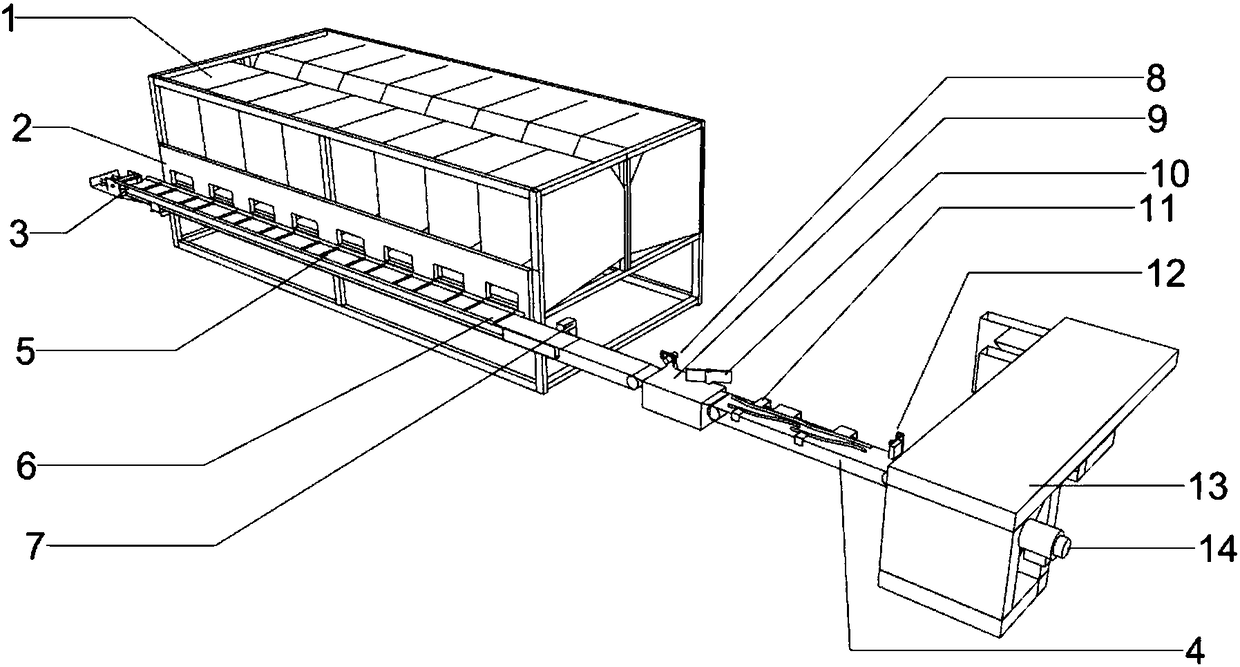

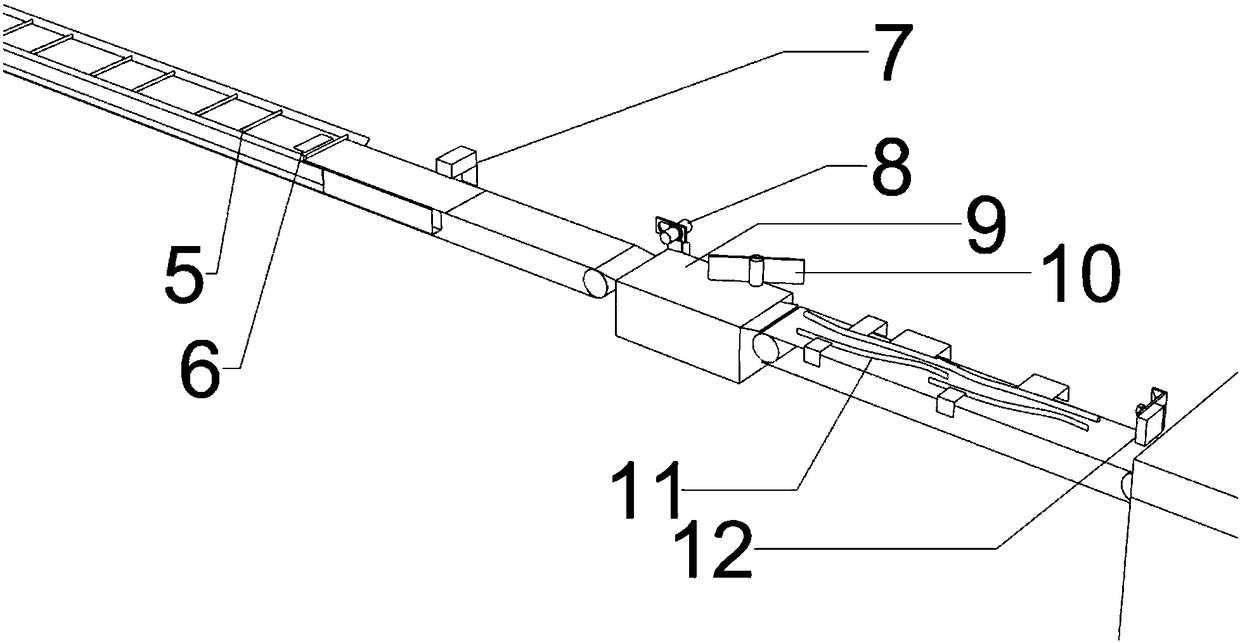

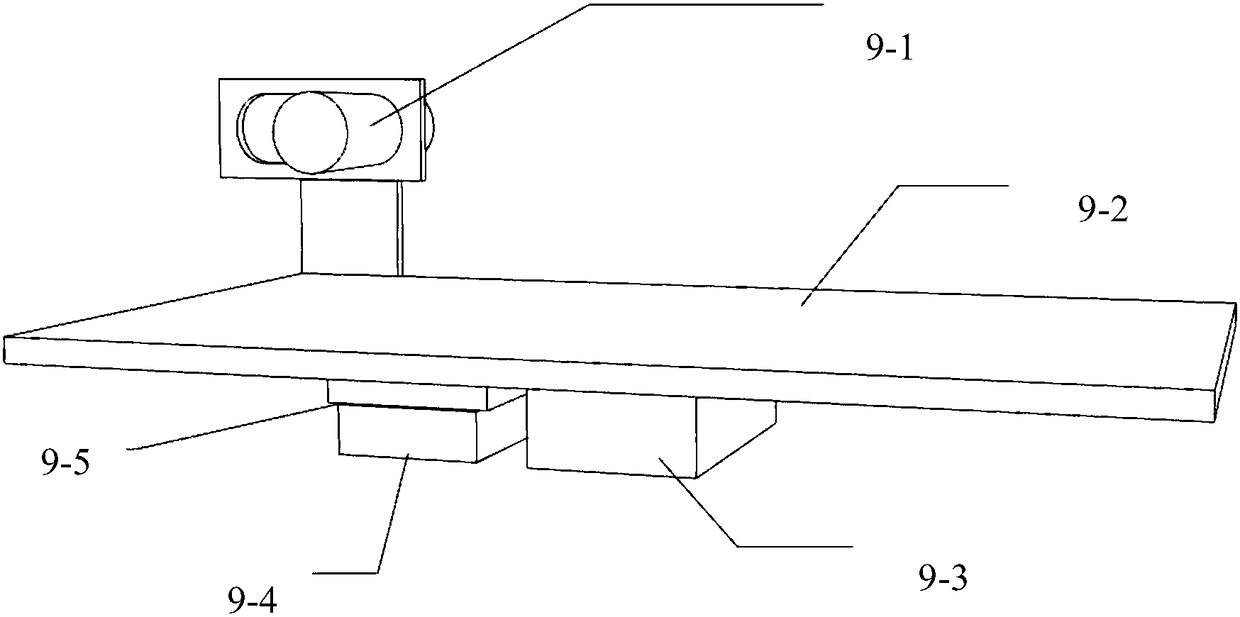

[0038] like figure 1 , which is a structural schematic diagram of an individual poultry egg weighing and marking device based on a conveyor belt in the present invention, figure 2 As shown, a partial structural schematic diagram of an individual poultry egg weighing and marking device based on a conveyor belt of the present invention. In the figure, 1 is the individual single cage, 2 is the egg outlet baffle, 3 is the first conveyor belt, 4 is the second conveyor belt, 5 is the conveyor partition, 6 is the IC card, 7 is the cantilever IC card reader, 8 9 is an egg weighing device, 10 is a rotary fork, 11 is a poultry egg positive shape device, 12 is a coding device, 13 is a poultry egg collection device, and 14 is a motor.

[0039]The present invention provides an individual poultry egg weighing and marking device based on a conveyor belt, comprising an individual single cage 1, an egg outlet baffle 2, a first conveyor belt 3, a second conveyor belt 4, a conveyor belt partit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com